Continuous production process method of hydroxyguanidine sulfate

A technology of hydroxyguanidine sulfate and production process, which is applied in the field of preparation process of hydroxyguanidine sulfate, can solve problems such as inability to directly react in one step, unfavorable continuous reaction, long reaction time, etc., achieve automatic continuous production, shorten reaction time, The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

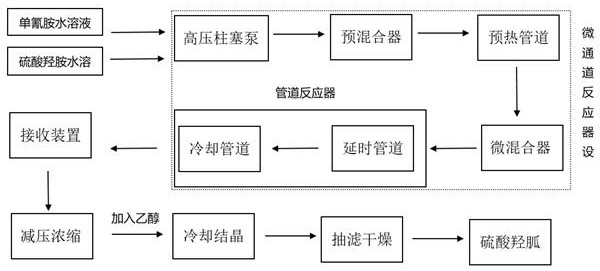

Image

Examples

Embodiment 1

[0028] Through the plunger pump, the mass fraction of 30% hydroxyguanidine sulfate aqueous solution and the mass fraction of 50% cyanamide aqueous solution are passed into the microchannel reactor at a mixing ratio of 1:1 (v / v) for condensation reaction, and the reaction temperature is 5 ° C. The reaction time is 300s, the reaction pressure is 1.2Mpa, and the reaction feed liquid containing hydroxyguanidine sulfate obtained after the reaction is completed. It is pumped into the concentrated crystallization kettle through a high-pressure plunger pump for concentration under reduced pressure, and ethanol is passed through to cool down and crystallize. The volume ratio of the ethanol solution and the concentrated solution is 1:5. Finally, centrifuge filtration and drying to obtain hydroxyguanidine sulfate, and the calculated product yield is 72.1%.

Embodiment 2-3

[0030] The difference from the production method in Example 1 is that the mass fraction of the cyanamide aqueous solution used in this example is 70% (Example 2) and 30% (Example 3).

Embodiment 4-5

[0032] The difference from Example 1 is that in this example, the reaction temperature is 0°C (Example 4) and 10°C (Example 5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com