Preparation process of copper alloy material for short-process lead frame

A short-process lead wire and preparation process technology, applied in the field of copper alloys, can solve problems such as inability to meet large-scale production efficiency and cost, and demanding work capacity requirements, and achieve good application value, increased strength, and excellent electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

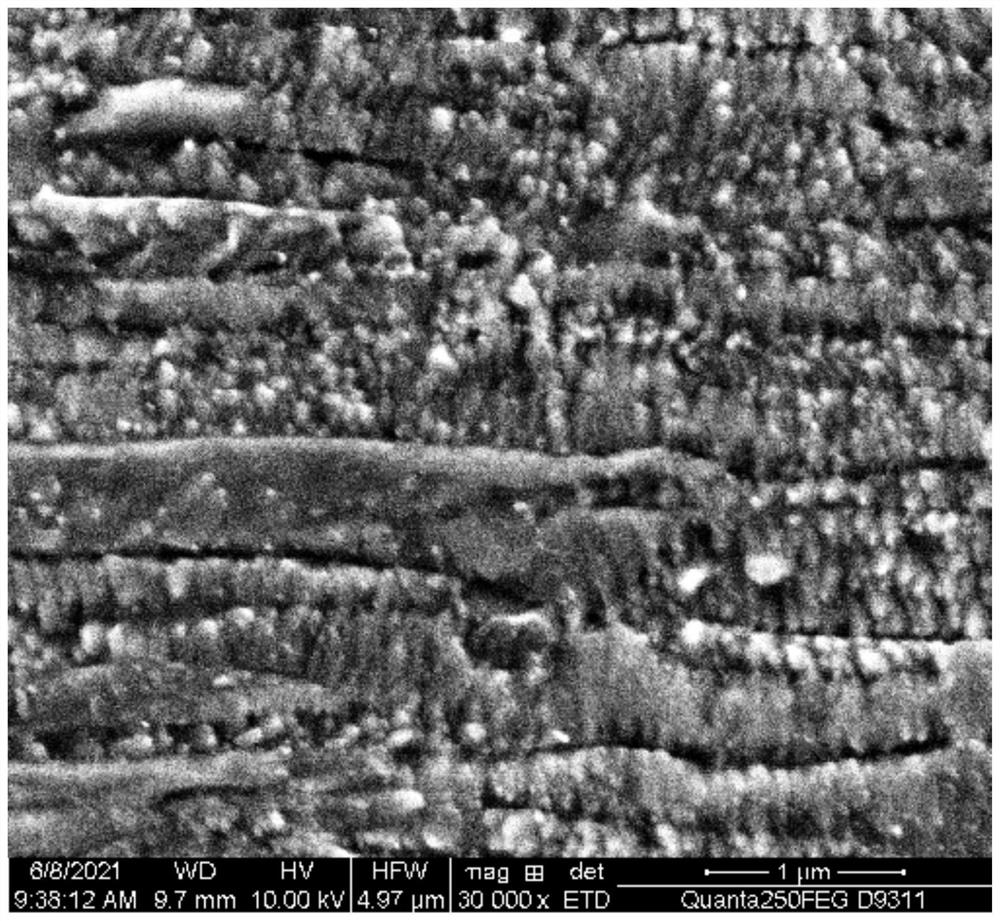

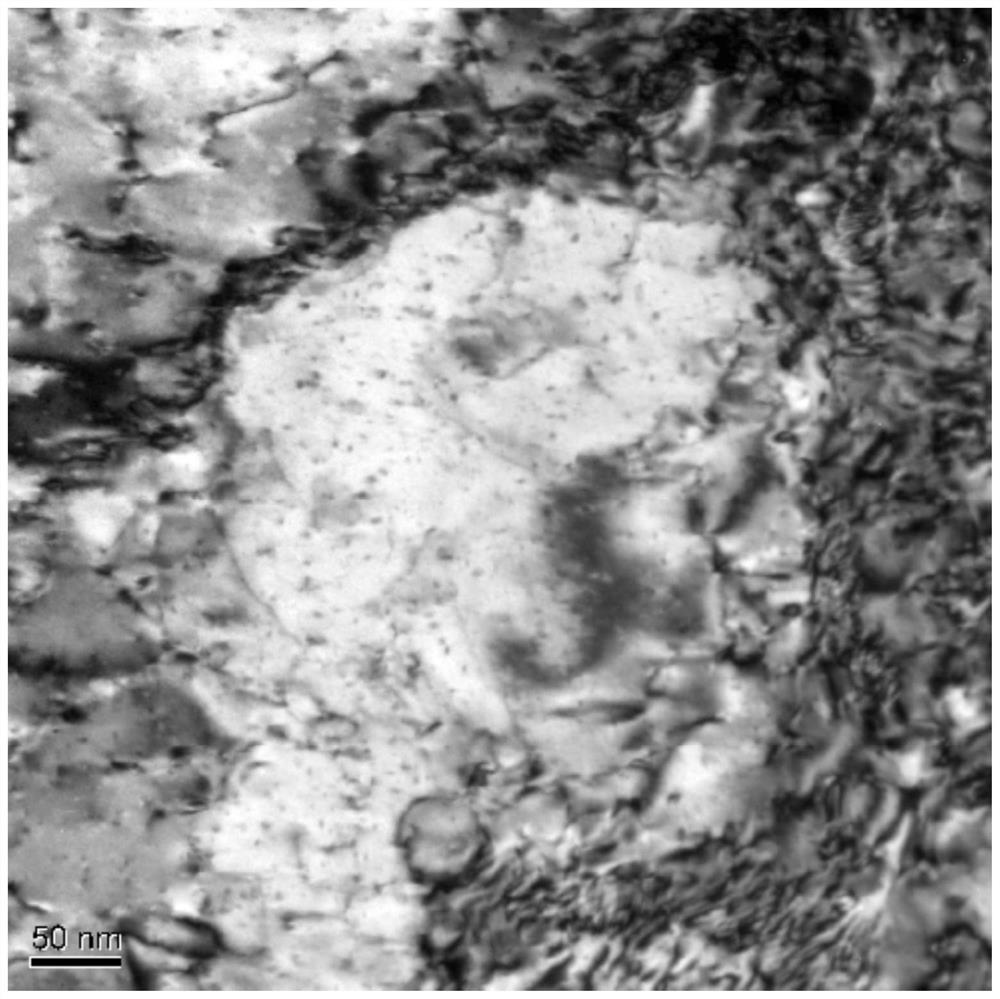

Image

Examples

Embodiment 1

[0025] The preparation process of the copper alloy material used for the short-flow lead frame of this embodiment includes the following steps in sequence:

[0026] (1) Vacuum induction melting: put high-purity oxygen-free copper (99.99wt.%), Cu-40Crwt.% master alloy, Cu-40Zrwt.% master alloy and pure Ag (99.99wt.%) into The crucible is smelted by vacuuming, and the degree of vacuum smelting is 3×(10 -4 ~10 -3 ) Pa, after the metal is completely melted, it is kept warm for 5 minutes, and the heat preservation temperature is 1150° C., and then it is cast into an ingot. The ingot composition of the copper alloy material in this embodiment is Cr: 0.7wt.%, Zr: 0.078wt.%, Ag : 0.1wt.%, impurity content ≤ 0.03wt.%, oxygen content ≤ 0.0008%, the balance is Cu;

[0027] (2) Hot forging treatment: the alloy ingot obtained in step (1) is placed in a holding furnace for homogenization treatment, the homogenization treatment temperature is 960 ° C, the homogenization treatment time is 4...

Embodiment 2

[0032] The preparation process of the copper alloy material used for the short-flow lead frame of this embodiment includes the following steps in sequence:

[0033] (1) Vacuum induction melting: put high-purity oxygen-free copper (99.99wt.%), Cu-40Crwt.% master alloy, Cu-40Zrwt.% master alloy and pure Ag (99.99wt.%) into The crucible is smelted by vacuuming, and the degree of vacuum smelting is 3×(10 -4 ~10 -3 ) Pa, after the metal is completely melted, it is kept warm for 5 minutes, and the heat preservation temperature is 1150° C., and then it is cast into an ingot. The ingot composition of the copper alloy material in this embodiment is Cr: 0.7wt.%, Zr: 0.078wt.%, Ag : 0.1wt.%, impurity content ≤ 0.03wt.%, oxygen content ≤ 0.0008%, the balance is Cu;

[0034] (2) Hot forging treatment: the alloy ingot obtained in step (1) is placed in a holding furnace for homogenization treatment, the homogenization treatment temperature is 960 ° C, the homogenization treatment time is 4...

Embodiment 3

[0039] The preparation process of the copper alloy material used for the short-flow lead frame of this embodiment includes the following steps in sequence:

[0040] (1) Vacuum induction melting: put high-purity oxygen-free copper (99.99wt.%), Cu-40Crwt.% master alloy, Cu-40Zrwt.% master alloy and pure Ag (99.99wt.%) into The crucible is smelted by vacuuming, and the degree of vacuum smelting is 3×(10 -4 ~10 -3 ) Pa, after the metal is completely melted, it is kept warm for 5 minutes, and the heat preservation temperature is 1150° C., and then it is cast into an ingot. The ingot composition of the copper alloy material in this embodiment is Cr: 0.7wt.%, Zr: 0.078wt.%, Ag : 0.1wt.%, impurity content ≤ 0.03wt.%, oxygen content ≤ 0.0008%, the balance is Cu;

[0041] (2) Hot forging treatment: the alloy ingot obtained in step (1) is placed in a holding furnace for homogenization treatment, the homogenization treatment temperature is 960 ° C, the homogenization treatment time is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com