Gas supply system and gas supply method of ion source

A technology of gas supply system and ion source, applied in the direction of container discharge method, pipeline system, container filling method, etc., can solve the problems of ion beam instability, increase the operating frequency of operators, and unstable gas flow, etc., to ensure processing The effect of improving quality, ensuring uniformity, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

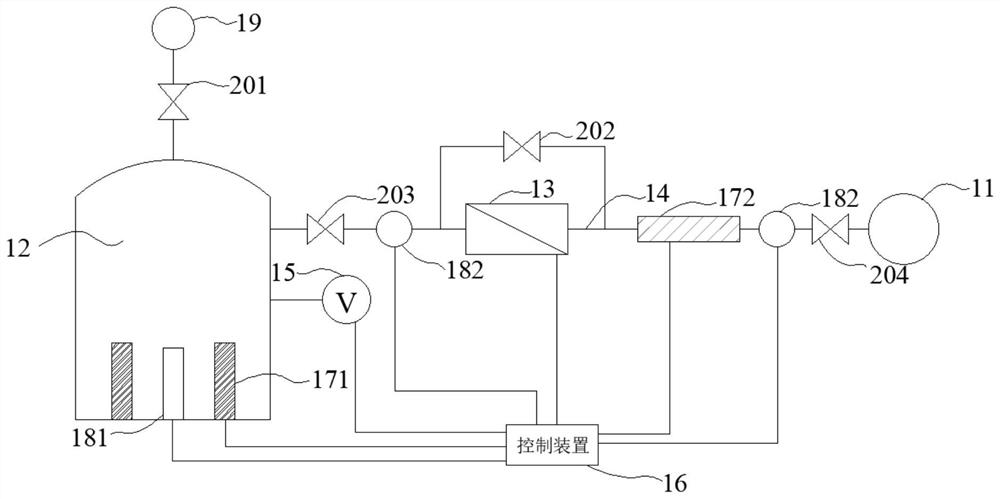

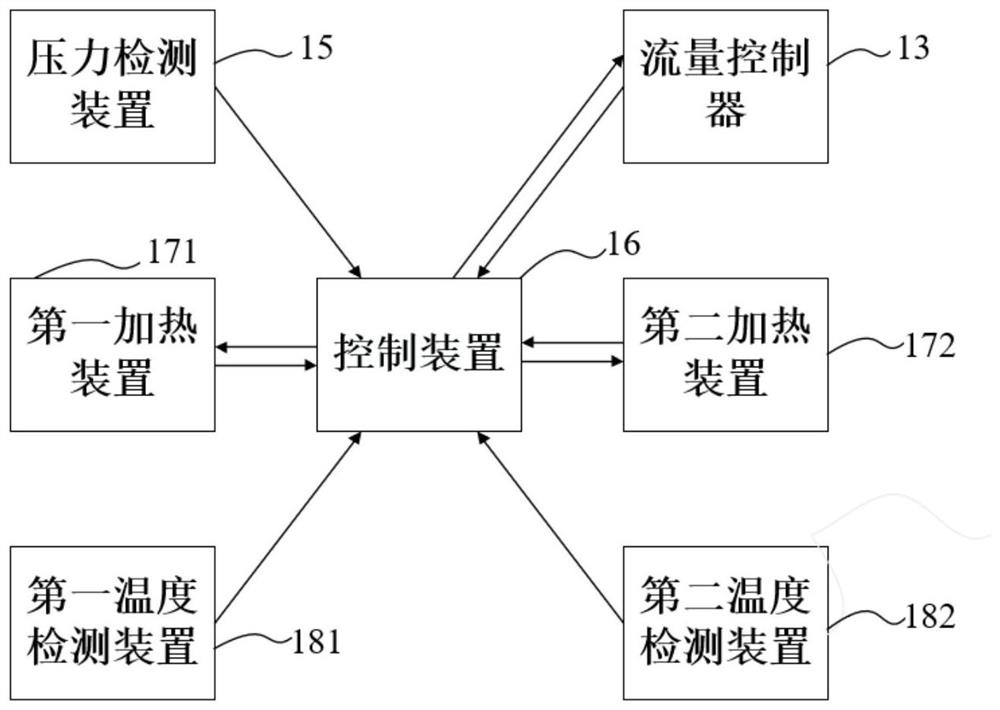

[0070] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0071] As used in this specification, the singular forms "a", "an" and "the" include plural referents unless the content clearly dictates otherwise. As used in this specification, the term "or" is generally employed in its sense including "and / or" unless the content clearly dictates otherwise. As used in this specification, the terms "first", "second", etc. are used for descriptive purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly specifying the quantity of indicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com