Cobalt-free lithium-rich positive electrode material, and preparation method and application thereof

A lithium-rich cathode material, lithium source technology, applied in the direction of positive electrode, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor cycle stability, voltage drop, serious gas production of high-nickel materials, restricting industrialization development, etc. The effect of stable cycle performance, improved cycle stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

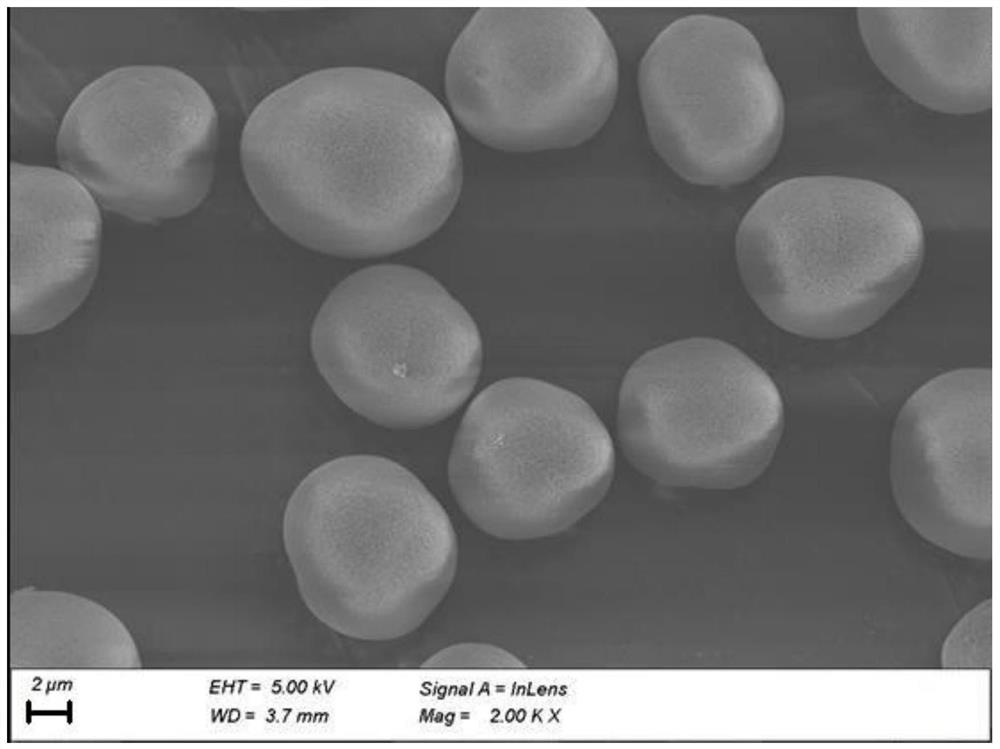

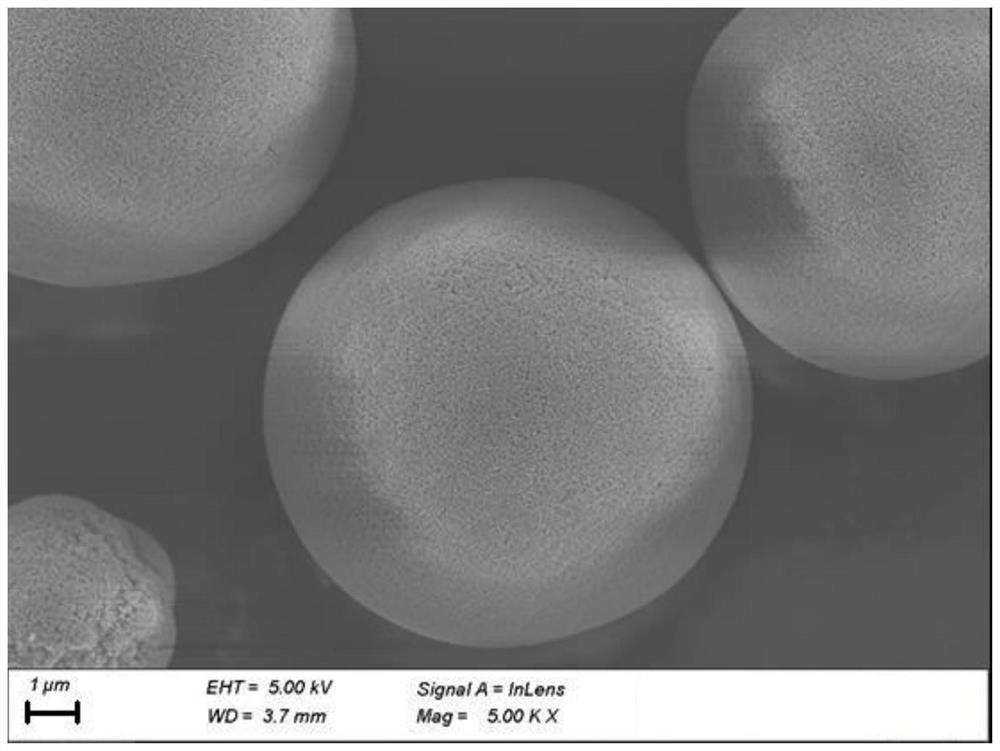

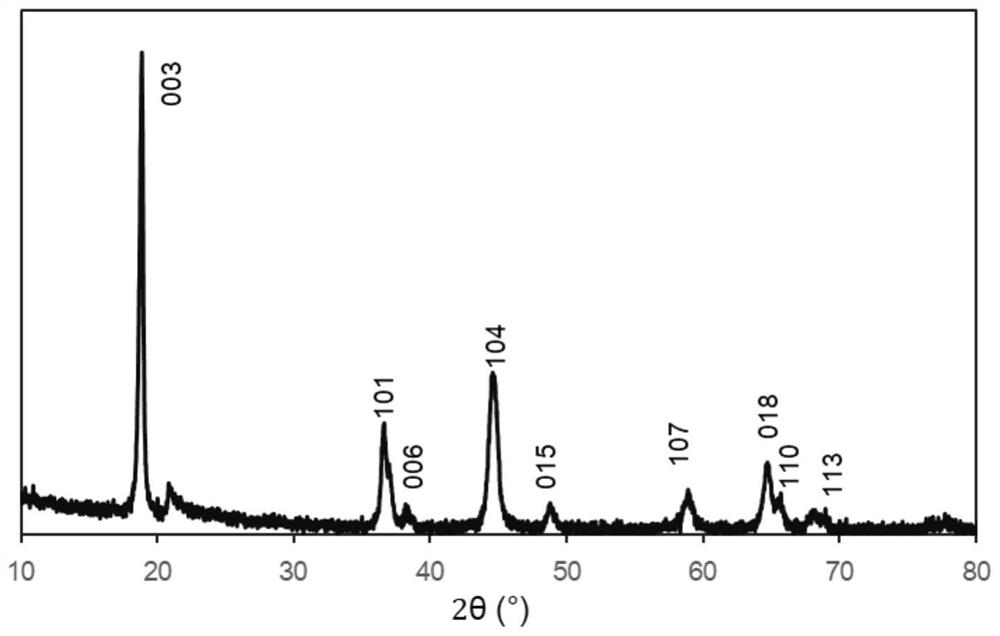

[0051] This embodiment provides a method for preparing a cobalt-free lithium-rich positive electrode material, which specifically includes the following steps:

[0052] (I) According to the molar ratio of manganese in manganese formate to nickel in Ni-MOF is 7:3, the particle size of Ni-MOF is 300nm, manganese formate and Ni-MOF are mixed, under air atmosphere, at 300℃ Carry out a calcination for 5 hours at a heating rate of 3°C / min to prepare a nickel-manganese matrix;

[0053] (II) Mix the nickel-manganese matrix obtained in step (I) with lithium oxalate, the molar ratio of the lithium element in the lithium source to the total metal elements in the nickel-manganese matrix is 1.2:1, in a compressed air atmosphere with a flow rate of 5L / min , carry out secondary calcination at 800°C for 10h, and the heating rate is 2°C / min, to obtain a lithium nickel manganese oxide matrix;

[0054] (Ⅲ) the lithium nickel manganese oxide matrix that step (Ⅱ) obtains and ZrB 2 Mixing, the ...

Embodiment 2

[0057] This embodiment provides a method for preparing a cobalt-free lithium-rich positive electrode material, which specifically includes the following steps:

[0058] (I) According to the molar ratio of manganese in manganese formate to nickel in Ni-MOF is 2:1, manganese formate and Ni-MOF are mixed, the particle size of Ni-MOF is 100nm, under air atmosphere, at 200℃ Carry out one calcination for 6 hours, the heating rate is 2°C / min, and prepare the nickel-manganese matrix;

[0059] (II) Mix the nickel-manganese matrix obtained in step (I) with lithium benzoate. The molar ratio of the lithium element in the lithium source to the total metal elements in the nickel-manganese matrix is 1:1, and the flow rate is 4L / min. Compressed air atmosphere In the process, the secondary calcination was carried out at 750°C for 12 hours, and the heating rate was 1°C / min to obtain a lithium nickel manganese oxide matrix;

[0060] (Ⅲ) the lithium nickel manganese oxide matrix that step (Ⅱ) ...

Embodiment 3

[0063] This embodiment provides a method for preparing a cobalt-free lithium-rich positive electrode material, which specifically includes the following steps:

[0064] (I) According to the molar ratio of manganese in manganese formate to nickel in Ni-MOF is 2.5:1, manganese formate and Ni-MOF are mixed, the particle size of Ni-MOF is 500nm, under air atmosphere, at 400℃ Perform a calcination for 4 hours at a heating rate of 4°C / min to prepare a nickel-manganese matrix;

[0065] (II) Mix the nickel-manganese matrix obtained in step (I) with lithium formate. The molar ratio of the lithium element in the lithium source to the total metal elements in the nickel-manganese matrix is 1.5:1. , carry out secondary calcination at 850°C for 10h, and the heating rate is 3°C / min, to obtain a lithium nickel manganese oxide matrix;

[0066] (Ⅲ) the lithium nickel manganese oxide matrix that step (Ⅱ) obtains and ZrB 2 Mixing, the zirconium source accounts for 1.0% of the mass of the lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com