Purification material and purification bed layer for chemical oxygen generator

A technology for oxygen generators and purification materials, which is applied in the direction of gas generation devices, chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of shortened filter material length, difficult processing and implementation, and difficult purification at the same time, so as to improve the quality , High impurity gas content, cost control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] The two layers of carbon monoxide purification material 4 in Example 2 are respectively a Hopcalite catalyst and a noble metal catalyst with platinum and palladium as active components.

Embodiment 3

[0049] The two layers of carbon monoxide purification material 4 in Example 3 are noble metal catalysts with platinum and palladium as active components.

Embodiment 1

[0051] A purification material for a chemical oxygen generator: composed of 20g of soda lime and 140g of a noble metal catalyst with platinum and palladium as active components.

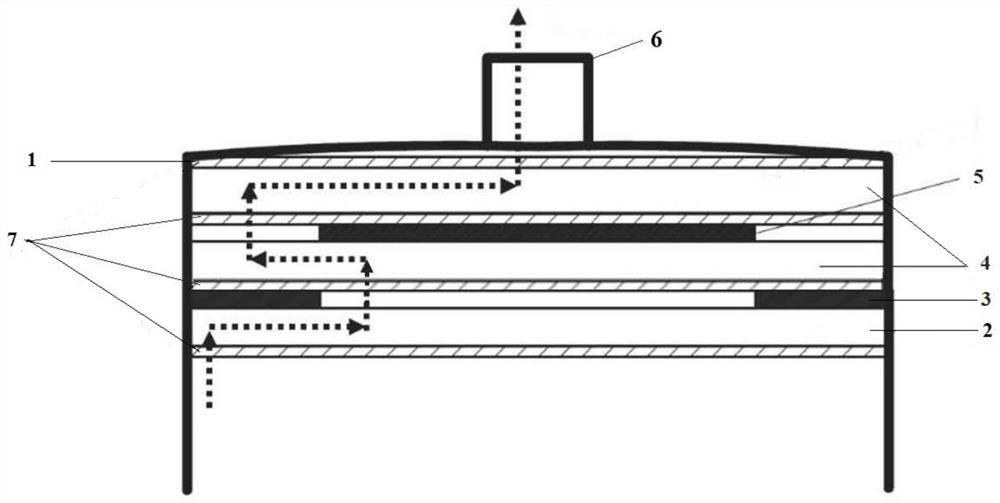

[0052] A kind of purification bed layer that is used for chemical oxygen generator, comprises the purification material that is used for chemical oxygen generator of the present embodiment, described purification bed layer is from top to bottom: glass fiber blanket, 140g uses platinum and palladium as active The precious metal catalyst of the components, glass fiber blanket, 20g soda lime, glass fiber blanket, the total height of the purification bed is 60mm, and the diameter is 70mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com