Ferric alginate-sodium citrate gel material as well as preparation method and application thereof

A technology of sodium citrate and gel materials, applied in chemical instruments and methods, water/sludge/sewage treatment, organic compounds/hydrides/coordination complex catalysts, etc. The speed current utilization rate and the treatment effect are not ideal, and the preparation method is simple, the reaction activity is enhanced, and the catalytic effect is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of alginate iron salt-sodium citrate gel material, and the method comprises the following steps:

[0029] 1) Preparation of sodium alginate aqueous solution, FeSO 4 ·7H 2 A mixed aqueous solution of O and sodium citrate;

[0030] 2) Add sodium alginate solution dropwise to FeSO 4 ·7H 2 In the mixed aqueous solution of O and sodium citrate, leave standstill to react afterwards;

[0031] 3) After the reaction is finished, post-treatment is carried out to obtain the iron alginate-sodium citrate gel material.

[0032] In step 1), in the sodium alginate aqueous solution, the mass concentration of sodium alginate is 1-1.3g / 100ml. FeSO 4 ·7H 2 In the mixed aqueous solution of O and sodium citrate, the molar concentration of sodium citrate is 0.1-0.2mmol / L, FeSO 4 ·7H 2 The molar concentration of O is 0.1-0.15mol / L.

[0033] In step 2), FeSO 4 ·7H 2 The mass ratio of O to sodium alginate is (2.7-3.5):1. Use a need...

Embodiment 1

[0038] 1) Preparation of gel material

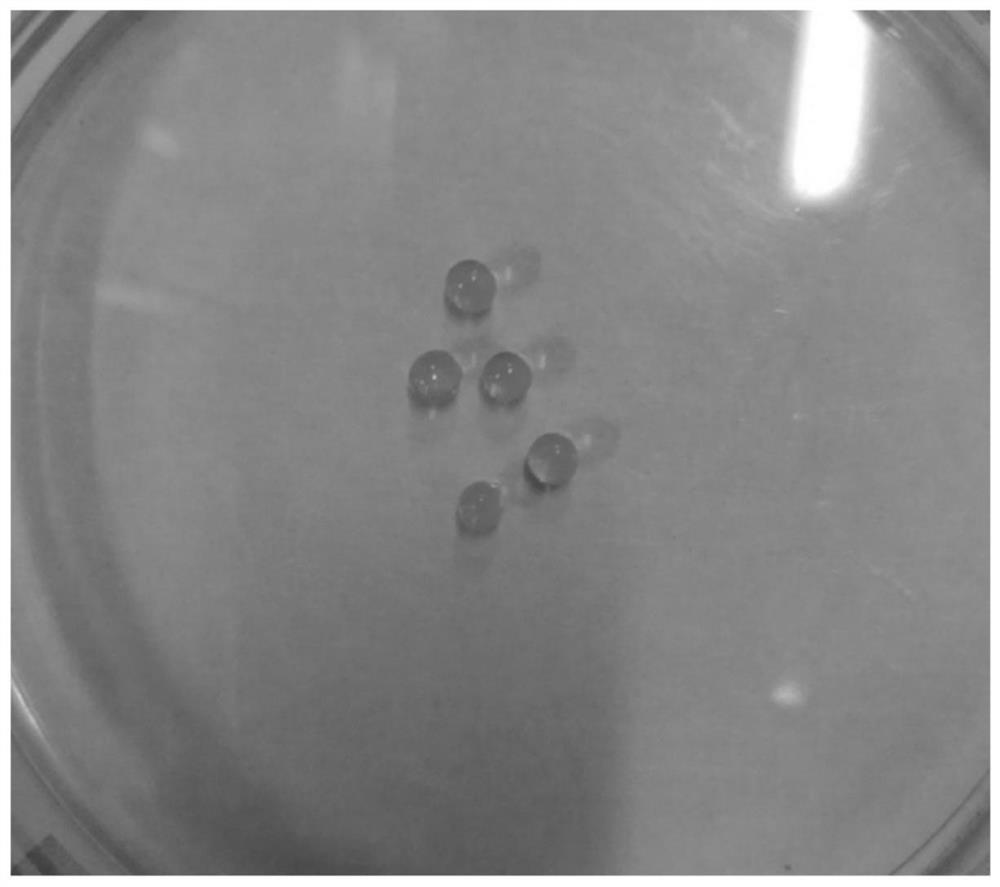

[0039] Weigh 1g of sodium alginate and dissolve it in 100ml of deionized water to obtain an aqueous solution of sodium alginate; 4 ·7H 2 O was added to 100ml of water, and 0.01mmol sodium citrate was added to obtain a mixed aqueous solution; the above two solutions were mixed with a needle dropwise, and then left to stand at a temperature of 32°C for 24 hours , the obtained product was washed with water and ethanol, and dried under vacuum at 40° C. for 4 hours to obtain a gel material. Depend on figure 1 It can be seen that the prepared gel material is spherical.

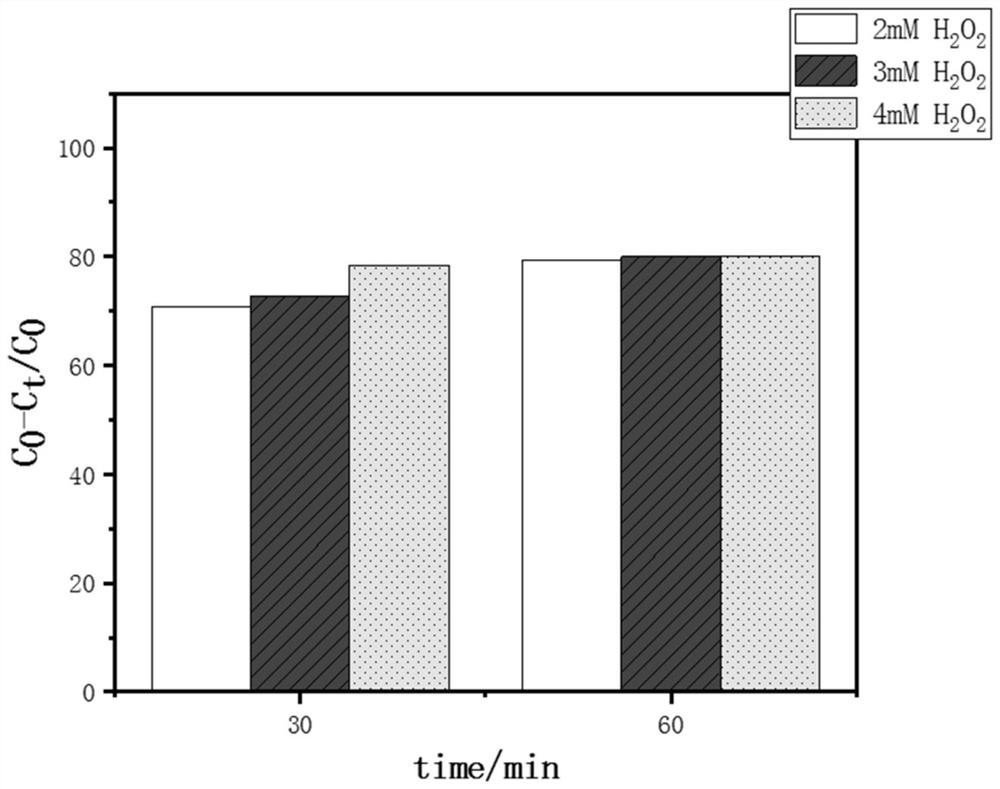

[0040] 2) Application of gel material

[0041] The gel material obtained in step 1) was added to 5mL of phenol waste water in an amount of 12g / l, wherein the phenol concentration was 20mg / L, and the hydrogen peroxide concentration was 2mM. A sample was taken every 30min, and another sample was taken after 60min. Sent to high performance liquid chromatography analysis.

...

Embodiment 2

[0044] 1) Preparation of gel material

[0045] Weigh 1.2g sodium alginate and dissolve in 100ml deionized water to obtain sodium alginate aqueous solution; 0.013molFeSO 4 ·7H 2 O was added to 100ml of water, and 0.01mmol sodium citrate was added to obtain a mixed aqueous solution; the above two solutions were mixed with a needle dropwise, and then left to stand at a temperature of 32°C for 24 hours , the obtained product was washed with water and ethanol, and dried in vacuum at 40° C. for 6 hours to obtain a gel material.

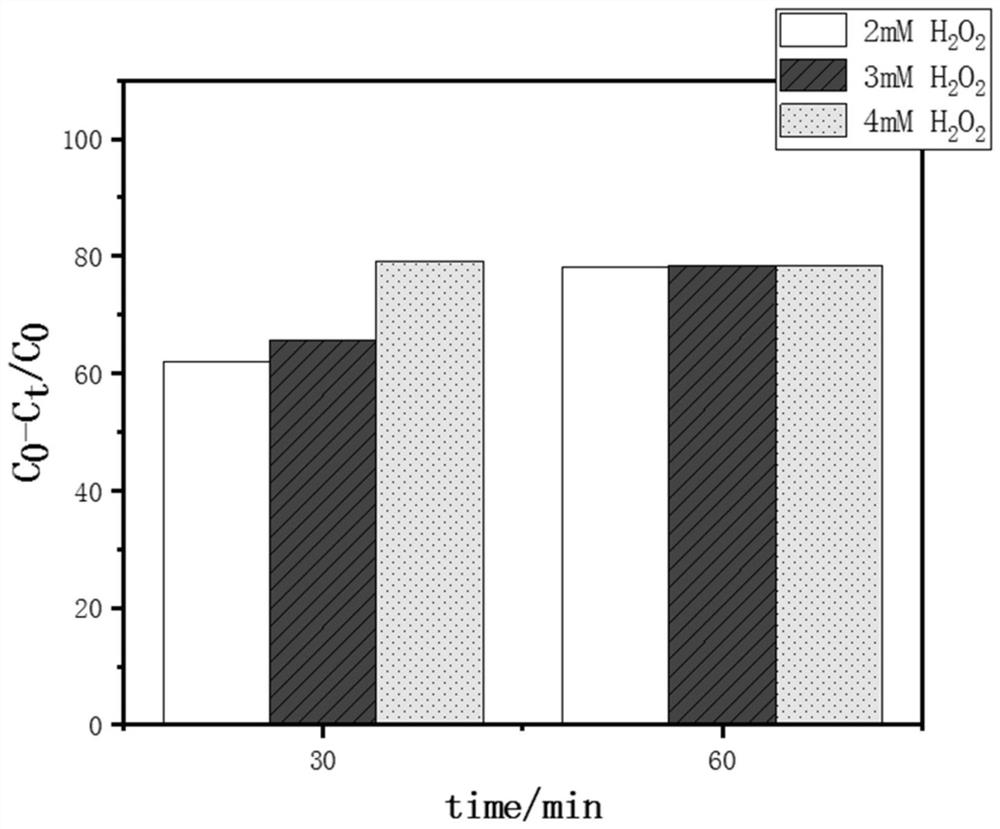

[0046] 2) Application of gel material

[0047] Add the gel material obtained in step 1) into 5mL of phenol waste water in an amount of 12g / l, wherein the phenol concentration is 20mg / L, and the hydrogen peroxide concentration is 3mM. A sample is taken every 30min, and a sample is taken again after 60min. Sent to high performance liquid chromatography analysis.

[0048] Depend on figure 2 It can be seen that under the catalysis of the gel material in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com