Mixed nutritional denitrification method based on sulfur reduction and sulfur autotrophic denitrification

A technology of mixed nutrition and sulfur autotrophy, applied in chemical instruments and methods, water treatment of special compounds, water pollutants, etc., can solve the problems of ignoring the whole system and synergistic effect of a single one, so as to improve the denitrification effect and avoid new Effects of pollution and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

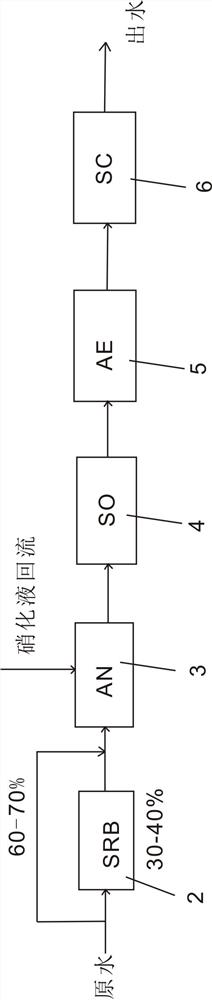

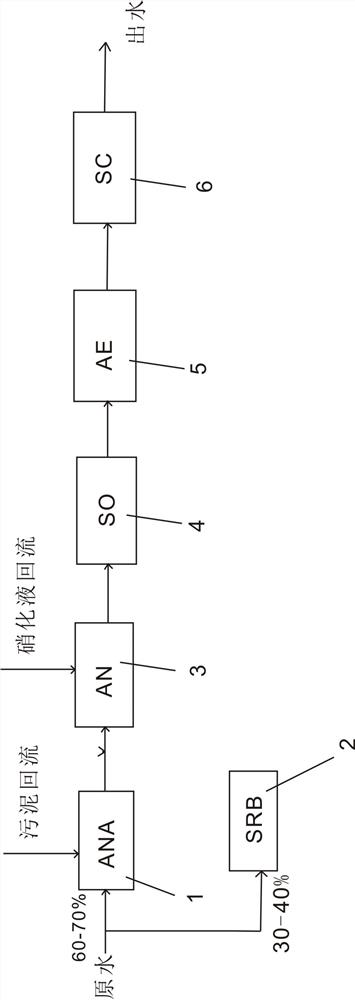

[0053] Such as figure 1 As shown, a mixed-trophic denitrification method based on sulfur reduction and sulfur autotrophic denitrification, the method includes the following steps:

[0054] Step 1: dividing the raw wastewater containing sulfate into part A and part B, wherein part A accounts for 30-40% of the total raw wastewater quality;

[0055] Step 2: Input the raw wastewater of part A into the sulfate reduction reactor (SRB pool) 2, and the raw wastewater of part A undergoes sulfate reduction reaction under the action of SRB bacteria, and SO 4 2- is reduced to S 2 o 3 2- , S 2- and total soluble sulfides such as S, lesser part is reduced to H 2 S is removed;

[0056] To facilitate solving SO 4 2- Under the action of SRB, it is reduced to TDS to exert the greatest effect. The structural design of the SRB pool 2 sampling anaerobic reaction in this embodiment, the pool body is closed and air is relatively isolated, and the anaerobic sludge is cultivated in the pool....

Embodiment 2

[0071] Except that the technical scheme of "inputting part A of the raw wastewater into the sulfate reduction reactor (SRB pool) 2 through the anaerobic tank (ANA) 1" in step 2 is different from the first embodiment, other technical solutions are the same as the first embodiment.

Embodiment 3

[0072] Embodiment three (the present invention's method handles the comprehensive wastewater application embodiment of a park, based on embodiment two)

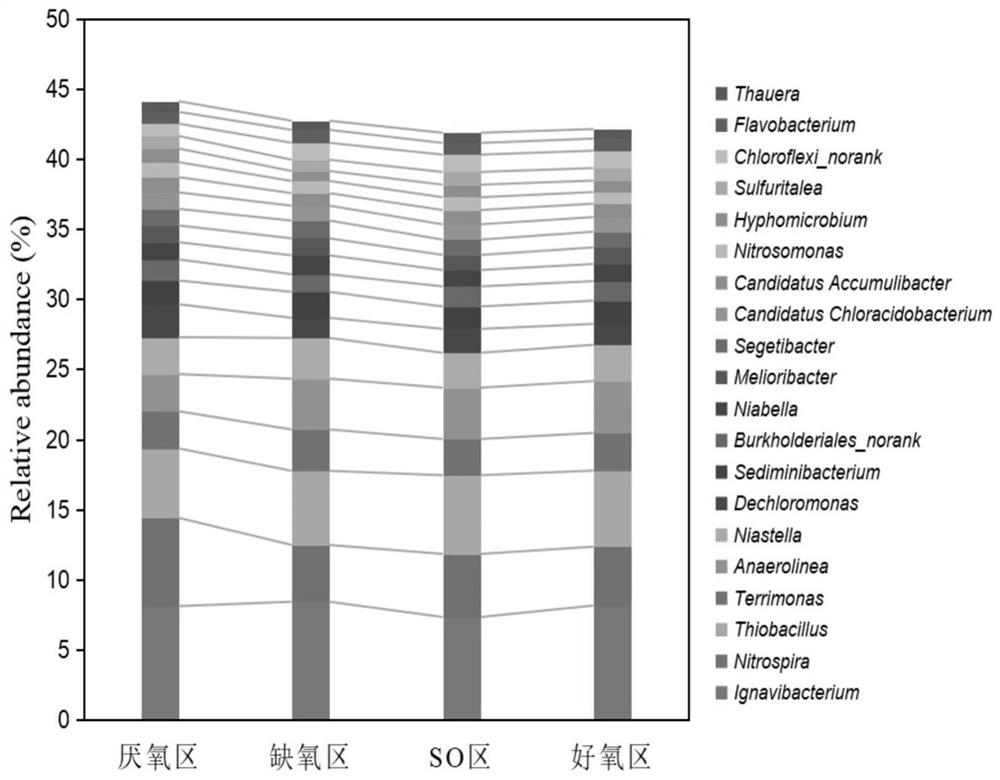

[0073] This implementation plan uses the raw water of a sewage treatment plant in an industrial park that is actually in operation as the test object, and constructs a set of 30 tons / day pilot plant for implementation.

[0074] Raw water quality: the average concentration of COD is 333mg / L, the average concentration of BOD is 116.5mg / L, the average B / C ratio is 0.35, the average concentration of total nitrogen is 46.3mg / L, the average BOD / TN of raw wastewater is 2.5, of which SO 4 2- The average concentration is 372.3mg / L, which belongs to typical low-carbon sulfur-containing wastewater, and BOD / TN cannot meet the requirements of heterotrophic denitrification.

[0075] The influent water of the pilot test device is taken from the grit chamber of a sewage treatment plant in an industrial park, and after removing large suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com