Preparation method of aluminum oxide vacuum tube with anti-flashover coating

An anti-flashover and aluminum oxide technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problems of high comprehensive cost, low coating bonding strength, small coating thickness, etc., and achieve comprehensive The effect of cost reduction, green body processing saving, and less preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

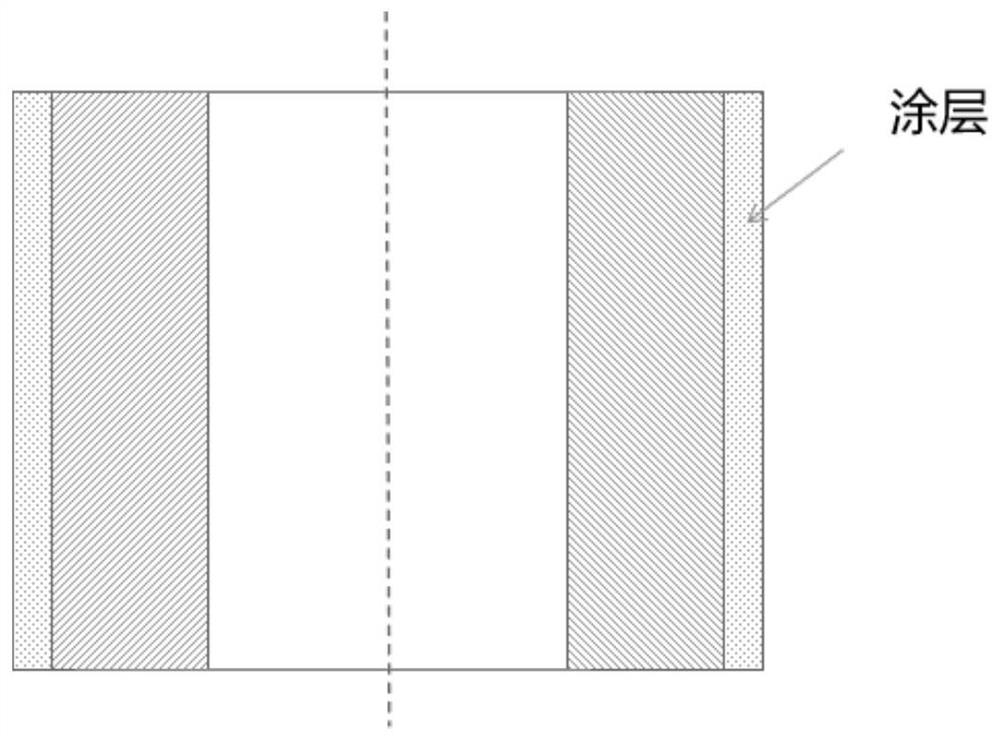

[0022] Embodiment 1: prepare as figure 1 Shown, a kind of preparation method that has anti-flashover coating aluminum oxide vacuum tube, concrete steps are as follows, the outer surface has (1~1.5) mm round aluminum oxide vacuum tube of chromium oxide coating;

[0023] Step 1. Mix 180g of monomer and 820g of deionized water to obtain a solution; among them, the monomer is methacrylamide and N, N-methylenebisacrylamide, the ratio is 15:1, and the organic matter content is 18 %The solution;

[0024] Step 2: Take 600g of the solution and add 4000g of alumina powder; take 400g of the solution and add 3000g of alumina powder;

[0025] Step 3, respectively ball milling the two solutions until there is no agglomeration to obtain slurries with viscosities of 90mPa·s and 820mPa·s;

[0026] Step 4: After filtering the two parts of slurry and defoaming in vacuum, add 23g and 17g of 2,2'-azo[2-(2-imidazolin-2-yl)propane] dihydrochloride respectively, and stir evenly;

[0027] Step 5. B...

Embodiment 2

[0033] Embodiment 2: A kind of preparation method that has anti-flashover coating alumina vacuum tube, concrete steps are as follows, prepare the circular alumina vacuum tube that inner surface has 0.5mm chromium oxide coating;

[0034] Step 1. Mix 200g of monomer and 800g of deionized water to obtain a solution; wherein, the monomer is methacrylamide and N,N-methylenebisacrylamide, the ratio is 25:1, and the organic matter content is 20 %The solution;

[0035] Step 2: Take 600g of the solution and add 4000g of alumina powder; take 400g of the solution and add 3000g of alumina powder;

[0036] Step 3, respectively ball milling the two parts of the solution until there is no agglomeration to obtain slurries with viscosities of 147mPa·s and 1059mPa·s;

[0037] Step 4: After filtering the two parts of the slurry and vacuum defoaming, add 46 g and 34 g of 2,2'-azo[2-(2-imidazolin-2-yl)propane] dihydrochloride respectively, and stir evenly;

Embodiment 3

[0043] Embodiment 3: A kind of preparation method that has anti-flashover coating aluminum oxide vacuum tube, concrete steps are as follows, prepare the round aluminum oxide vacuum tube that all have 0.5mm chromium oxide coating on inner and outer surfaces;

[0044] Step 1. Mix 220g of monomer and 780g of deionized water to obtain a solution; wherein, the monomer is methacrylamide and N,N-methylenebisacrylamide, the ratio is 30:1, and the organic matter content is 22 %The solution;

[0045] Step 2: Take 600g of the solution and add 4000g of alumina powder; take 400g of the solution and add 3000g of alumina powder;

[0046] Step 3, respectively ball milling the two solutions until no agglomeration is obtained to obtain slurries with viscosities of 194mPa·s and 1187mPa·s;

[0047]Step 4: After filtering the two parts of the slurry and vacuum defoaming, add 69 g and 51 g of 2,2'-azo[2-(2-imidazolin-2-yl)propane] dihydrochloride respectively, and stir evenly;

[0048] Step 5. Br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com