Pentazole compound material and preparation method thereof

A technology of azole compound and sodium azide, which is applied in the field of pentazole compound materials and its preparation, can solve the problems of complex non-energetic chemical ratio and density not meeting the necessary conditions, and achieve simple process, low cost, and synthetic low pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a preparation method of a pentazole compound material, comprising the following steps:

[0019] Put the sodium azide powder in the pressurization device, pressurize to 38GPa, and rotate reciprocatingly with 45° as a rotation cycle, apply shear stress, stop the rotation when the total angle of reciprocating rotation is 90°, and then carry out Laser heating to 2000K for 10 seconds yields the pentazole compound.

[0020] In the present invention, unless otherwise specified, the required preparation materials or devices are commercially available products well known to those skilled in the art.

[0021] In the present invention, the pressurizing device is preferably an unbalanced load diamond pair anvil press; the present invention has no special restrictions on the unbalanced load diamond pair anvil press, and the corresponding devices well known in the art can be used. The anvil surface of the unbalanced load diamond-anvil press is 200 μm diamond. ...

Embodiment 1

[0030] Use a diamond with an anvil surface of 200 μm to pre-press the rhenium sheet, and drill a circular hole with a diameter of 66 μm in the center of the indentation. The circular hole is used as a sample cavity for loading raw materials, and excess sodium azide powder is filled. Put it into the sample chamber, add two ruby balls with a diameter of 3 μm as the pressure standard, do not add any other medium as the pressure transmission medium, pressurize at a rate of 4GPa / min, when the pressure is increased to 38GPa, every 10s Rotate at a rate of 45°, 45° is a rotation cycle, rotate 90°, stop the rotation, and then perform laser heating to 2000K for 10 seconds to obtain a pentazole compound.

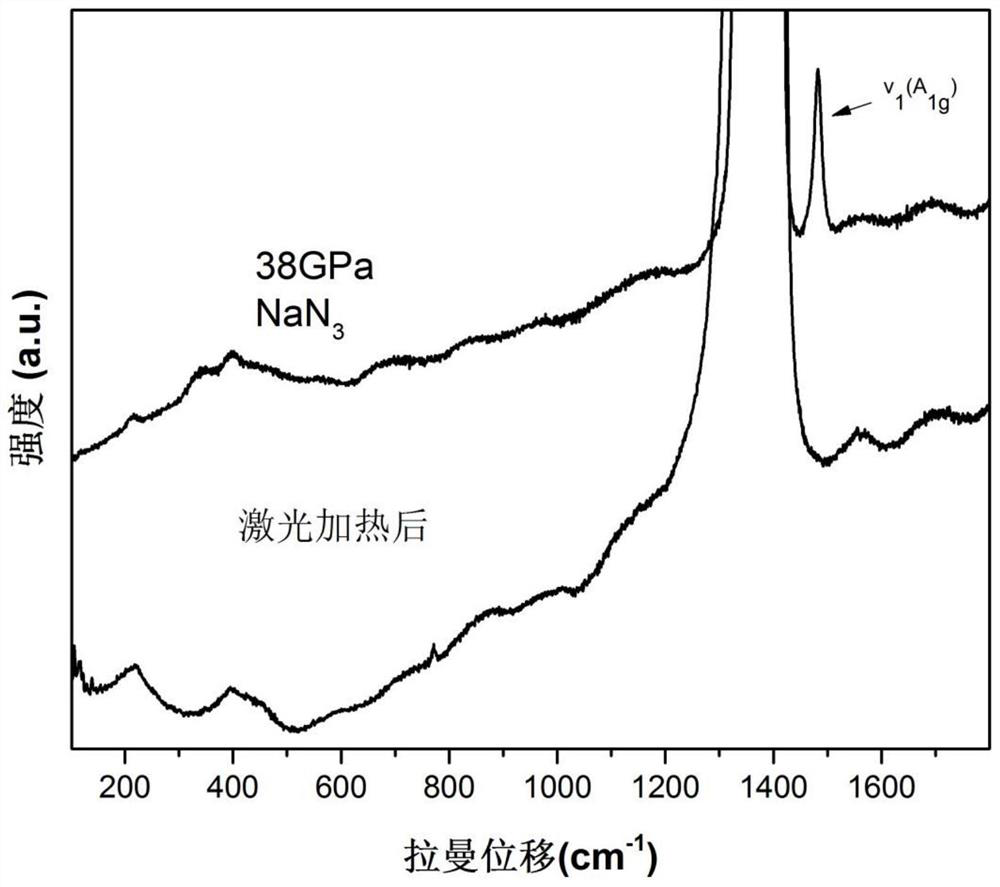

[0031] Raman scattering test is carried out to the pentazole compound material prepared in this embodiment, the results are shown in figure 1 ;Depend on figure 1 It can be seen that the stretching vibration v1 of the azide ion disappears, and the decomposition of sodium azide disapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com