Long-acting antibacterial and wear-resistant material and preparation method thereof

A wear-resistant material and long-lasting technology, applied in the field of floor tiles, can solve the problems of short-term bacteriostasis, long-term bacteriostasis, wear resistance, unsatisfactory anti-virus performance, poor wear resistance, and unsustainable antibacterial properties, etc., to achieve inhibition The effect of long time, good wear resistance and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] As a preferred embodiment, the preparation method of the wear-resistant layer is:

[0046] 1. Uniformly mix wear-resistant particles, nanomaterials, coupling agents, and antioxidants to obtain a premix;

[0047] 2. Put the adhesive and premix into the mixer, and mix at 20-70°C for 0.5-10 hours to prepare wear-resistant materials for later use.

[0048] As a preferred embodiment, in parts by weight, the raw materials for the preparation of the antibacterial layer include 1-20 parts of antibacterial agent and 30-50 parts of surfactant.

[0049] Preferably, the antibacterial agent is selected from silver-loaded antibacterial agents, zinc-loaded antibacterial agents, quaternary ammonium salt antibacterial agents, biguanide antibacterial agents, alcohol antibacterial agents, phenolic antibacterial agents, organic amine antibacterial agents, and pyridine antibacterial agents. At least one of antibacterial agents and isothiazolinone antibacterial agents.

[0050] Preferably,...

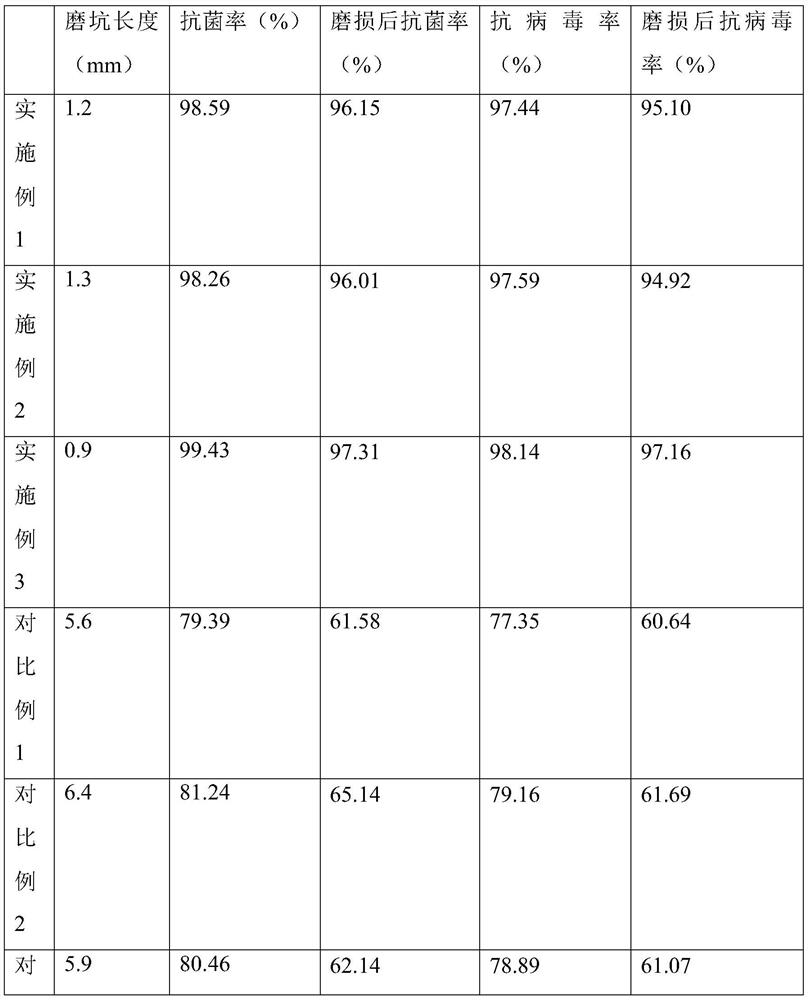

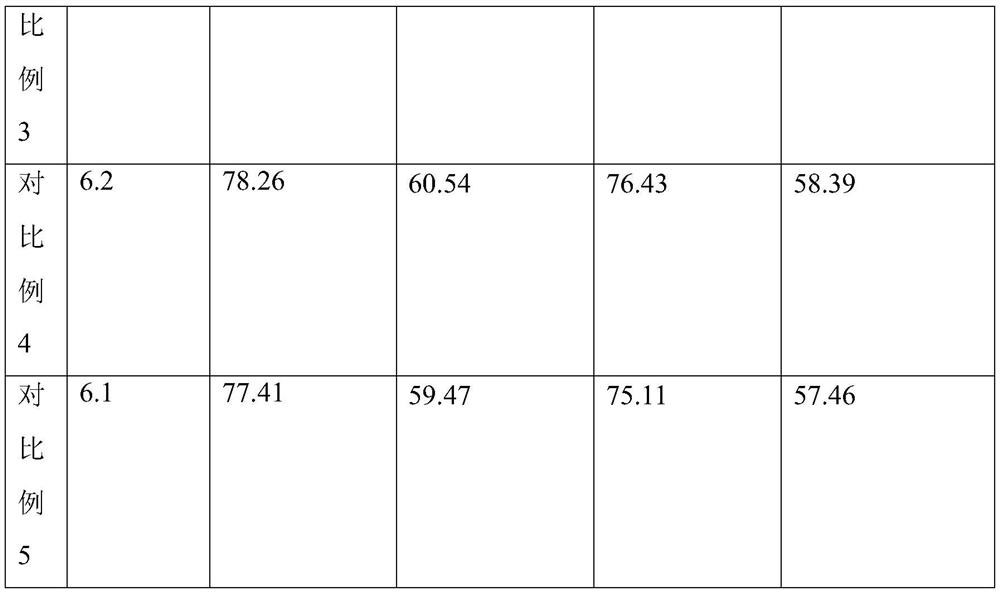

Embodiment 1

[0075] The first aspect of Embodiment 1 provides a long-acting antibacterial and wear-resistant material. The long-acting antibacterial and wear-resistant material is divided into an antibacterial layer, a wear-resistant layer, and a substrate layer sequentially from top to bottom.

[0076] In parts by weight, the raw materials for the preparation of the wear-resistant layer include 5 parts of quartz stone (with a particle size of 20 mesh), 15 parts of nanomaterials, 3 parts of polymethyl silicone resin, 0.5 parts of vinyl silane, and anti-aging agent A0. 3 copies.

[0077] The nano-material is selected from nano-nylon powder (with a particle size of 20nm) and nano-silicon dioxide (with a particle size of 15nm) at a mass ratio of 2:1.

[0078] The preparation method of the wear-resistant layer is:

[0079] 1. Evenly mix quartz stone, nanomaterials, vinyl silane, and anti-aging agent A to obtain a premix;

[0080] 2. Put the polymethylsilicone resin and the premixed material ...

Embodiment 2

[0088] Embodiment 2 The first aspect provides a long-acting antibacterial and wear-resistant material. The long-acting antibacterial and wear-resistant material is divided into an antibacterial layer, a wear-resistant layer, and a substrate layer from top to bottom.

[0089] In parts by weight, the raw materials for the preparation of the wear-resistant layer include 20 parts of quartz stone (with a particle size of 20 mesh), 50 parts of nanomaterials, 10 parts of polymethyl silicone resin, 5 parts of vinyl silane, and 6 parts of anti-aging agent .

[0090] The nano-material is selected from the compounding of nano-nylon powder (with a particle size of 20nm) and nano-silicon dioxide (with a particle size of 15nm) at a mass ratio of 6:5.

[0091] The preparation method of the wear-resistant layer is the same as in Example 1.

[0092] The raw materials for the preparation of the antibacterial layer include 20 parts of silver-loaded antibacterial agent (silver ion content is 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com