Method for preparing amorphous film with gradient structure based on high-temperature ion irradiation

An ion irradiation, amorphous thin film technology, used in ion implantation plating, final product manufacturing, sustainable manufacturing/processing, etc. The advantages of strength are weakened, and the strength of amorphous alloys is reduced, so as to achieve the effect of unique superiority, high strength and good plastic deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

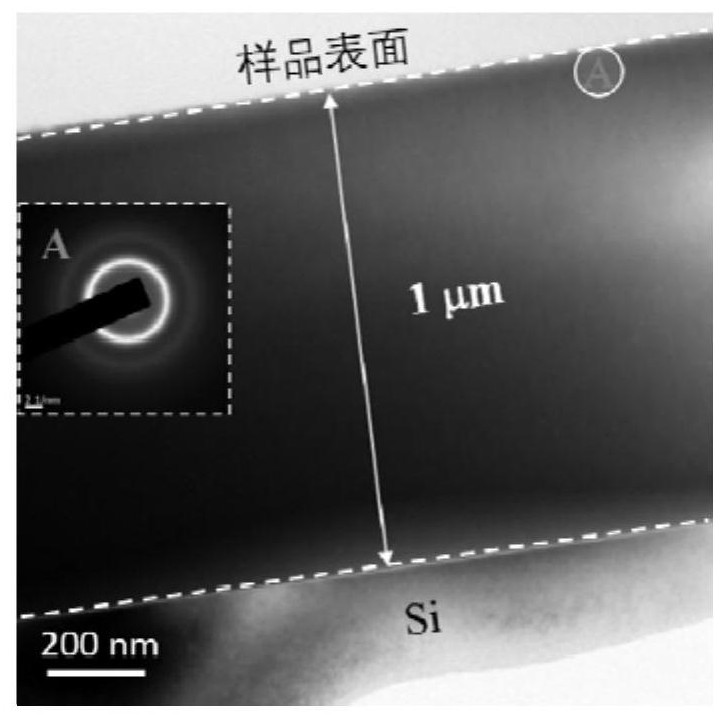

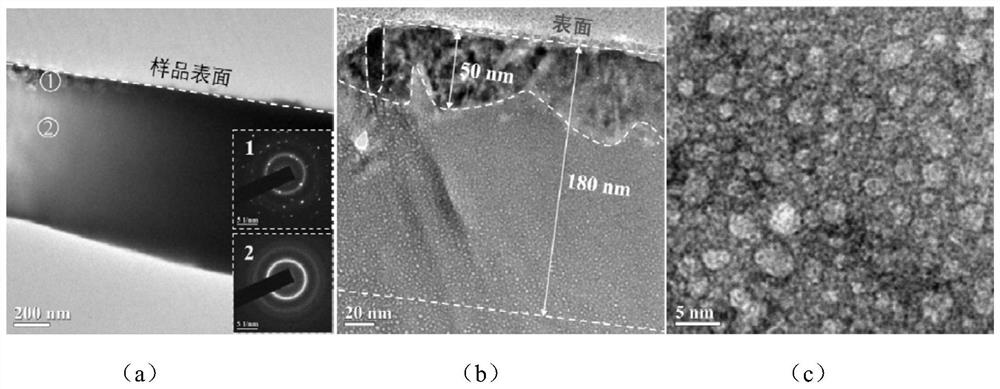

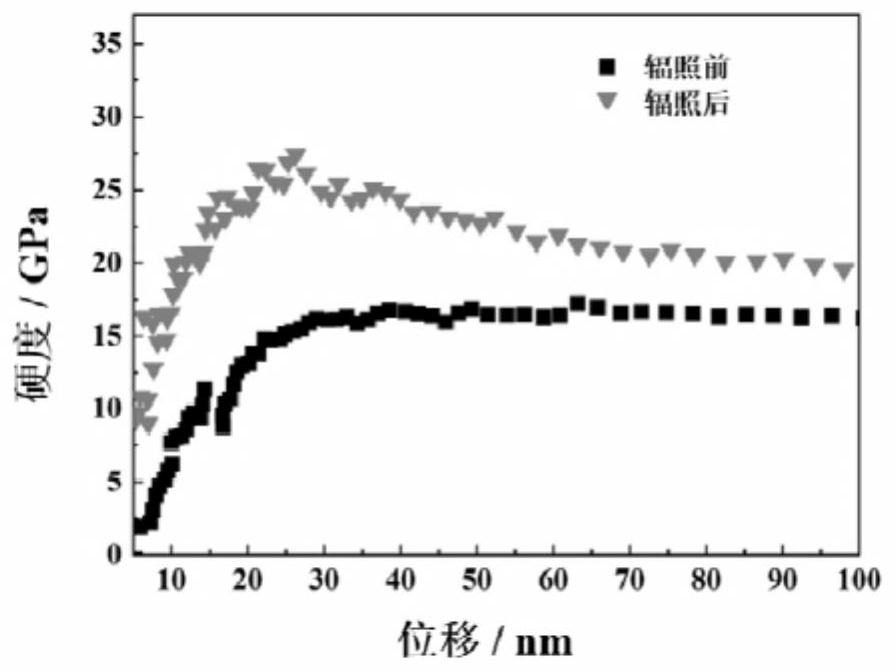

[0025] The present invention designs a method based on high temperature ion irradiation treatment for W 65 Ni 35 (at.%) A method for modifying the structure of the amorphous film to make it present a gradient structure of "hard on the surface and tough on the core". On the basis of the high-quality amorphous film prepared by magnetron sputtering, through the joint action of high temperature and ion irradiation, a large number of helium bubbles are injected into the sample, but the amorphous structure is still maintained, and obvious cracks appear on the surface. crystal phase. The samples with this gradient structure showed significantly better hardness and plastic deformation ability than the samples before irradiation. It specifically includes the following steps:

[0026] 1) The single-sided polished single crystal silicon (100) substrate is ultrasonically cleaned with acetone, alcohol and distilled water respectively, then dried by a hair dryer, placed on the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com