Micro-plasma excitation source and excitation method based on ultrasonic atomization sample introduction

A technology of micro-plasma and ultrasonic atomization, applied in the direction of plasma, material excitation analysis, electrical components, etc., can solve the problems that cannot be avoided, are not conducive to the miniaturization of analytical instruments, and are not conducive to the miniaturization of analytical instruments, so as to reduce the temperature, The effect of avoiding background interference and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

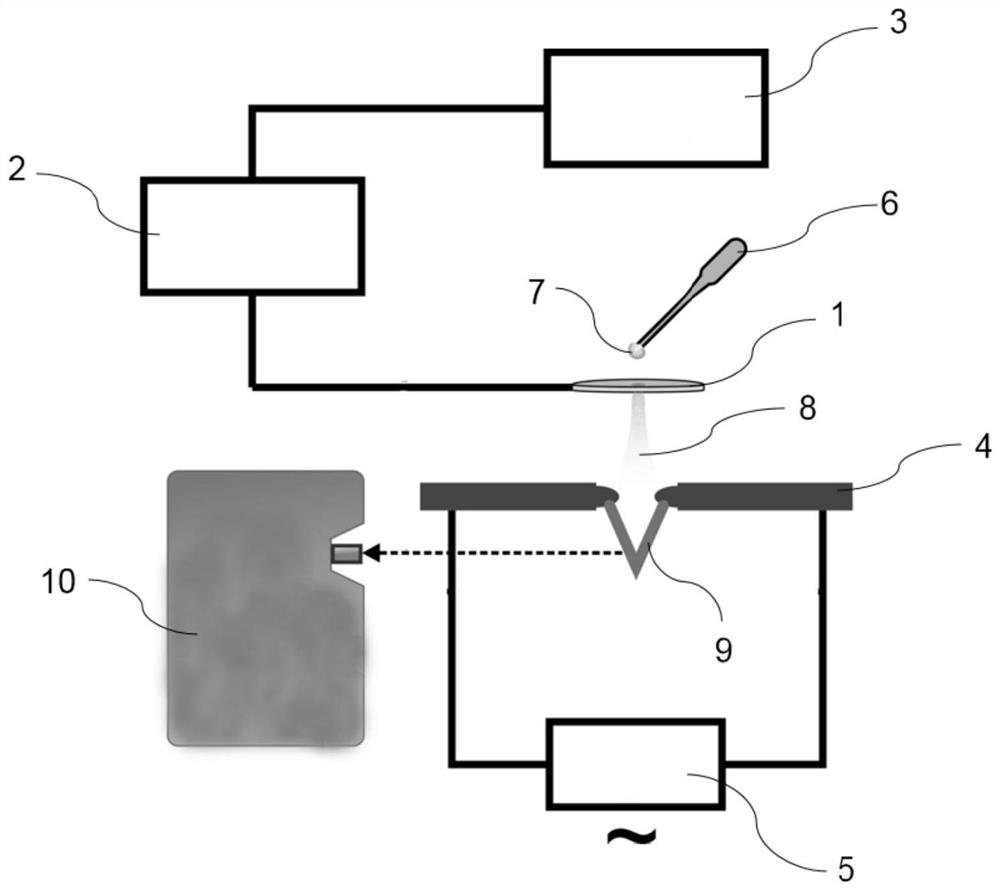

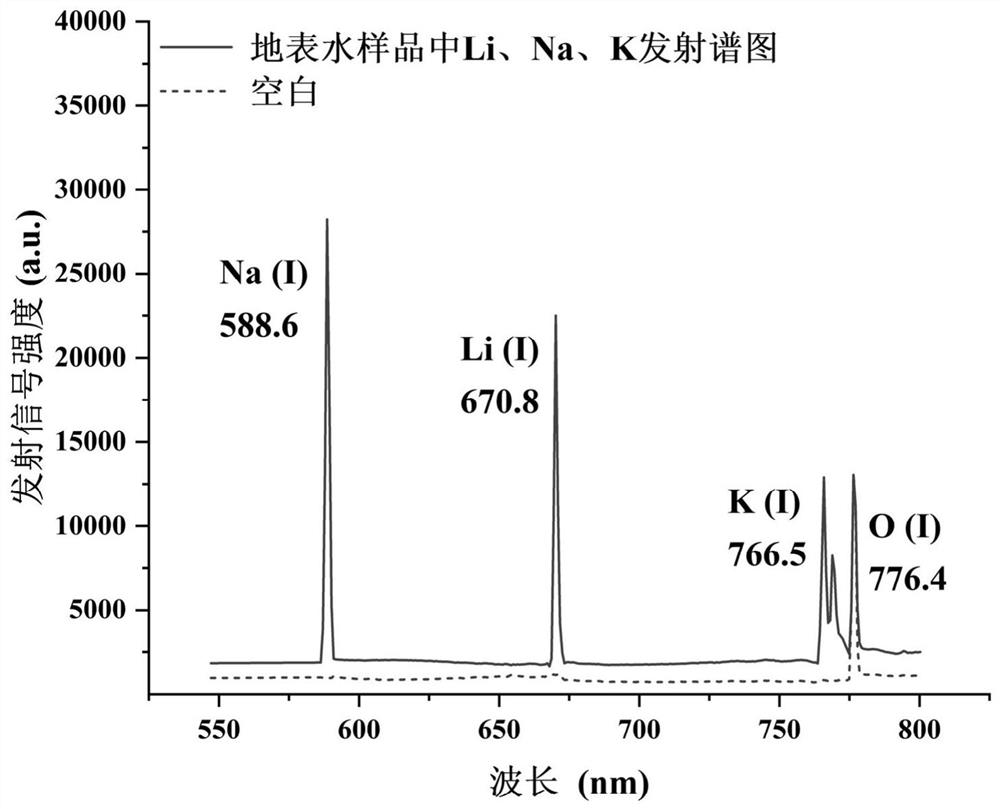

[0047] In this embodiment, an analysis method for lithium, sodium, and potassium elements in natural surface water samples is established based on the micro-plasma excitation source of ultrasonic atomization sample introduction and a micro-spectrometer, as follows:

[0048] The natural surface water sample solution is added dropwise to the central area of the ultrasonic atomization sheet 1, and the solution is converted into an aerosol 8 by cavitation and sprayed out. The aerosol 8 continuously enters the plasma excitation source, changing the path of the plasma, A V-shaped stable plasma is formed, and the heat generated by the electrode is transferred to play a role in cooling. After evaporation, dissociation, atomization, and excitation processes, lithium, sodium, and potassium elements are excited to obtain characteristic emission spectra, and the emission spectra of blank or lithium, sodium, and potassium are detected by the micro-spectrometer 9 to realize the emission in...

Embodiment 2

[0050] In this embodiment, an analysis method for lithium, sodium, and potassium elements in serum samples is established based on the combination of a micro-plasma excitation source for ultrasonic atomization sample introduction and a micro-spectrometer, as follows:

[0051] (1) Turn on the mobile power supply 3 and the AC power supply 5; (2) Add the blank solution dropwise to the central area of the ultrasonic atomizing sheet 1, and under the action of the aerosol 8, the air breakdown will automatically break down and form a stable discharge between the metal electrodes 4. V-shaped plasma; (3) After the serum sample is diluted 10-100 times with ultrapure water, it is added dropwise to the central area of the ultrasonic atomization sheet 1 and converted into an aerosol 8 and enters the plasma; (4) based on ultrasonic atomization The excitation source of the sample micro-plasma interacts with the aerosol 8 to produce the characteristic emission light of lithium, sodium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com