Antibacterial dressing and preparation method thereof

A technology of antibacterial material and antibacterial liquid, which is applied in the field of antibacterial dressing and its preparation, can solve the problems of ineffective curative effect, unsatisfactory germ killing effect, and easy inhalation of antibacterial substances by the human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

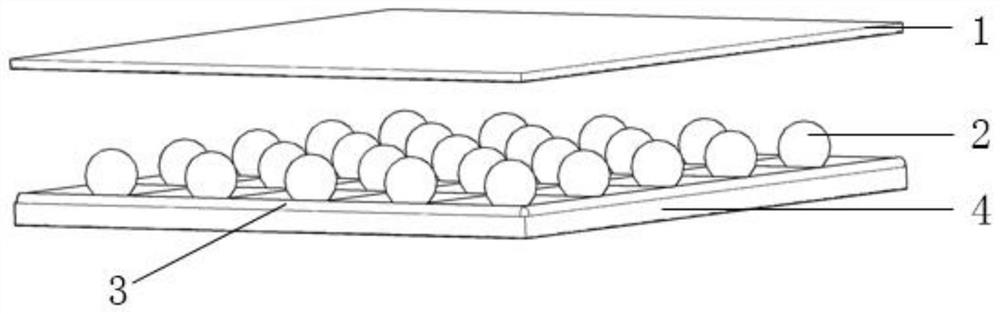

[0033] The present invention also provides the preparation method of antibacterial dressing described in above-mentioned technical scheme, comprises the following steps:

[0034] Mixing the sodium alginate solution and the antibacterial material to obtain the antibacterial sodium alginate solution;

[0035] The antibacterial sodium alginate solution is dropped into the aqueous solution containing calcium ions, and left to stand to obtain antibacterial liquid beads;

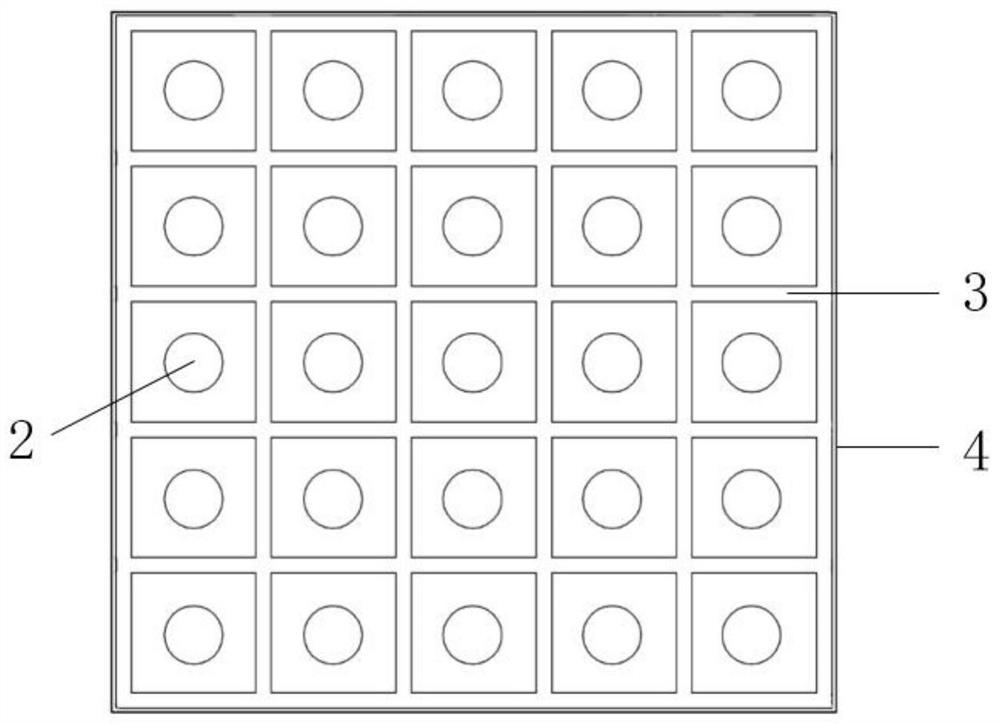

[0036] A plurality of the antibacterial liquid beads are separated and placed on the spunlace nonwoven base fabric, and then covered with the spunlace nonwoven fabric surface layer to obtain an antibacterial dressing.

[0037] The invention mixes the sodium alginate solution and the antibacterial material to obtain the antibacterial sodium alginate solution. In the present invention, the concentration of the sodium alginate solution is preferably 1-5 wt%, more preferably 3-4 wt%. In the present invention, the pr...

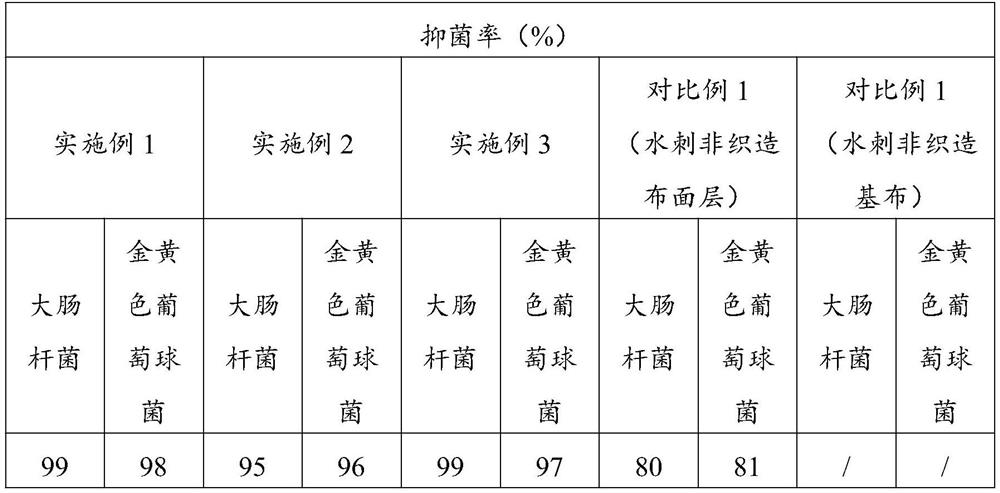

Embodiment 1

[0053] At room temperature, add sodium alginate into purified water and stir to completely dissolve the sodium alginate to obtain a 3% sodium alginate solution;

[0054] Adding nano-silver particles with a particle diameter of 50nm into the sodium alginate solution, stirring, so that the nano-silver particles are dispersed in the sodium alginate solution to obtain an antibacterial sodium alginate solution; the mass fraction of the nano-silver particles is 1%;

[0055] At room temperature, calcium chloride is added into purified water, stirred, and the calcium chloride is completely dissolved to obtain a calcium chloride solution with a mass fraction of 5%;

[0056] Use a syringe to drip the antibacterial sodium alginate solution into the calcium chloride solution, the inner diameter of the needle of the syringe is 2mm, and the dropping speed is 1 second / drop; stand for 3 minutes to react to obtain antibacterial liquid beads; the antibacterial liquid beads The diameter is 3~4mm...

Embodiment 2

[0062] At room temperature, add sodium alginate into purified water and stir to completely dissolve the sodium alginate to obtain a 3% sodium alginate solution;

[0063] Adding nano-zinc particles with a particle size of 50nm into the sodium alginate solution and stirring to disperse the nano-zinc particles in the sodium alginate solution to obtain an antibacterial sodium alginate solution; the mass fraction of the nano-zinc particles is 2%;

[0064] At room temperature, calcium chloride is added into purified water, stirred, and the calcium chloride is completely dissolved to obtain a calcium chloride solution with a mass fraction of 5%;

[0065] Use a syringe to drop the antibacterial sodium alginate solution into the calcium chloride solution, the inner diameter of the needle of the syringe is 1mm, and the dropping speed is 0.6 seconds / drop; stand for 3min to obtain antibacterial liquid beads; the antibacterial liquid beads The diameter is 1.5~2mm;

[0066] On the spunlace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com