Environmental complex response homogeneous expansion type self-repairing microcapsule for concrete, and preparation method thereof

A self-healing microcapsule and expansion technology, applied in the field of materials, can solve the problems of low compatibility between organic repair products and the matrix, difficulty in large-scale production and application, and inability to guarantee microcapsules, etc., to achieve good matching of mechanical properties , low price, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

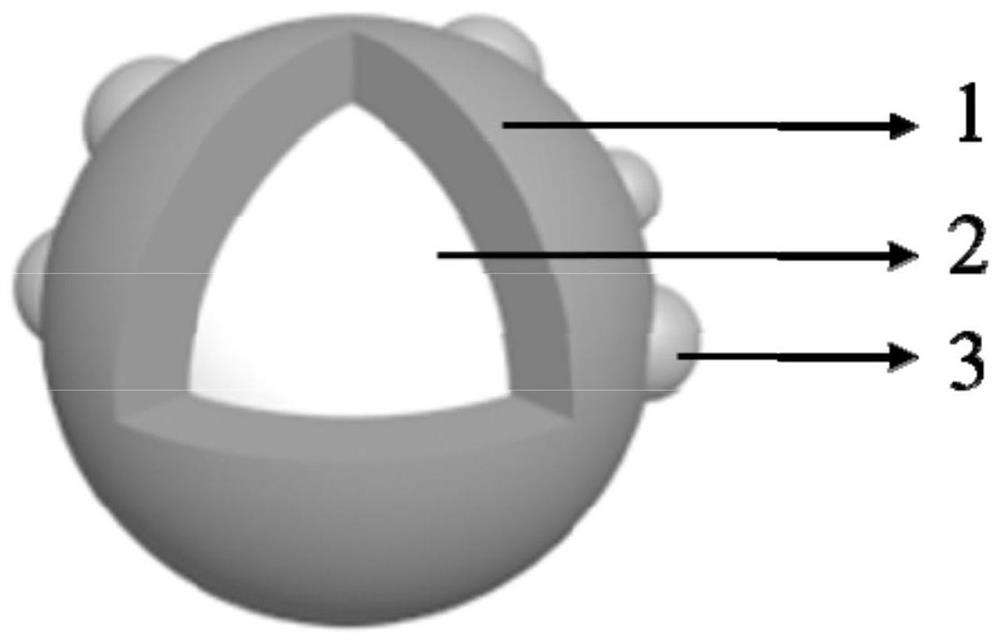

Image

Examples

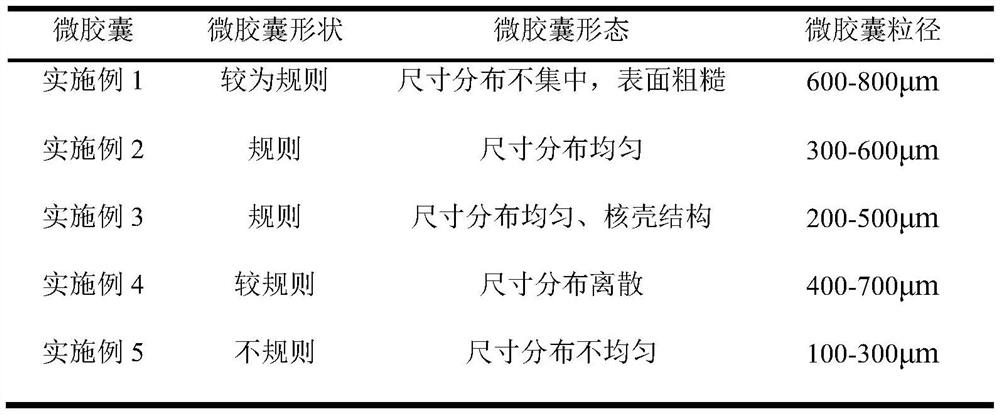

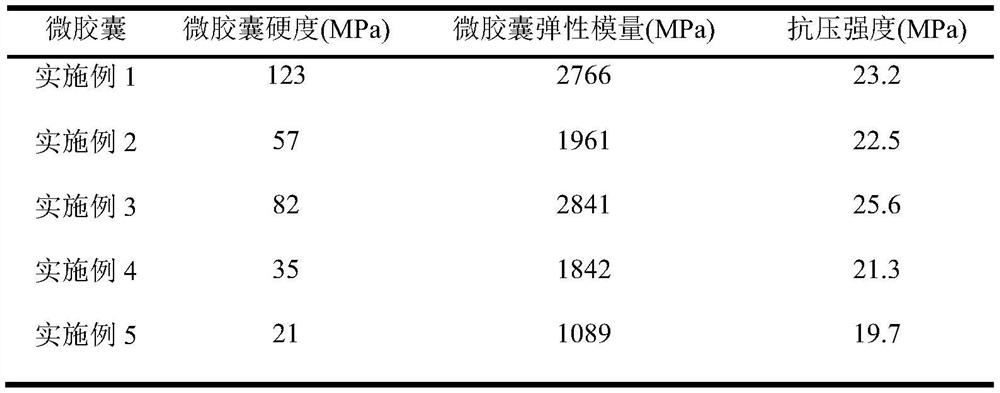

Embodiment 1

[0031] Inorganic core material self-healing microcapsules for concrete, including core material and wall material covering the core material. The core material is composed of 85 parts of bentonite restoration agent, 25 parts of clay curing agent, 25 parts of MgO expansion agent and 3 parts of adhesive in parts by weight. Described wall material is counted in parts by weight, and described bentonite restoration agent is made up of 70% silicon dioxide, 20% aluminum oxide and 10% water, and clay solidifying agent is made up of 10% silicon dioxide, 30% calcium oxide, 20% % calcium aluminate, 50% potassium aluminum sulfate, 55% cement and 50% clay, composed of 0.5 parts of chloride ion trigger and 3 parts of capsule wall material, the capsule wall material is ethyl cellulose. Wherein, the binder is microcrystalline cellulose. The chloride ion trigger is cuprous chloride; the particle size of the chloride ion trigger is 0.01-100 μm.

[0032] The preparation method of the self-repa...

Embodiment 2

[0036] Embodiment 2: Different from Embodiment 1,

[0037] Inorganic core material self-healing microcapsules for concrete, including core material and wall material covering the core material. The core material is composed of 100 parts of bentonite restoration agent, 10 parts of clay curing agent, 35 parts of MgO expansion agent and 6 parts of binder in parts by weight; the bentonite restoration agent consists of 60% silicon dioxide, 32% Composed of aluminum oxide and 8% water, the clay curing agent is composed of 20% silicon dioxide, 25% calcium oxide, 40% calcium aluminate, 30% potassium aluminum sulfate, 20% cement and 40% clay. The wall material consists of 1 part of chloride ion trigger and 6 parts of capsule wall material in parts by weight, and the capsule wall material is ethyl cellulose. Wherein, the binder is microcrystalline cellulose. The chloride ion trigger is silver chloride.

[0038] The preparation method of the self-repairing microcapsules of inorganic co...

Embodiment 3

[0042] Embodiment 3: Different from Embodiment 1,

[0043] Inorganic core material self-healing microcapsules for concrete, including core material and wall material covering the core material. Described core material is made up of 90 parts of bentonite restorative agents, 20 parts of clay curing agents, 30 parts of MgO expansion agents and 4 parts of binders in parts by weight; Composed of aluminum oxide and 6% water, the clay curing agent is composed of 30% silicon dioxide, 20% calcium oxide, 35% calcium aluminate, 40% potassium aluminum sulfate, 60% cement and 45% clay. The wall material consists of 0.7 parts of chloride ion trigger and 4 parts of capsule wall material in parts by weight, and the capsule wall material is polyvinyl alcohol. Wherein, the adhesive is composed of 2 parts of Tween 80 and 2 parts of hydroxypropyl methylcellulose. Described chloride ion trigger is lead sulfate.

[0044] The preparation method of the self-repairing microcapsules of inorganic cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com