Space-time uniform distribution system for a tank liquid temperature field of an anode film-making tank and regulation and control method of space-time uniform distribution system

A technology with uniform distribution and temperature field, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc. The problems of large differences in type structure and inconsistent deposition efficiency can achieve the effect of promoting uniform distribution of space and time, shortening heating time, and improving film uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

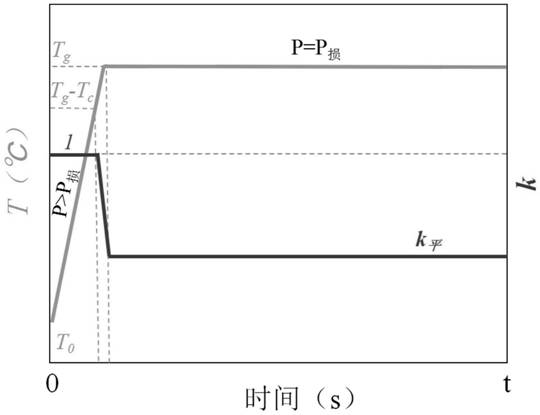

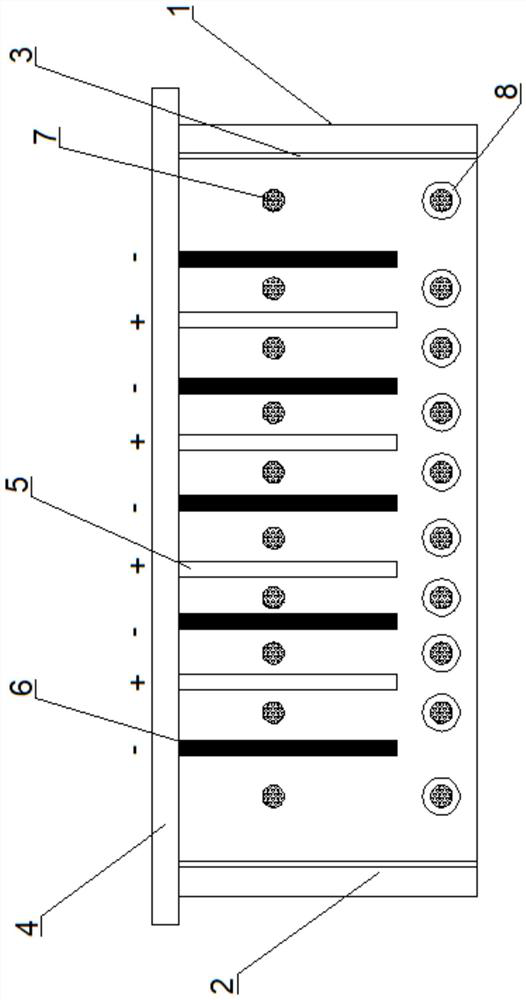

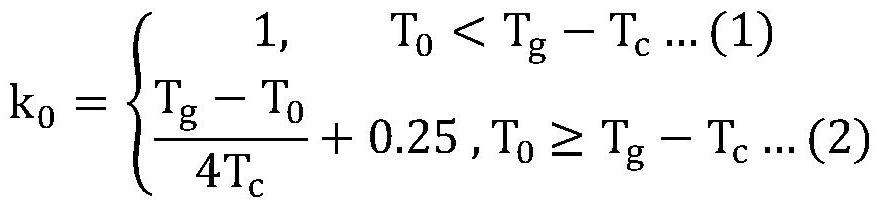

[0034] Such as figure 1 As shown, this embodiment provides a system for evenly distributing the temperature field of the anode film-making tank in time and space. Cover 4, a plurality of anode plates 5 and cathode plates 6 are arranged inside the film-making tank, the anode plates 5 and cathode plates 6 are alternately arranged at equal intervals, and a plurality of heating and temperature control units are arranged on the film-making tank, so The heating and temperature control units are arranged in parallel between the anode plate 5 and the cathode plate 6, and the multiple heating and temperature control units are independently controlled without interfering with each other, and power heating is adapted according to the requirements of different temperature control areas.

[0035]The heating and temperature control unit includes a heating tube 8, the heating tube 8 is installed on the bottom inner wall of the film-making tank, a temperature sensor 7 is arranged above the he...

Embodiment 2

[0044] The difference between this embodiment and Example 1 is that: the film-making tank is equipped with film-making liquid, and the cation in the film-making liquid is Mn 2+ 、Co 2+ , the anion is NO 3 - .

[0045] The molar concentration of cations in the membrane-forming solution is 1 mol / L, and the molar concentration of anions is 0.5 mol / L.

[0046] The anode plate is a binary alloy composed of Pb and Ag; the cathode plate is graphite.

Embodiment 3

[0048] The difference between this embodiment and Example 2 is that: the film-making tank is equipped with film-making liquid, and the cation in the film-making liquid is Mn 2+ , the anion is NO 3 - .

[0049] The molar concentration of cations in the membrane-making solution is 2mol / L, and the molar concentration of anions is 1mol / L;

[0050] The anode plate is a ternary alloy composed of Pb, Ag and Sb; the cathode plate is copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com