Semiconductor structure and forming method thereof

A semiconductor and graphics technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of photoresist not being uniformly exposed, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] At present, the reliability of graphics transmission still needs to be improved. Combining with a method of forming a semiconductor structure, the reason why its performance needs to be improved is analyzed.

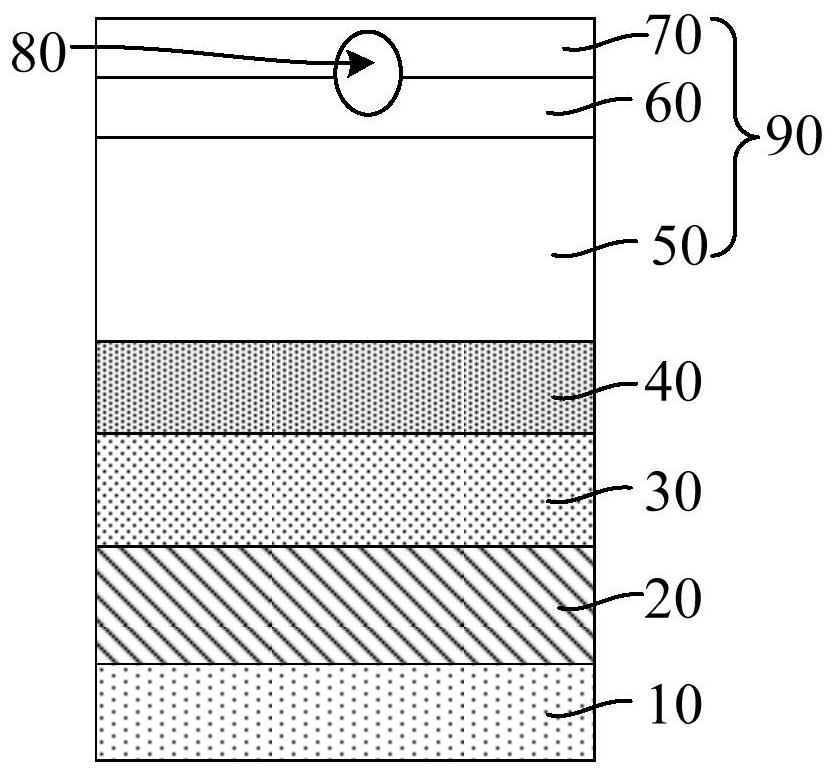

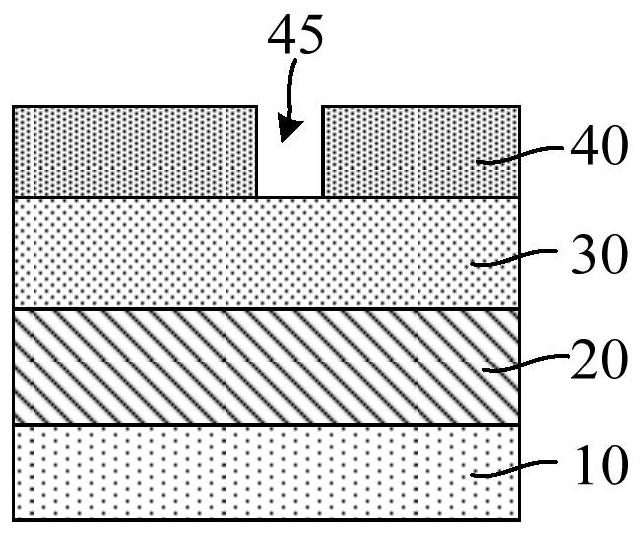

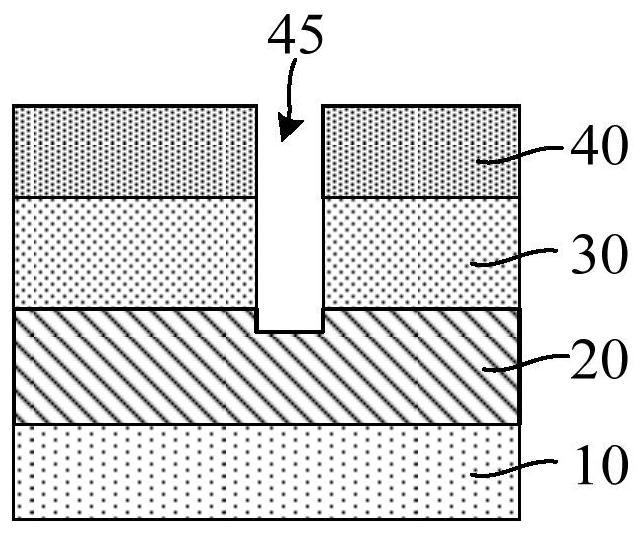

[0014] Figure 1 to Figure 5 It is a structural schematic diagram corresponding to each step in a method for forming a semiconductor structure.

[0015] refer to figure 1 , providing a substrate (not shown), on which the interlayer dielectric layer 10 is formed. The interlayer dielectric layer 10 is used to form interconnection holes.

[0016] continue to refer figure 1 , forming a metal hard mask layer 20 on the interlayer dielectric layer 10 ; forming a buffer oxide layer 30 on the metal hard mask layer 20 ; and forming a pattern transfer material layer 40 on the buffer oxide layer 30 .

[0017] As an example, the material of the graphic transfer material layer 40 is amorphous silicon (a-Si).

[0018] continue to refer figure 1 , forming a mask stack 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com