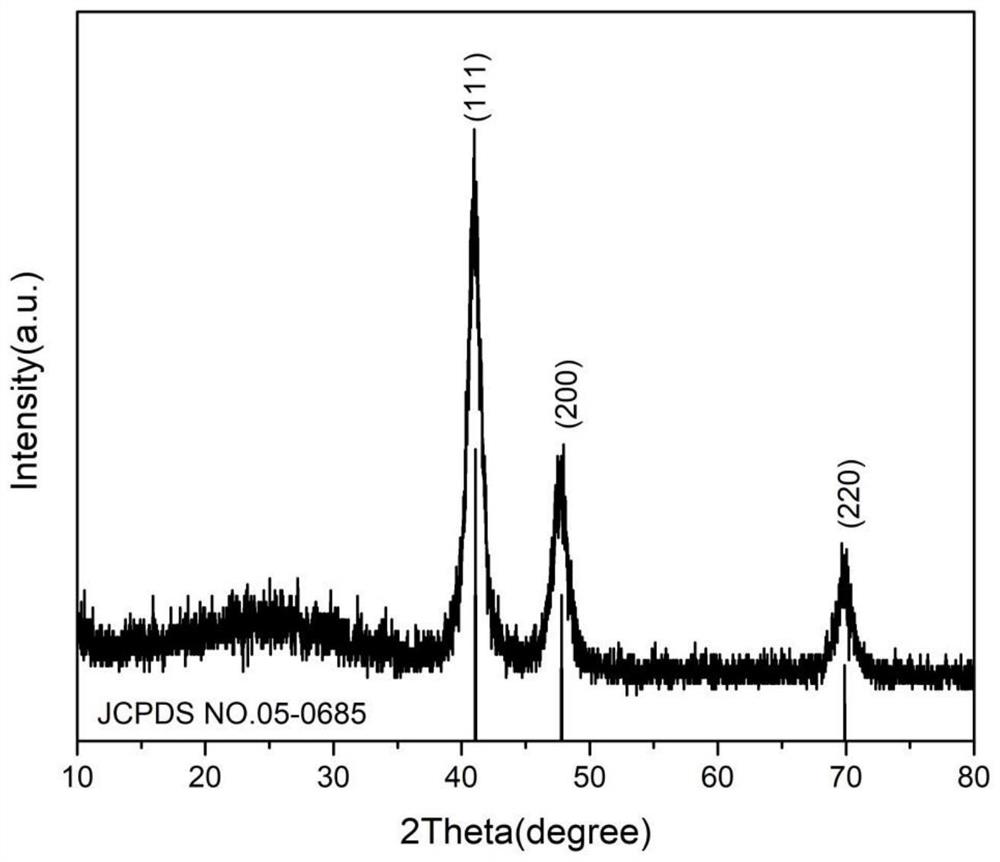

Preparation method and application of rhodium-based electro-catalytic material

An electrocatalytic material, rhodium-based technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of poor catalytic performance, easy agglomeration, weakened electrocatalytic effect of rhodium-based hydrogen evolution electrocatalytic material, etc. The effect of catalytic hydrogen evolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

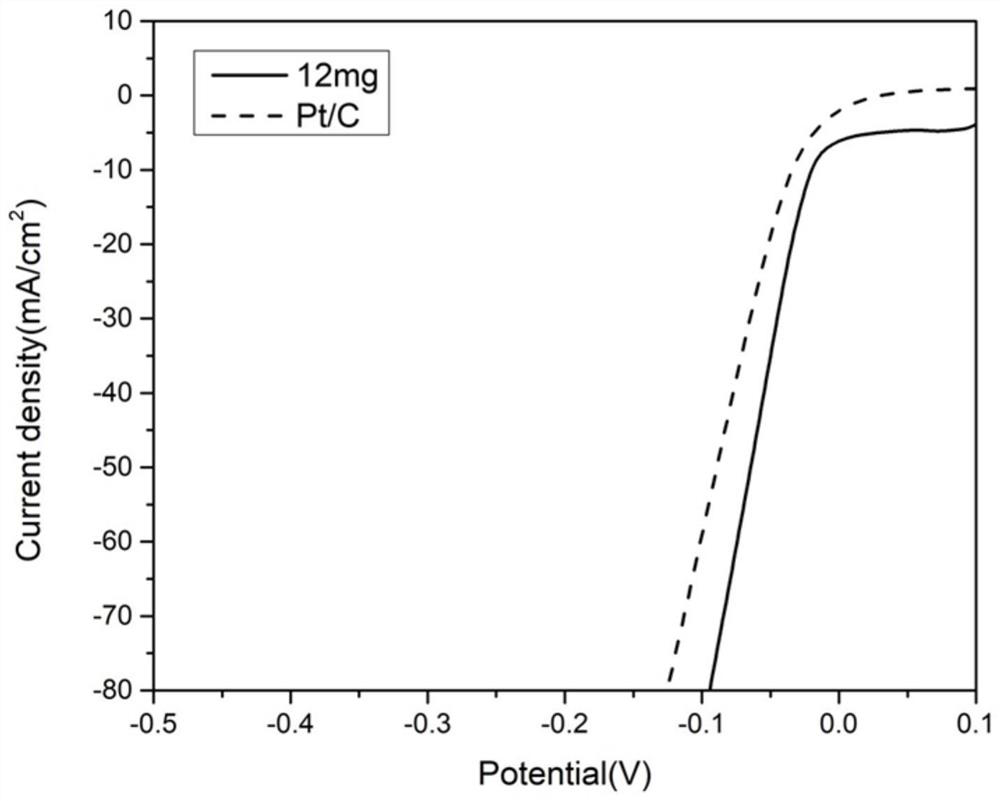

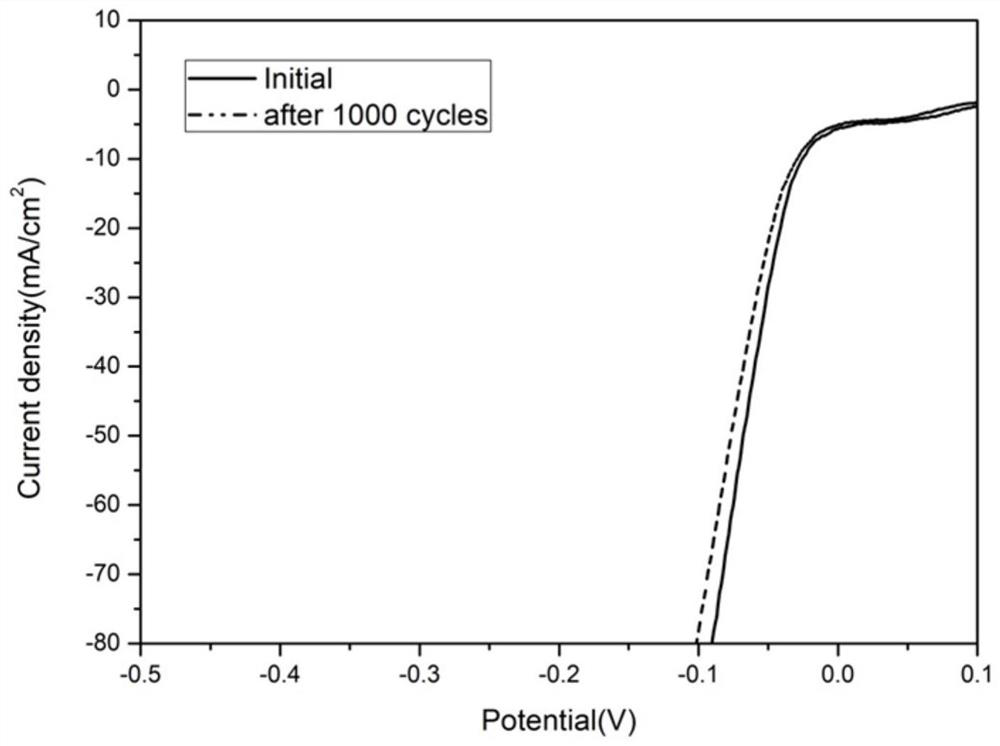

Embodiment 1

[0032] (1) In a 250ml beaker A, put a stirring bar, then add 0.2g melamine, and 12mg rhodium trichloride, after adding 80ml distilled water, put the beaker A on a magnetic stirrer for 1 hour. In a 100ml beaker B, add 0.2g cyanuric acid, then add 80ml distilled water, and ultrasonically dissolve it for 30 minutes.

[0033] (2) Pour the dissolved cyanuric acid solution, namely beaker B, into the melamine solution dissolved with rhodium trichloride, namely beaker A, and continue stirring for 1 hour at room temperature to obtain a mixed solution.

[0034] (3) The mixed solution was then placed in a 200ml reaction kettle, kept at 180° C. for 6 hours, and cooled to room temperature to obtain a reacted mixed solution.

[0035] (4) Then, the mixed solution in (3) is suction-filtered and then dried, and the drying condition is 80° C. for 12 hours to obtain a self-assembly precursor.

[0036] (5) Transfer the self-assembled precursor to a quartz boat, cover it and place it in a tube fu...

Embodiment 2

[0038] (1) In a 250ml beaker A, put a stirring bar, then add 0.2g melamine, and 2mg rhodium trichloride, after adding 80ml distilled water, put the beaker A on a magnetic stirrer for 1 hour. In a 100ml beaker B, add 0.2g cyanuric acid, then add 80ml distilled water, and ultrasonically dissolve it for 30 minutes.

[0039] (2) Pour the dissolved cyanuric acid solution, namely beaker B, into the melamine solution dissolved with rhodium trichloride, namely beaker A, and continue stirring for 1 hour at room temperature to obtain a mixed solution.

[0040] (3) The mixed solution was then placed in a 200ml reaction kettle, kept at 180° C. for 6 hours, and cooled to room temperature to obtain a reacted mixed solution.

[0041] (4) Then, the mixed solution in (3) is suction-filtered and then dried, and the drying condition is 80° C. for 12 hours to obtain a self-assembly precursor.

[0042] (5) Transfer the self-assembled precursor to a quartz boat, cover it and place it in a tube fur...

Embodiment 3

[0044] (1) In a 250ml beaker A, put a stirring bar, then add 0.2g melamine and 6mg rhodium trichloride, after adding 80ml distilled water, put the beaker A on a magnetic stirrer for 1 hour. In a 100ml beaker B, add 0.2g cyanuric acid, then add 80ml distilled water, and ultrasonically dissolve it for 30 minutes.

[0045](2) Pour the dissolved cyanuric acid solution, namely beaker B, into the melamine solution dissolved with rhodium trichloride, namely beaker A, and continue stirring for 1 hour at room temperature to obtain a mixed solution.

[0046] (3) The mixed solution was then placed in a 200ml reaction kettle, kept at 180° C. for 6 hours, and cooled to room temperature to obtain a reacted mixed solution.

[0047] (4) Then, the mixed solution in (3) is suction-filtered and then dried, and the drying condition is 80° C. for 12 hours to obtain a self-assembly precursor.

[0048] (5) Transfer the self-assembled precursor to a quartz boat, cover it and place it in a tube furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com