Preparation method of low-sodium salt

A low-sodium salt and potassium rock salt technology is applied in the preparation of low-sodium salt, and in the field of preparing low-sodium salt by mixing halogen-crystallization, which can solve the problems of uncontrollable particle size of low-sodium salt products and relatively strict temperature requirements. , to achieve the effect of low cost, controllable particle size and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

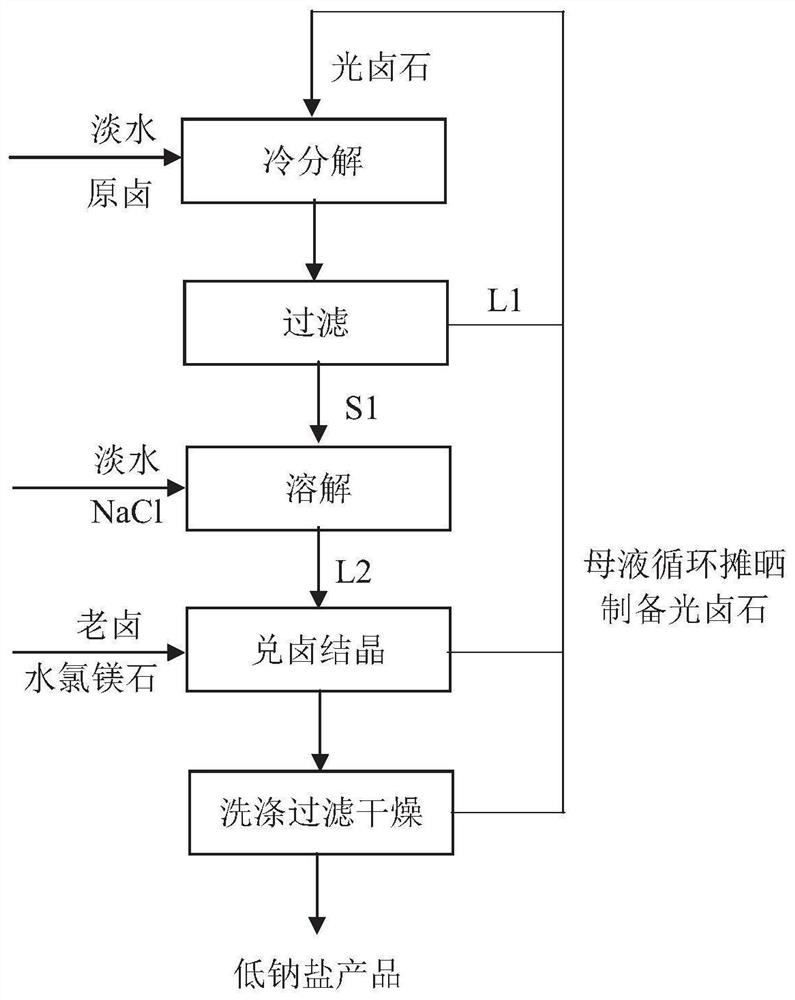

[0023] Concretely, as an aspect of the technical solution of the present invention, the preparation method of a kind of low sodium salt that it relates to comprises:

[0024] Decomposing carnallite to obtain the first mother liquor and potassium halite solid;

[0025] mixing the potassium halite solid with fresh water to form a second mother liquor;

[0026] And, the second mother liquor and the magnesium source are mixed for reaction and crystallization to obtain low-sodium salt.

[0027] In some preferred embodiments, the preparation method specifically includes: mixing carnallite with fresh water for decomposition and filtration to obtain the first mother liquor and potassium halite solid, wherein the mass ratio of carnallite to fresh water is 1 : 0.9~1.2.

[0028] In some preferred embodiments, the chemical composition of the carnallite includes: K + 7.0~12.2wt%, Mg 2+ 6.9~8.6wt%, Cl - 36.0~46.2wt%, Na + 0~12.8wt%, H 2 O 27.1~43.3wt%.

[0029] And / or, recovering th...

Embodiment 1

[0051] Decompose and filter carnallite with fresh water to obtain mother liquor L1 and potassium halite solid S1;

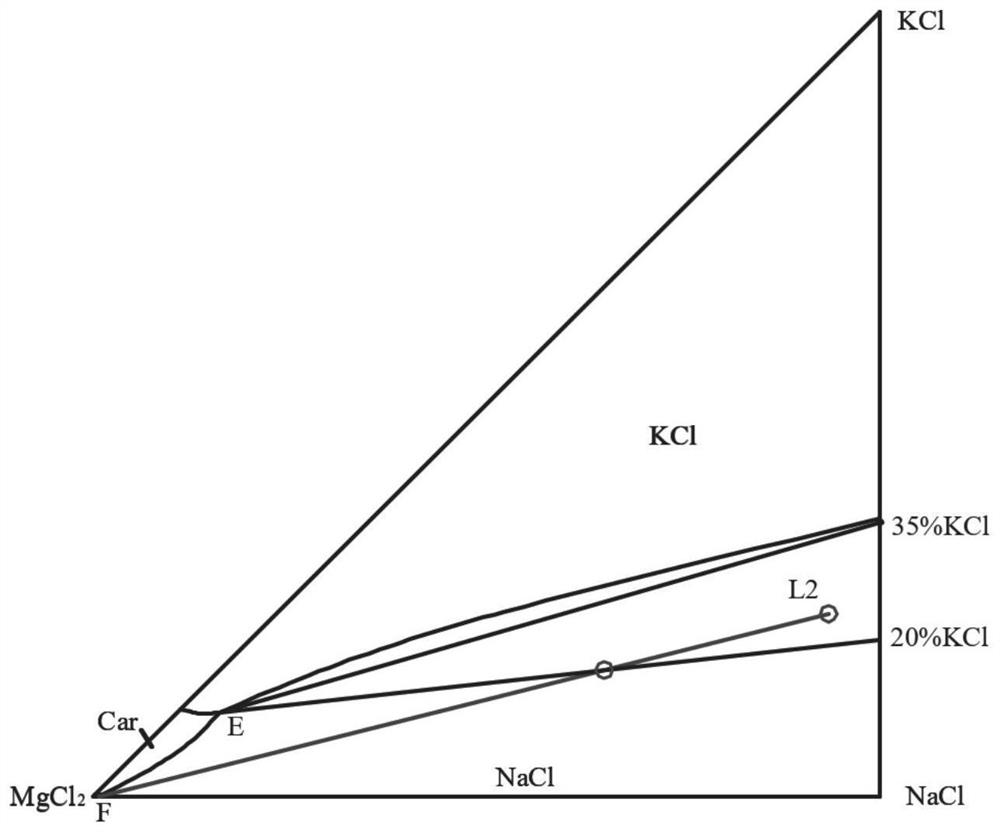

[0052] Dissolve solid S1 and fresh water at a mass ratio of 1:2.2 to obtain mother liquor L2, wherein the chemical composition of S1 is: Na + 7.30wt%, K + 5.91wt%, Mg 2+ 0.56wt%, Cl - 17.99wt%; add in 15L crystallizer figure 2 Middle E point mother liquor (the chemical composition of E point mother liquor is: Na + 0.6~0.8wt%, K + 1.6~1.8wt%, Mg 2+ 5.9~6.6wt%, Cl - 21.4~22.3wt%, H 2 O 68.5~69.8wt%) is base liquid 15L, get 5.20kg L2, 5.90kg old bittern (Na + 0.33wt%, K + 0.03wt%, Mg 2+ 8.34wt%, C1-24.85wt%), while adding to the crystallizer at one time, after 30 minutes of reaction, it was filtered to obtain a low-sodium salt product with a KCl content of 22.88wt%. After sieving, its particle size distribution d>180 μm was 9.02 %, 7.21% for 150 μm<d<180 μm, and 82.1% for 125 μm<d<150 μm.

Embodiment 2

[0054] Decompose and filter carnallite with fresh water to obtain mother liquor L1 and potassium halite solid S1;

[0055] Dissolve solid S1 and fresh water at a mass ratio of 1:2.6 to obtain mother liquor L2, wherein the chemical composition of S1 is: Na + 8.00wt%, K + 5.78wt%, Mg 2+ 0.51wt%, Cl - 19.12wt%; add in 15L crystallizer figure 1 The mother liquid at point E in the center is 15L of base liquid. Take 8.90kg of L2 and 9.81kg of old brine respectively at the same time, adopt the two-way dropping method, feed time 1h, control the feeding speed with a peristaltic pump, add to the crystallizer, and filter after 30min of reaction. A low-sodium salt product with a KCl content of 26.81 wt% was obtained. After sieving, the particle size distribution of d>180 μm was 74.36 wt%, 150 μm<d<180 μm was 3.59 wt%, and 125 μm<d<150 μm was 7.76 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com