Preparation method and application of regenerated cement based on high temperature and carbonization coupling

A technology of recycled cement and high-temperature carbonization, which is applied in the direction of cement production, etc., can solve the problems of poor performance of recycled cement that cannot completely replace ordinary cement, high temperature, and existing environment, so as to achieve the effect of carbon sequestration, improve the application effect, and the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

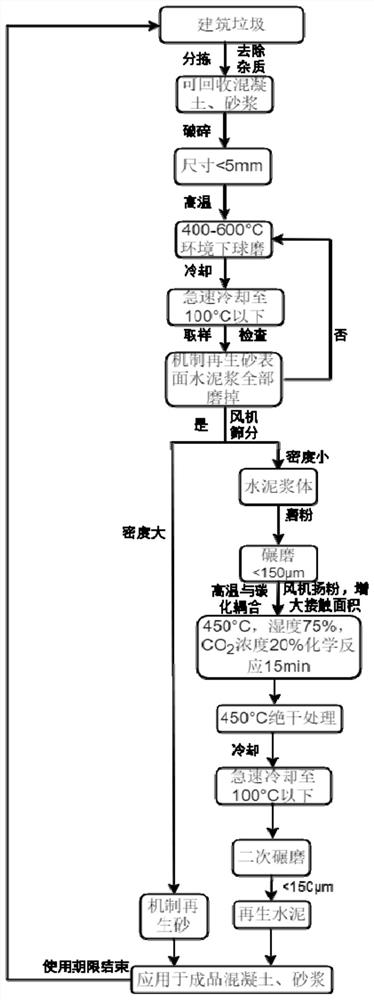

[0031] The invention provides a method for preparing recycled cement based on the coupling of high temperature and carbonization, including: grinding the cement slurry, coupling high temperature and carbonization treatment, drying treatment, rapid cooling, and secondary grinding to prepare recycled cement . Wherein, the cement paste is a pure cement paste block, or the cement paste is prepared by sorting and crushing construction waste, separating mortar, and fan screening. The recycled cement prepared by the present invention can be applied to the preparation of finished concrete or finished mortar by adding admixtures.

[0032] figure 1 Schematically shows the process for the preparation and application of recycled cement based on the coupling of high temperature and carbonization in an embodiment of the present invention. In this embodiment, the cement slurry is prepared by sorting and ball milling with construction waste as raw material It is also a method of re-extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com