Pigment derivative, preparation method thereof, pigment composition containing pigment derivative and application of pigment composition

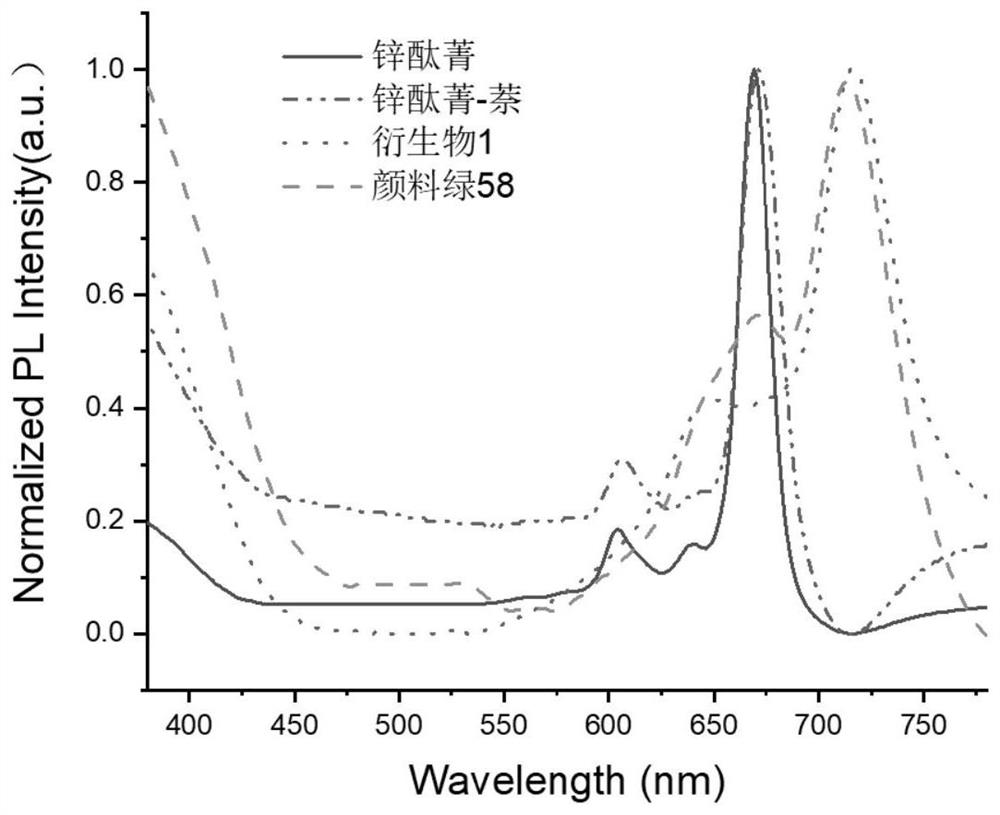

A pigment derivative and rigid technology, applied in pigment paste, chemical instruments and methods, azo dyes, etc., can solve the problems of limited pigment particle size control ability, poor heat resistance of phthalocyanine pigment derivatives, and difficult to unite , to achieve excellent transparency, narrow particle size distribution, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the pigment derivative is to firstly prepare an intermediate product containing a Q-Ar substituent group, and then halogenate the intermediate product to obtain the pigment derivative.

[0044] Wherein, the preparation method of the intermediate product containing the Q-Ar substituent group can be prepared under the action of a catalyst by phthalic anhydride substituted by rigid unit Ar or phthalonitrile and metal salt substituted by rigid unit Ar; It is prepared by connecting the rigid linking group Q to the parent phthalocyanine ring, and then reacting with the rigid unit Ar. Wherein, halogenation may be chlorination or bromination, or a combination of bromine and chlorination.

[0045] As a method for reacting phthalic anhydride substituted by rigid unit Ar with metal salts, the following can be cited: reacting a hydroxyl derivative of Ar with 4-nitrophthalimide (CAS No. 89-40-7) and potassium carbonate Add it into a polar organic solvent, ...

Embodiment 1

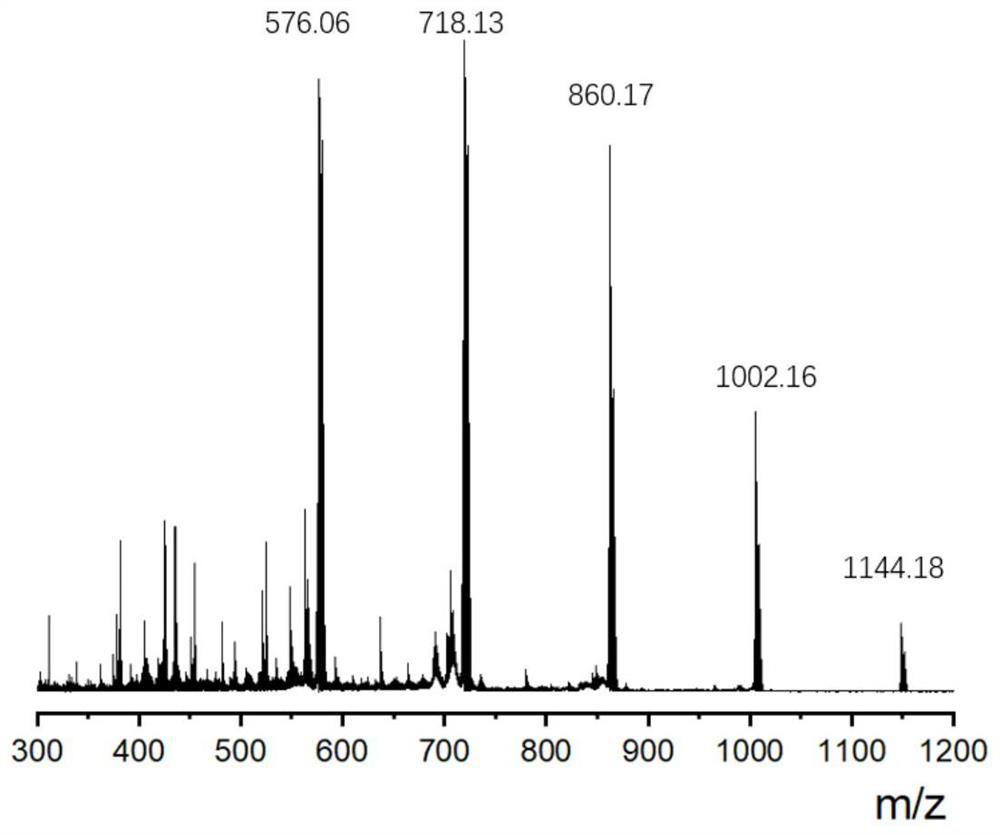

[0070] 1. Synthesis of Pigment Derivative 1

[0071] (1) Synthesis of zinc phthalocyanine-naphthalene

[0072]

[0073] Add 250ml of N,N-dimethylformamide (DMF), 37.83g of nitrophthalonitrile, and 34.60g of naphthol into a three-necked flask equipped with mechanical stirring, a condenser, and a thermometer, heat to 60°C, and add 66.24 g of anhydrous potassium carbonate, heated to 80°C and stirred overnight. The reacted solution was poured into water, continued to stir for 1 h, and then filtered. The filter cake was washed with 5% NaOH solution and water, and dried to obtain 52.45 g of phthalonitrile-O-naphthalene, with a yield of 96.7%.

[0074]Add 150g of n-pentanol, 14.18g of phthalonitrile, 15g of phthalonitrile-o-naphthalene into a three-necked flask equipped with mechanical stirring, condenser and thermometer, heat up to 100°C and stir to dissolve, add 6.06g of DBU , 3.40g zinc chloride, continue to heat up to 160 ℃, maintain 5h. The temperature of the system was lo...

Embodiment 2

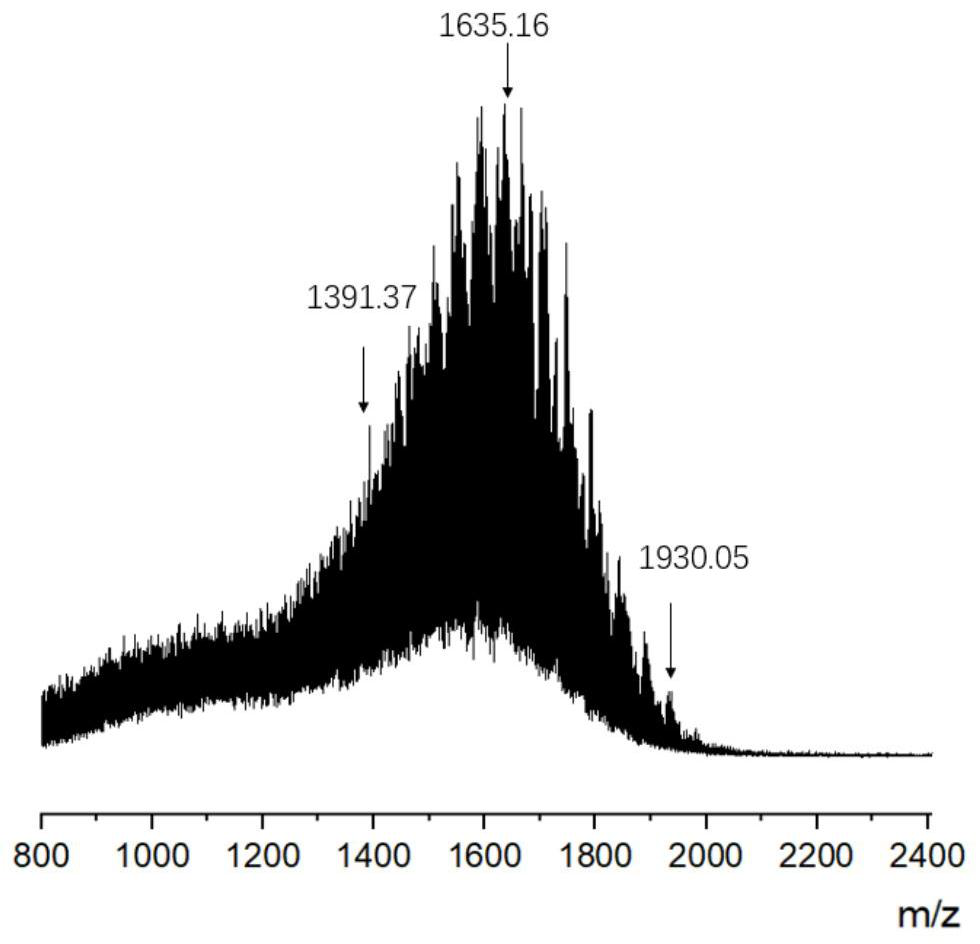

[0092] 1. Synthesis of Pigment Derivative 2

[0093] (1) Synthesis of copper phthalocyanine-sulfonic acid fluorene

[0094]

[0095] Add 600g of chlorosulfonic acid into a three-necked flask equipped with mechanical stirring, thermometer, and condenser, start stirring, and slowly add 120g of copper phthalocyanine at 45-50°C. After the feeding is completed, the temperature is raised to 128°C, and the reaction is kept for 4 hours (sampling and monitoring), and the temperature is lowered to 60-65°C. Within 2 hours, 150g of thionyl chloride is added dropwise. After the dropwise addition, the temperature is raised to 90°C and the reaction is continued for 30 minutes. Then raise the temperature to 105°C, react for 30 minutes, and then lower the temperature to 45°C. Pour the material into ice water, control the temperature not to exceed 5° C., filter, and wash the filter cake with ice water until pH=4 or more to obtain 1080 g of filter cake with a solid content of 18%. Store the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com