A kind of preparation method of anti-mud type sodium alginate side chain comb polycarboxylate superplasticizer

A comb-shaped polycarboxylic acid and sodium alginate technology, which is applied in the field of concrete admixtures, can solve the problems of poor clay adaptability, cumbersome synthesis process, poor initial flow performance of clay-resistant polycarboxylate water-reducing agent, etc., so as to reduce the use of Quantity, cost reduction, strong steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

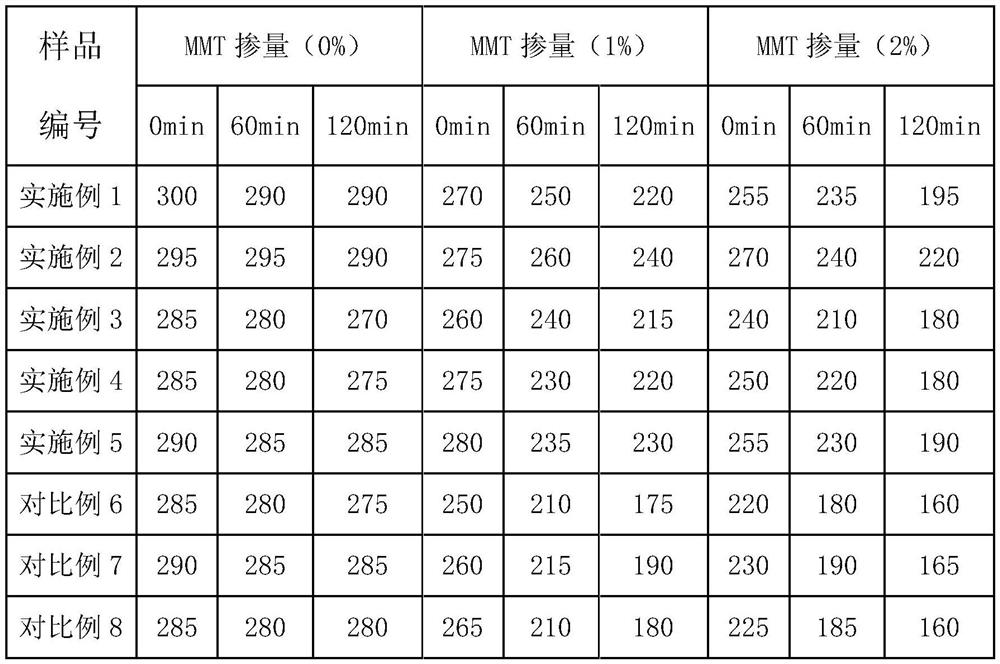

Examples

Embodiment 1

[0025] Preparation of anti-mud amides monomer:

[0026] (1) Add 150 parts of sodium alginate sequentially by weight into the reactor and stir overnight for 24 hours until the sodium alginate is completely dissolved. Then the pH value of the sodium alginate solution was adjusted to 3.6 with 5 parts of hydrochloric acid solution. Add 0.1 part of formaldehyde, 0.2 part of acrylamide and 0.4 part of cyclohexylisonitrile to the reaction kettle in sequence, and stir rapidly at room temperature to make the mixed solution undergo Uji reaction for 24 hours. After the reaction is completed, purification and drying are carried out to obtain an anti-sludge amide monomer containing a sodium alginate side chain;

[0027] Preparation of mud-resistant sodium alginate side chain comb-shaped polycarboxylate superplasticizer:

[0028] (2) successively by weight 200 parts of isopentenyl polyoxyethylene ethers namely TPEG2400, 0.1 part of anti-mud amide monomer of the sodium alginate side chain ...

Embodiment 2

[0034] Preparation of anti-mud amides monomer:

[0035] (1) Add 150 parts of sodium alginate sequentially by weight into the reactor and stir overnight for 24 hours until the sodium alginate is completely dissolved. Then the pH value of the sodium alginate solution was adjusted to 3.6 with 5 parts of hydrochloric acid solution. Add 0.1 part of formaldehyde, 0.2 part of acrylamide and 0.4 part of cyclohexylisonitrile to the reaction kettle in sequence, and stir rapidly at room temperature to make the mixed solution undergo Uji reaction for 24 hours. After the reaction is completed, purification and drying are carried out to obtain an anti-sludge amide monomer containing a sodium alginate side chain;

[0036] Preparation of mud-resistant sodium alginate side chain comb-shaped polycarboxylate superplasticizer:

[0037] (2) By weight, 175 parts of TPEG2400, 0.1 part of anti-mud amide monomer of sodium alginate side chain synthesized in step (1), 15 parts of small monomer acrylic...

Embodiment 3

[0043] Preparation of anti-mud amides monomer:

[0044] (1) Add 150 parts of sodium alginate sequentially by weight into the reactor and stir overnight for 24 hours until the sodium alginate is completely dissolved. Then the pH value of the sodium alginate solution was adjusted to 3.6 with 5 parts of hydrochloric acid solution. Add 0.1 part of formaldehyde, 0.2 part of acrylamide and 0.4 part of cyclohexylisonitrile to the reaction kettle in sequence, and stir rapidly at room temperature to make the mixed solution undergo Uji reaction for 24 hours. After the reaction is completed, purification and drying are carried out to obtain an anti-sludge amide monomer containing a sodium alginate side chain;

[0045] Preparation of mud-resistant sodium alginate side chain comb-shaped polycarboxylate superplasticizer:

[0046] (2) By weight, 150 parts of TPEG2400, 0.1 part of anti-mud amide monomer of sodium alginate side chain synthesized in step (1), 15 parts of small monomer acrylic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com