Novel Co@CoP2/CF full-electrolysis water electrocatalyst

A catalyst, hydropower technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Set the area to 1×1cm 2 Foam copper (CF) sheet placed in 3mol L -1 Ultrasonic in the HCl solution for 20min, then ultrasonically cleaned with deionized water and absolute ethanol and dried;

[0020] (2) Take 2mmol Co(NO 3 ) 2 ·6H 2 O, 10mmol NH 4 F, 10mmol CH 4 N 2 O and 0.33mmol phytic acid were dissolved in deionized water to obtain a 20mL mixed solution;

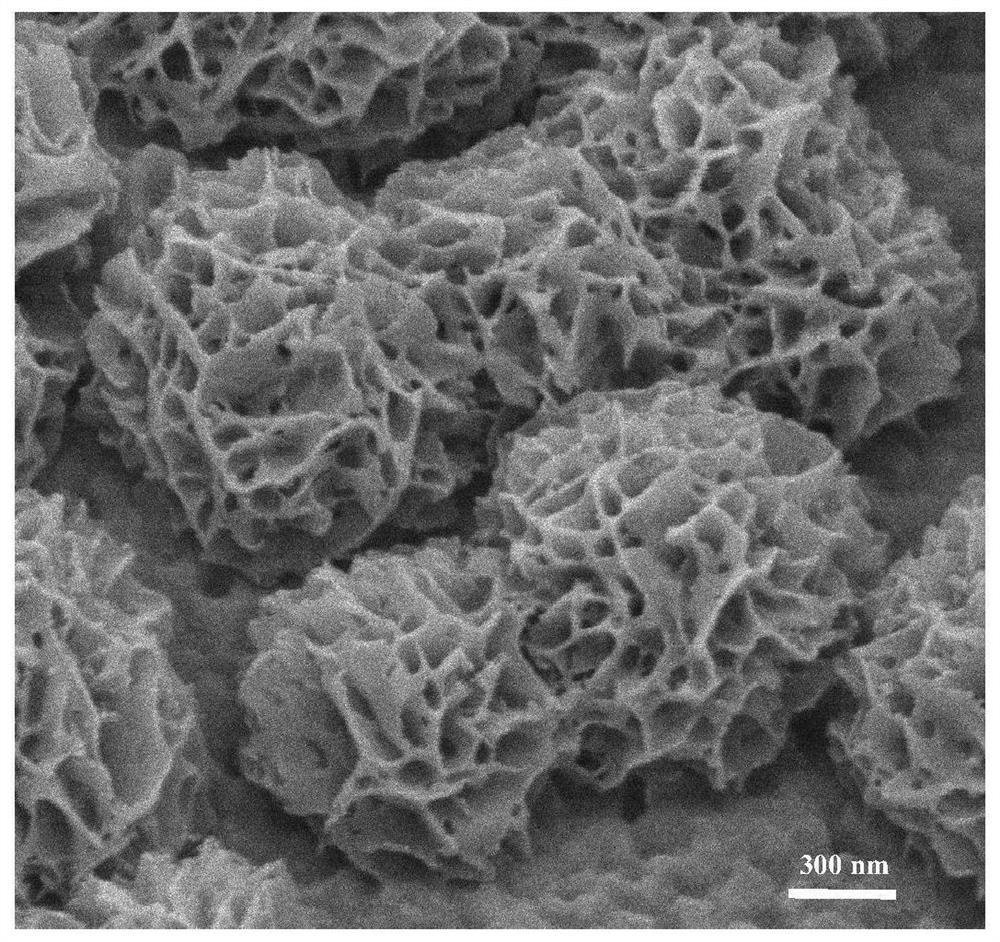

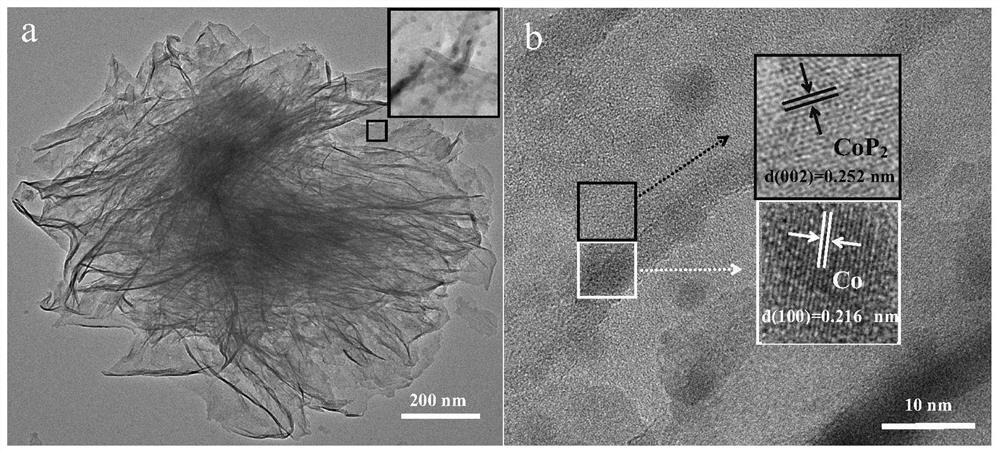

[0021] (3) Transfer the CF pretreated in step (1) and the mixed solution prepared in step (2) to a reaction kettle, and conduct a hydrothermal reaction at 120°C for 8 hours. After it is naturally cooled to room temperature, it is centrifuged and separated with Wash with deionized water and absolute ethanol, and vacuum-dry the resulting precipitate;

[0022] (4) place the precipitate obtained in step (3) with a porcelain boat, and place it in a tube furnace, 2 Atmosphere, at 5°C·min -1 The heating rate was increased to 280°C, kept for 2 hours, and naturally cooled to room temperature to obtain the targ...

Embodiment 2

[0025] (1) Pretreat CF according to the method of step (1) in Example 1;

[0026] (2) Take 2mmol Co(NO 3 ) 2 ·6H 2 O, 10mmol NH 4 F, 10mmol CH 4 N 2 O, and 0.5mmol phytic acid were dissolved in deionized water to obtain a 20mL mixed solution;

[0027] (3) operate according to embodiment 1 step (3);

[0028] (4) operate according to embodiment 1 step (4), make target catalyst;

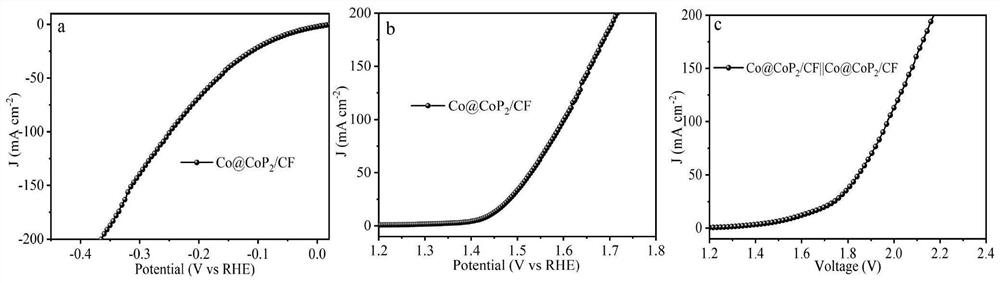

[0029](5) Hg / HgO, platinum wire and the prepared Co@CoP 2 / CF electrode is reference electrode, counter electrode and working electrode, at 1mol L -1 The HER, OER and total water splitting performance of the prepared samples were tested in the KOH electrolyte, and the results are shown in Figure 4(a~c). attached Figure 4 (a) and (b) show that at 1mol L -1 10mAcm in KOH solution -2 When the current density of Co@CoP 2 / CF catalyzes HER and OER with overpotentials of 65mV and 226mV, respectively. Figure (c) shows that Co@CoP 2 / CF||Co@CoP 2 The total water splitting system of / CF only nee...

Embodiment 3

[0031] (1) Pretreat CF according to the method of step (1) in Example 1;

[0032] (2) Take 2mmol Co(NO 3 ) 2 ·6H 2 O, 10mmol NH 4 F, 10mmol CH 4 N 2 O, and 0.2mmol phytic acid were dissolved in deionized water to obtain a 20mL mixed solution;

[0033] (3) operate according to embodiment 1 step (3);

[0034] (4) operate according to embodiment 1 step (4), make target catalyst;

[0035] (5) Hg / HgO, platinum wire and the prepared Co@CoP 2 / CF electrode is reference electrode, counter electrode and working electrode, at 1mol L -1 The HER, OER and total water splitting performance of the prepared samples were tested in the KOH electrolyte, and the results are shown in Figure 5(a-c). attached Figure 5 (a) and (b) show that at 1mol L -1 10mAcm in KOH solution -2 When the current density of Co@CoP 2 / CF catalyzes HER and OER with overpotentials of 70mV and 244mV, respectively. Figure (c) shows that Co@CoP 2 / CF||Co@CoP 2 The total water splitting system of / CF only ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com