Preparation and application of plasma-treated ultrathin ternary nanosheet FePSe3 for bifunctional electrocatalyst of air electrode of high-efficiency zinc air battery

A bifunctional catalyst, zinc-air battery technology, applied in fuel cell type half cells and secondary cell type half cells, battery electrodes, nanotechnology for materials and surface science, etc., can solve the obstacles to wide application, High cost, scarcity, limited reserves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

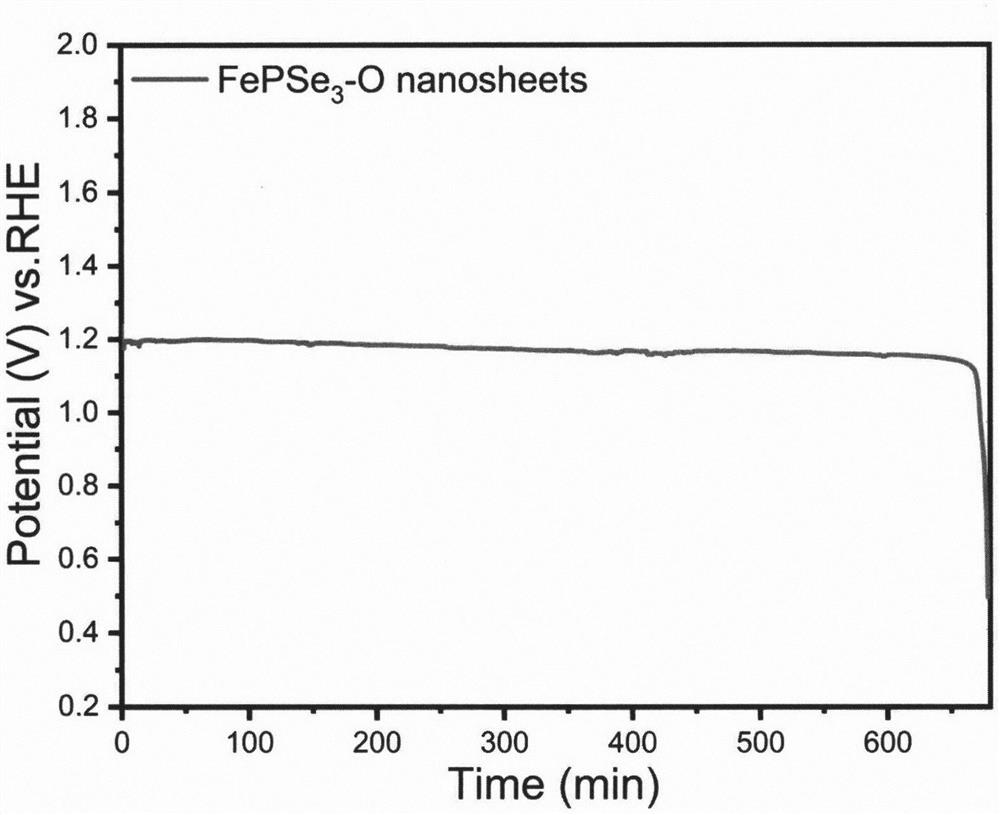

Examples

Embodiment 1

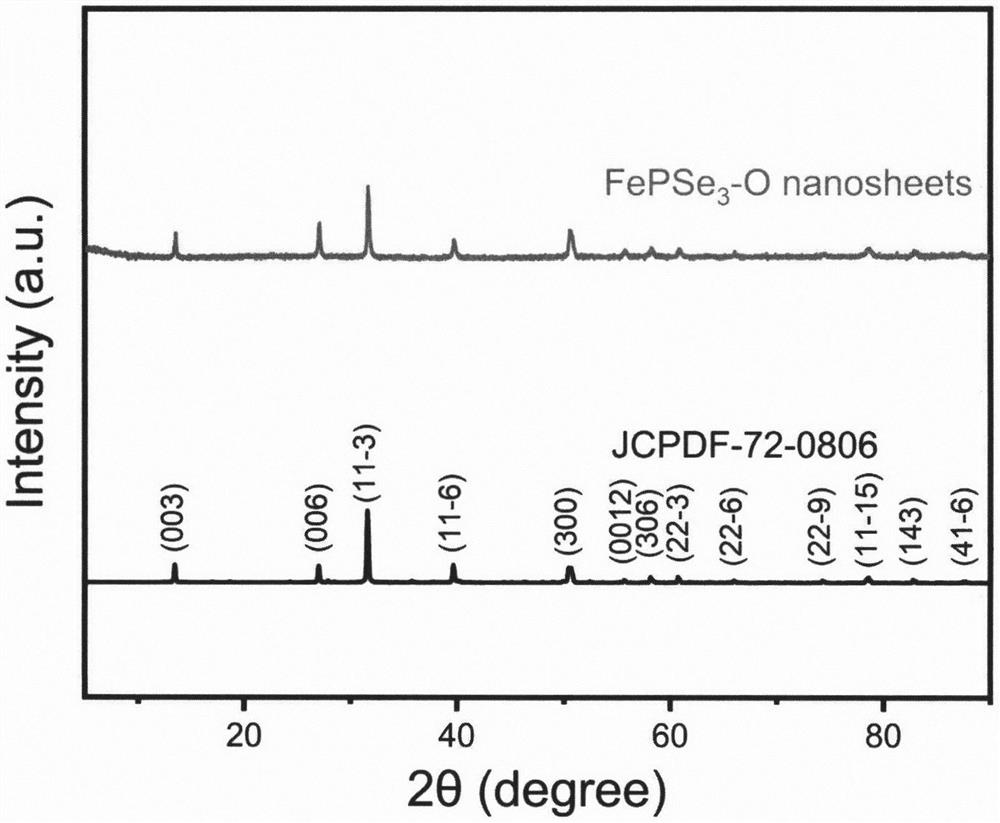

[0024] (1) FePSe 3 Crystal preparation. Weigh Fe powder (50nm), P powder and Se powder according to the molar mass ratio of 1:1:3 to weigh a total of 500mg, and seal it in a quartz tube under vacuum. The inner diameter of the quartz tube is about 16mm and the length is about 15cm. Use the CVT method Heat to 750°C in a box furnace and keep for 7 days with a heating rate of 2°C / min. After cooling to room temperature, the bulk FePSe 3 Crystals, ground to a homogeneous powder and stored in a dry cabinet.

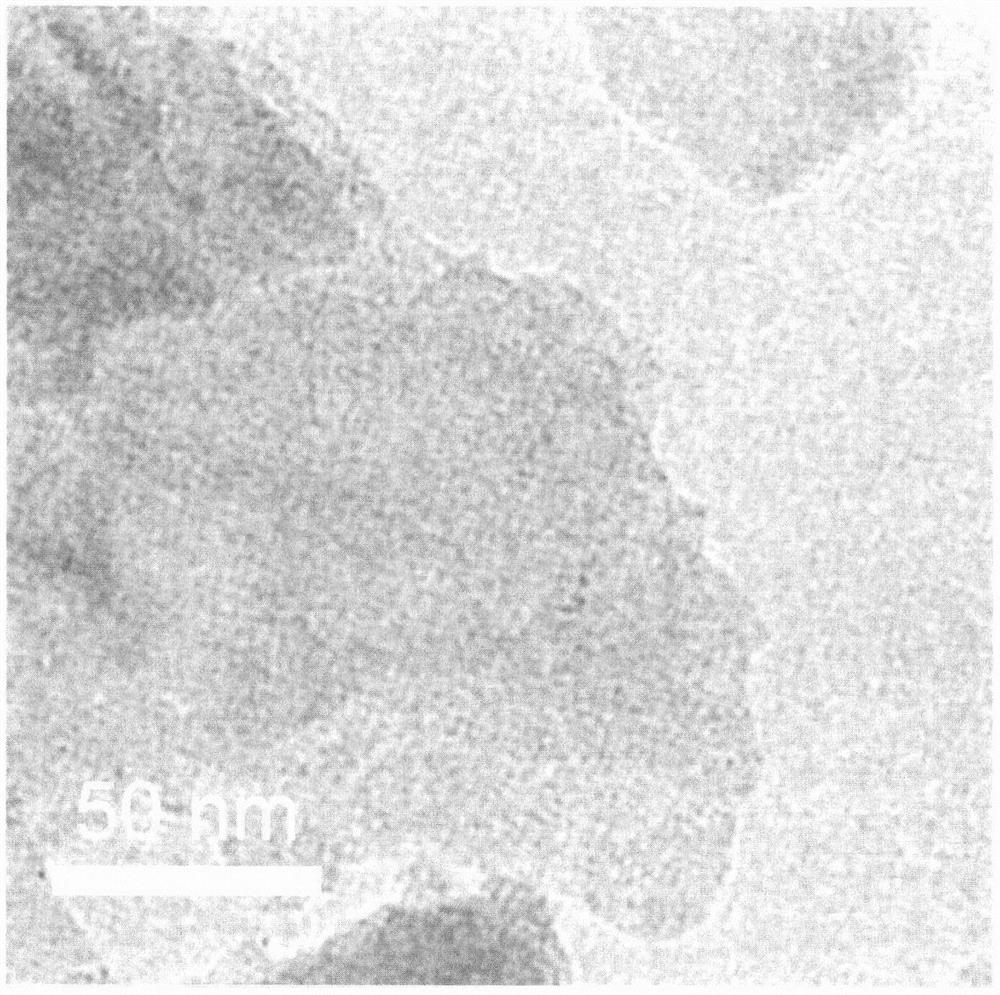

[0025] (2) FePSe 3 Preparation of nanosheets. Weigh 200mg block of FePSe 3 The crystals were dispersed in absolute ethanol solution and ultrasonically treated to obtain uniformly dispersed black FePSe 3 The ethanol mixed solution was stripped by tip ultrasonic treatment, and the mixed solution was centrifuged at 1000rpm for 3 times, half an hour each time, and the supernatant was separated and collected. Absolute ethanol was centrifuged at 6000rpm 3 times for half an hour...

Embodiment 2

[0032] Prepare comparative sample substantially according to the method identical with embodiment 1, difference is not carrying out plasma processing after tip ultrasonic stripping treatment, obtains comparative sample catalyst FePSe 3 Nanosheets.

[0033] (1) FePSe 3 Crystal preparation. Weigh Fe powder (50nm), P powder and Se powder according to the molar mass ratio of 1:1:3 to weigh a total of 500mg, and seal it in a quartz tube under vacuum. The inner diameter of the quartz tube is about 16mm and the length is about 15cm. Use the CVT method Heat to 750°C in a box furnace and keep for 7 days with a heating rate of 2°C / min. After cooling to room temperature, the bulk FePSe 3 Crystals, ground to a homogeneous powder and stored in a dry cabinet.

[0034] (2) FePSe 3 Preparation of nanosheets. Weigh 200mg block of FePSe 3 The crystals were dispersed in absolute ethanol solution and ultrasonically treated to obtain uniformly dispersed black FePSe 3 The ethanol mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com