Anti-flocculating agent, preparation method and application thereof

A technology of deflocculants and initiators, applied in the field of deflocculants and their preparation, can solve problems such as poor fluidity and increased viscosity of concrete, and achieve the effects of improved fluidity, stable structure, and unfavorable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

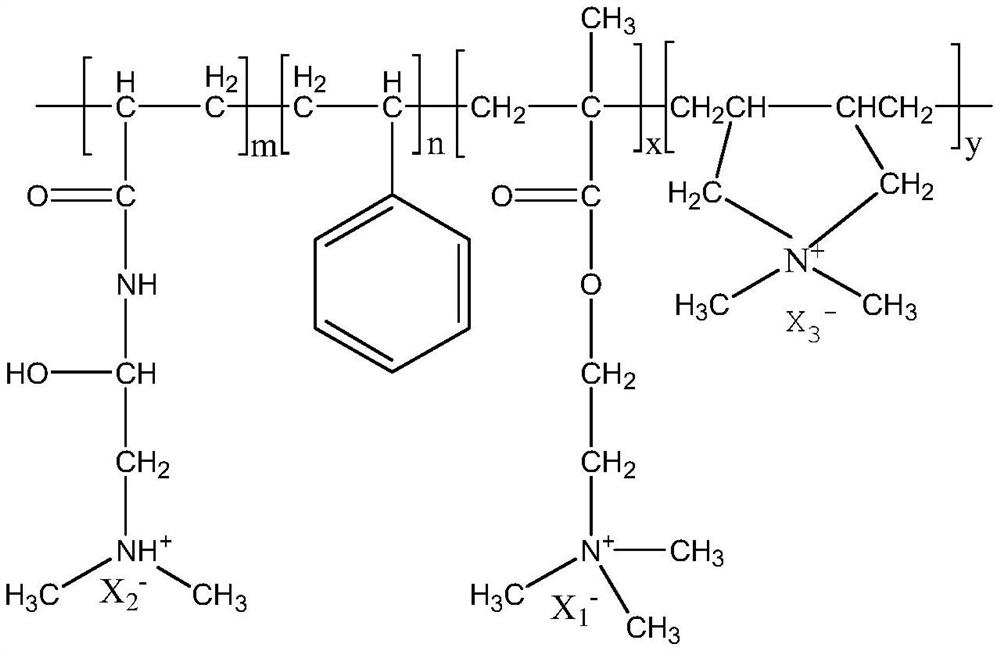

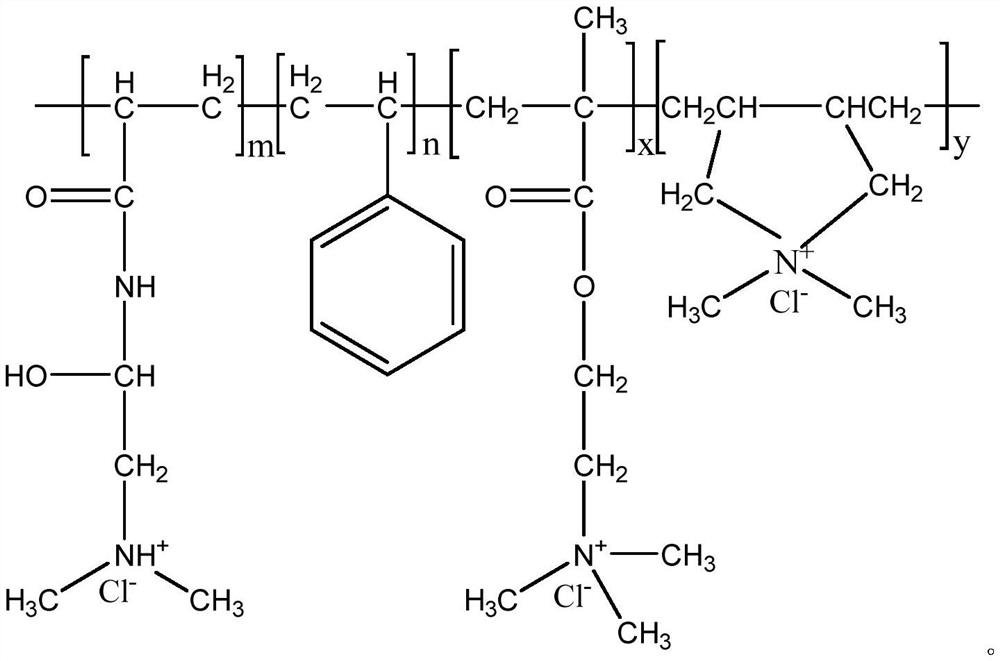

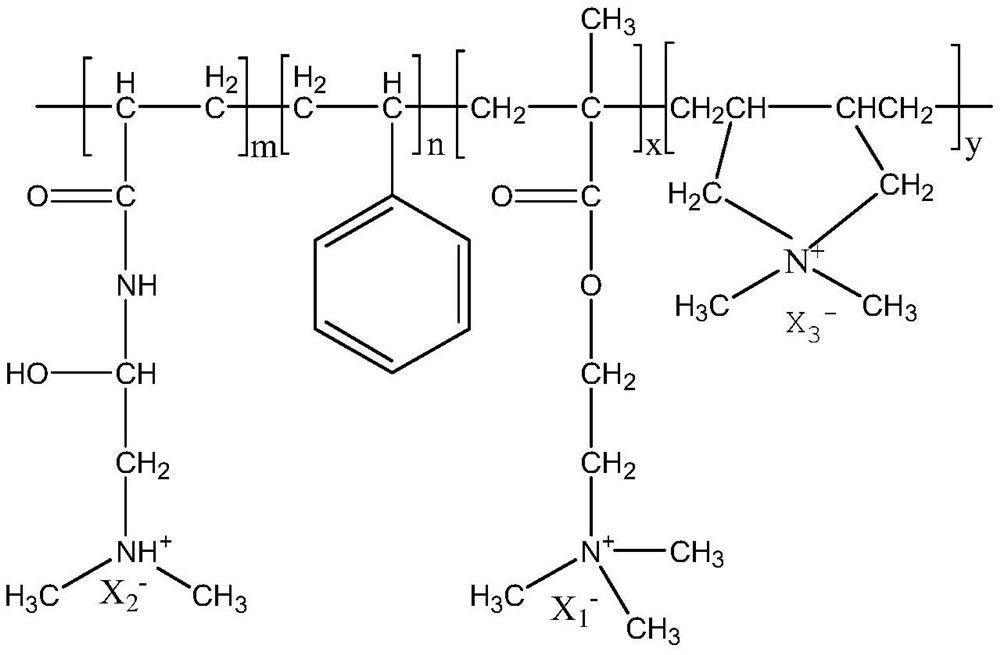

Image

Examples

Embodiment 1

[0046] This embodiment provides a preparation method of a deflocculant, comprising the following steps,

[0047] Introduce nitrogen into the reaction kettle, dry the water in the reaction kettle, add 446.26kg epichlorohydrin, control the temperature of the material at 50±2°C; mix 132.61kg deionized water, 1.21kg potassium hydroxide and 285.72kg acrylamide Mix and stir to dissolve to form a mixed solution A for later use; control the rate of addition, so that the mixed solution A is evenly added dropwise to the reactor, the dropping time is 60 minutes, and react at 55±5°C for 60 minutes after the dropping; then add Adjust the pH to 4-5 with 4.02L of hydrochloric acid, add 549.12kg of 33% dimethylamine aqueous solution evenly in the reaction kettle, the time of dropping is 60min, react at 65±5℃ for 60min after the addition, and then add 12.20L of hydrochloric acid Stir evenly, and adjust the pH to obtain a cationic monomer-containing solution. The solid content of the cationic m...

Embodiment 2

[0050] This embodiment provides a kind of preparation method of deflocculant, and the preparation method of cationic monomer is the same as embodiment 1, comprises the following steps,

[0051] Add 127.27kg of deionized water into a reaction kettle, and control its temperature at 50±2°C; mix 142.54kg of deionized water and 52.43kg of ammonium persulfate, and stir to dissolve it to form a uniform mixed solution B; Ionized water, 323.19kg of cationic monomer solution, 264.33kg of methacryloyloxyethyltrimethylammonium chloride, 14.64kg of mercaptopropionic acid and 11.96kg of sodium bisulfite were mixed and stirred to dissolve to form a uniform mixed solution C: Add the mixed solution B and the mixed solution C in the reaction kettle dropwise, and the dropping time is 120 minutes. After the dropping, react at 55±5°C for 2 hours to obtain the deflocculant.

Embodiment 3

[0053] This embodiment provides a kind of preparation method of deflocculant, and the preparation method of cationic monomer is the same as embodiment 1, comprises the following steps,

[0054] Add 134.83kg of deionized water into a reaction kettle, and control its temperature at 50±2°C; mix 151.00kg of deionized water and 55.55kg of ammonium persulfate, and stir to dissolve it to form a uniform mixed solution B; Ionized water, 171.23kg cationic monomer solution, 14.02kg styrene, 140.02kg methacryloxyethyltrimethylammonium chloride, 181.68kg dimethyl diallyl ammonium chloride solution (dimethyl diallyl The solid content of allyl ammonium chloride is 60%), 15.50kg mercaptopropionic acid and 12.67kg sodium bisulfite mix, stir and make it dissolve to form uniform mixed solution C; In reactor, drop mixed solution B and mix For solution C, the dropping time is 120 minutes. After the dropping, react at 55±5°C for 2 hours to obtain the deflocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com