Thick oil viscosity-reducing synergistic composition and preparation method and application thereof

A composition and viscosity-reducing technology, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and mining, can solve the problems of high concentration of chemical agents and low solubilization rate of carbon dioxide, etc., and achieve reduction in dosage and structure Flexible and adjustable, strengthen the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

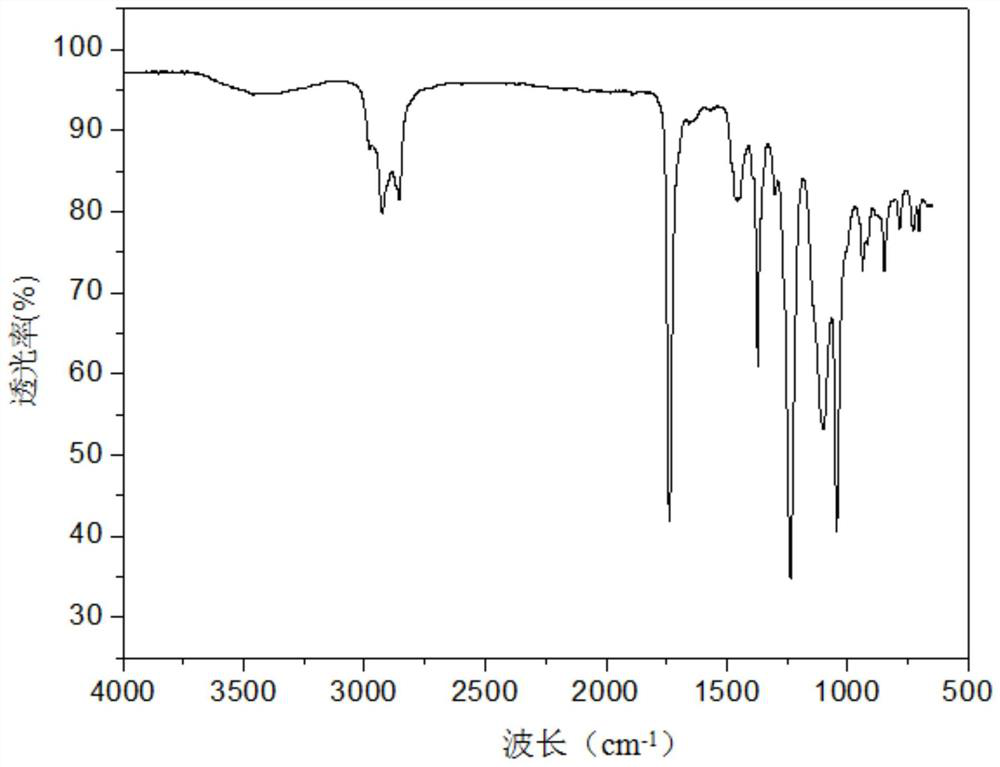

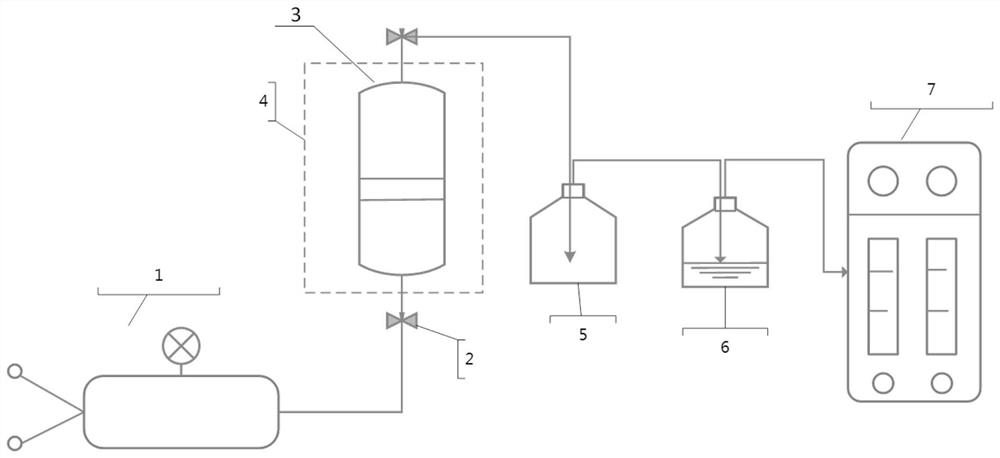

Method used

Image

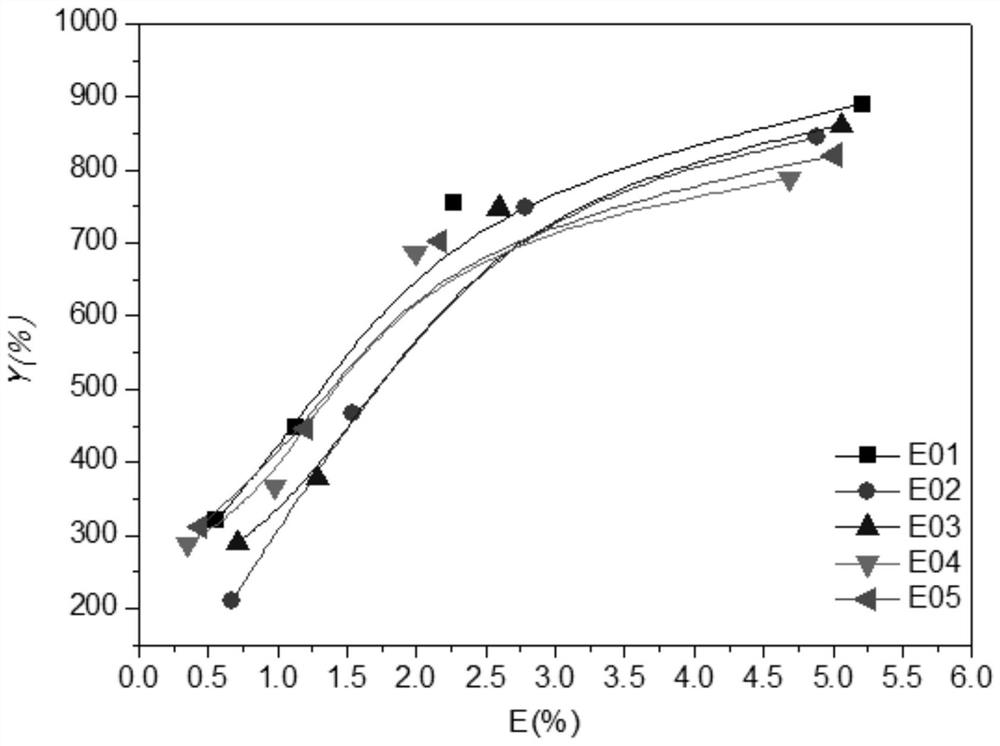

Examples

Embodiment 1

[0081] [Example 1] Preparation of viscosity-reducing and synergistic composition E01

[0082] ①Add 110.0 g (1 mole) of hydroquinone and 8.8 g of potassium hydroxide to a 2L pressure reactor equipped with a stirring device, and when heated to 80-90°C, turn on the vacuum system and dehydrate under high vacuum for 1 hour. Then replace it with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 150°C and slowly introduce 350.9 grams (6.05 moles) of propylene oxide, control the pressure ≤ 0.60Mpa, and adjust the temperature to 160°C after the reaction of propylene oxide is completed. Slowly inject 291.6 grams (4.05 moles) of butylene oxide at ℃, and the pressure is ≤0.60Mpa. After the reaction, lower the temperature to 90°C, remove the low boilers in vacuum, neutralize and dehydrate after cooling to obtain hydroquinone polyoxypropylene (6) polyoxybutylene (4) ether (R 1 =R 2 = H, R 3 =CH 3 , R 4 =C 2 h 5 , a=3, b=2, c=0, d=0, j=2) 690.8 g, yield 92.6%...

Embodiment 2

[0085] [Example 2] Preparation of viscosity-reducing synergistic composition E02

[0086] ① Add 110.0 g (1 mole) of hydroquinone and boron trifluoride etherate complex into a three-necked flask with a stirring dropping funnel, and stir evenly. When the temperature was raised to a certain temperature, 203.6 grams (2.2 moles) of epichlorohydrin was slowly added dropwise, and after the drop was completed, it was maintained for another 2 hours. Unreacted epichlorohydrin was distilled off under reduced pressure, and an ethanol solution of sodium hydroxide was added and stirred. Filter to remove the generated sodium chloride, then distill off ethanol and water under reduced pressure, and filter to remove the residual sodium chloride while hot to obtain hydroquinone diglycidyl ether.

[0087] ② Add 222.1 grams (1 mole) of hydroquinone diglycidyl ether and 9.9 grams of potassium hydroxide to a 2L pressure reactor equipped with a stirring device. Dehydrate for 1 hour, then replace wi...

Embodiment 3

[0091] [Example 3] Preparation of viscosity-reducing and synergistic composition E03

[0092] With the method of Example 1, the viscosity-reducing and synergistic composition E03 was prepared, and the composition is shown in Table 1.

[0093] ①Add 318.0 grams (1 mole) of cetylphenol, 5.9 grams of potassium hydroxide and 2.5 grams of potassium carbonate to a 2L pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system and Dehydrate under vacuum for 1 hour, then replace with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 150°C and slowly introduce 176.9 grams (3.05 moles) of propylene oxide, control the pressure ≤ 0.60Mpa, after the reaction of propylene oxide is completed Then adjust the temperature to 140° C. and slowly inject 88.0 g (2.0 moles) of ethylene oxide to make it, and the pressure is ≤0.60 MPa. After the reaction, lower the temperature to 90°C, remove low boilers in vacuum, neutralize and dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com