Composite magnet assembled by multiple permanent magnet main phase functional elements, and preparation method thereof

A technology of composite magnets and functional primitives, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of low magnetic performance, no more than 30wt.%, and difficulty in improving the magnetic performance of Ce-containing magnets. Achieve the effects of high saturation magnetization, high anisotropy field, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

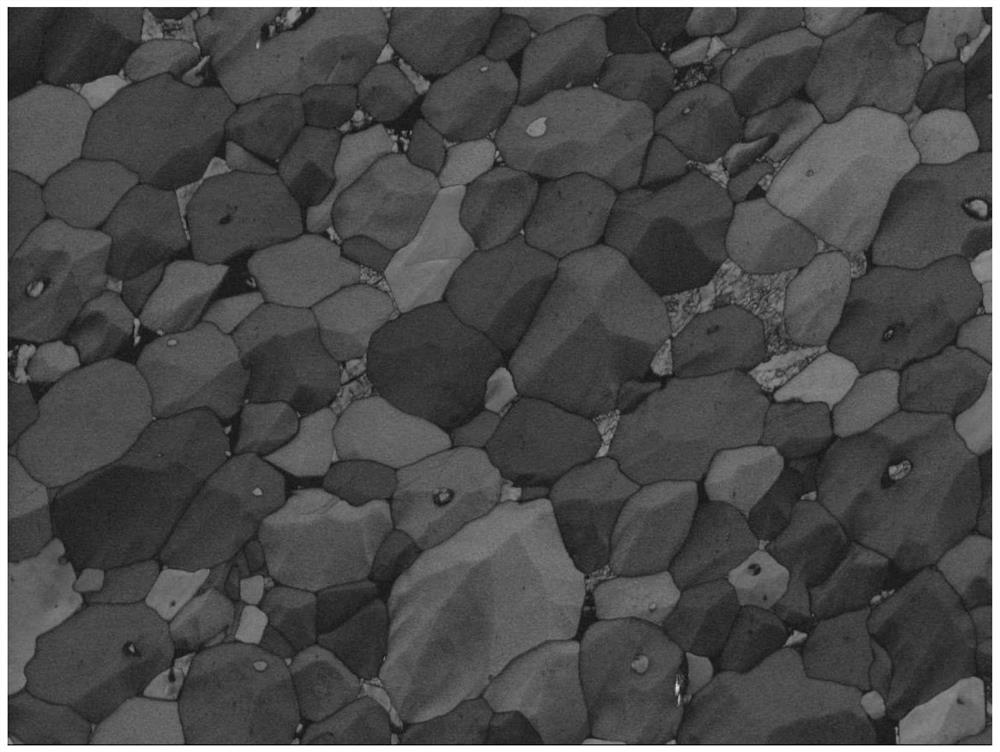

Image

Examples

Embodiment 1

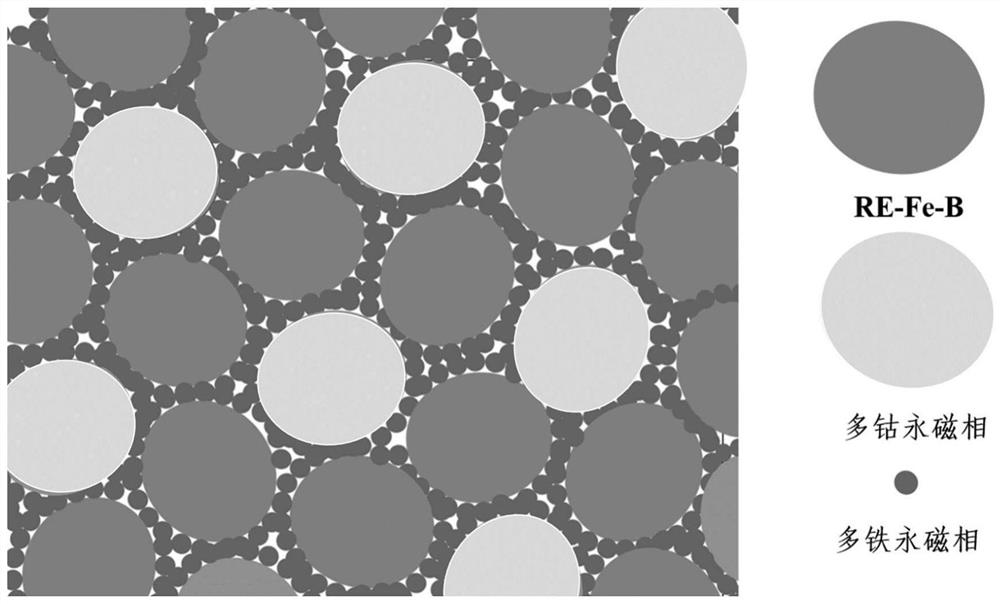

[0074] Composite magnets are prepared according to the above method, and at least two main phase alloys (Nd, RE')-Fe-TM-B and (RE", Ce)-Fe-TM-B of different functional units are prepared, and their respective Anisotropy field H a The ratio range of the anisotropy constant is 1.144 to 2.700, the ratio range of the anisotropy constant is 1.152 to 2.950, and the mass percentage of the final chemical composition of the magnet is (Nd 80 Ce 20 ) 30.00 Febal B 0.95 tm 0.70 (TM=Ga, Co, Cu, Al), in which 20wt.% of Nd is replaced by Ce, the spectral valence state of Ce in the magnet is about +3.09, and a magnet with high Ce content and high energy product is obtained.

[0075]

Embodiment 2

[0077] Composite magnets are prepared according to the above method, at least two main phase alloys (Nd, RE')-Fe-TM-B and (RE", Ce)-Fe-TM-B of different functional units are prepared, and their respective Anisotropy field H a The ratio range of the anisotropy constant is 1.144 to 2.700, the ratio range of the anisotropy constant is 1.152 to 2.950, and the mass percentage of the final chemical composition of the magnet is (Nd 20 Ce 80 ) 30.00 Febal B 0.95 tm 0.70 (TM=Ga, Co, Cu, Al), in which 80wt.% of Nd is replaced by Ce, the spectral valence state of Ce in the magnet is about +3.08, and the magnet with high Ce content and high magnetic energy product is obtained.

[0078]

Embodiment 3

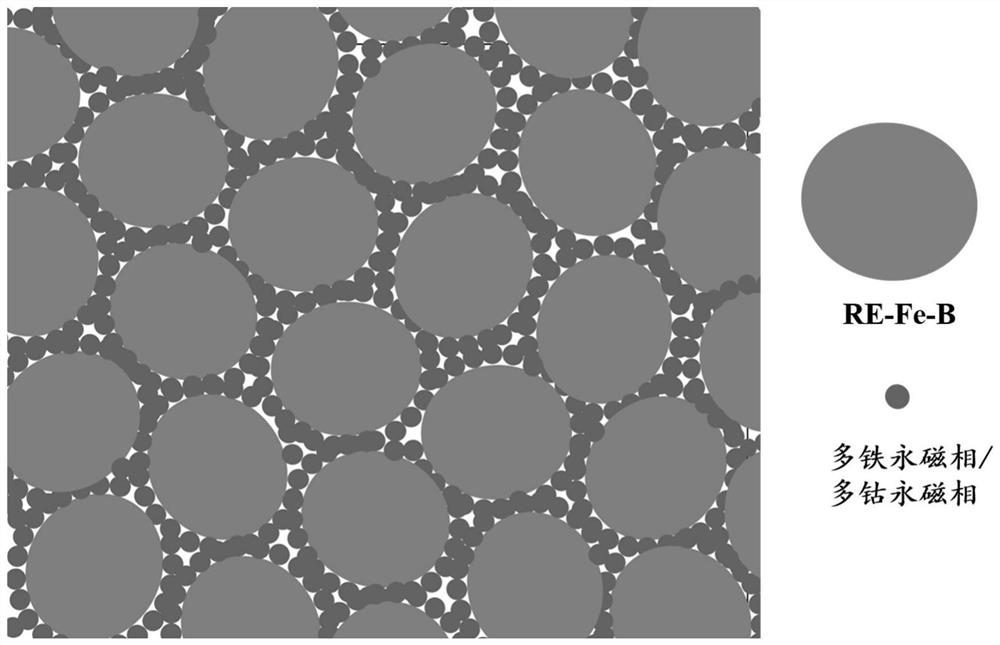

[0080] Composite magnets are prepared according to the above method. The main main phase element of the final magnet is the permanent magnetic phase containing Nd-Fe-B and polycobalt (RE', Nd)-Fe-TM-Co-B, and its magnetocrystalline anisotropy constant K 1 (A) / K 1 (B) The ratio range is 0.990 ~ 1.260, and the mass percentage of the chemical composition is Nd 30.00 FebalCo 60 B 0.95 tm 0.70 (TM=Ga, Co, Cu, Al), Fe is replaced by 60wt.% Co, the spectral valence state of Ce in the magnet is about +3.09, and a magnet with high Ce content and high Co is obtained.

[0081]

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com