Manufacturing method of heterojunction cell , heterojunction cell and solar cell module

A technology of a heterojunction cell and a manufacturing method, applied in the field of solar cells, can solve the problems of poor conductivity of conductive films and high production costs, and achieve the effects of increasing absorption probability, improving internal reflection, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

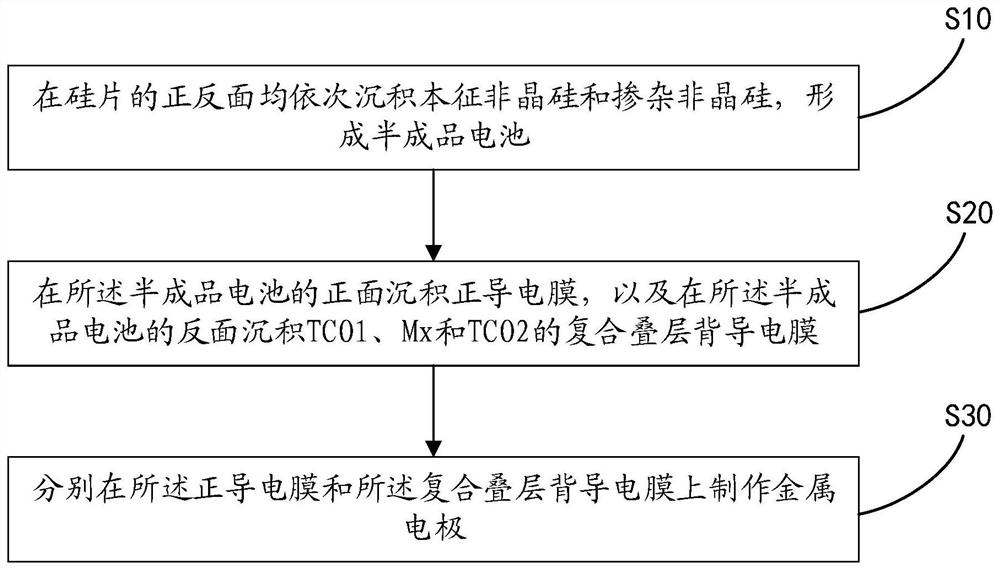

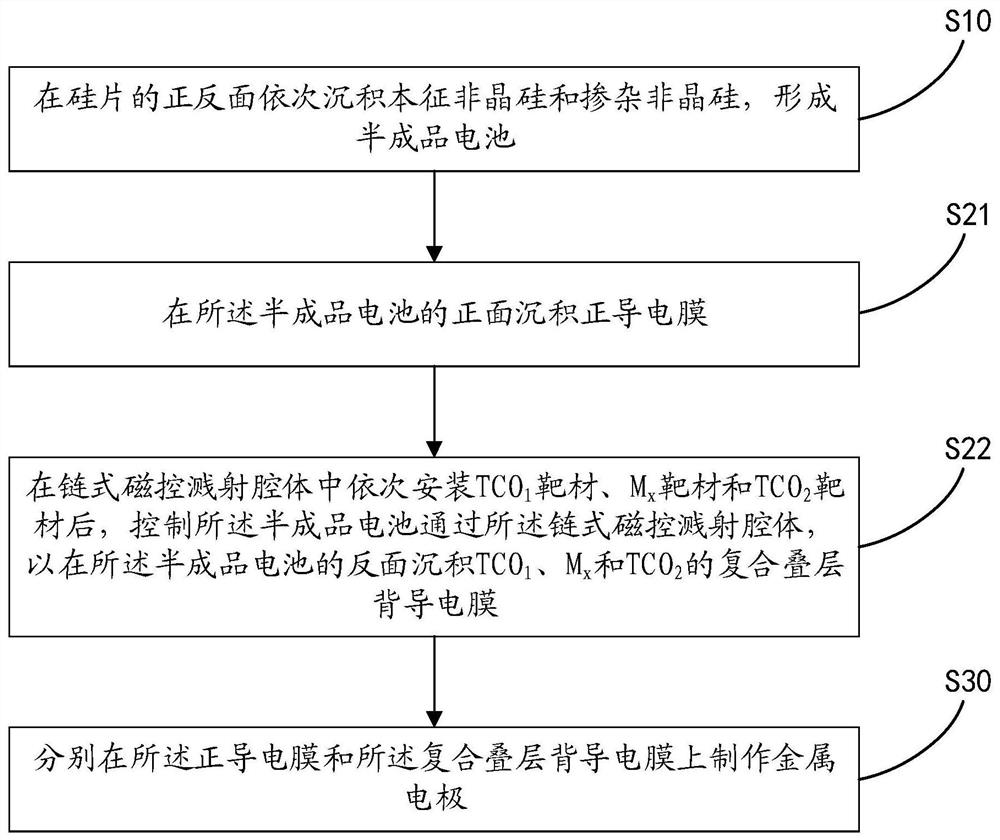

[0044] refer to figure 1 , the first embodiment provides a method for manufacturing a heterojunction battery, including the following steps:

[0045] S10, sequentially deposit intrinsic amorphous silicon and doped amorphous silicon on the front and back of the silicon wafer to form a semi-finished battery;

[0046] S20, depositing a positive conductive film on the front side of the semi-finished battery, and depositing TCO on the back side of the semi-finished battery 1 , M x and TCO 2 Composite laminated back conductive film;

[0047] S30, making metal electrodes on the positive conductive film and the composite laminated back conductive film respectively;

[0048] Among them, TCO 1 and TCO 2 Aluminum-doped zinc oxide, tin-doped indium oxide, indium-doped zinc oxide, gallium-doped zinc oxide, indium-gallium-doped zinc oxide, tungsten-doped indium oxide, molybdenum-doped indium oxide or zirconium-doped indium oxide, M x It is silver, aluminum, copper or silver-copper al...

Embodiment 2

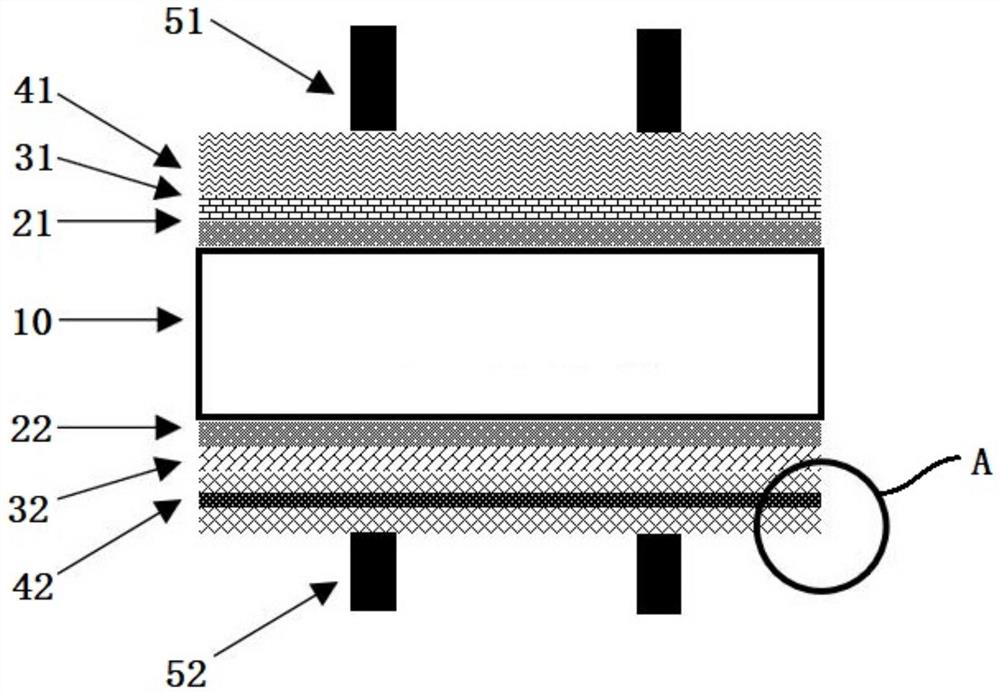

[0070] refer to image 3 , this embodiment 2 provides a heterojunction battery, which is prepared by the manufacturing method of the heterojunction battery as described in the first embodiment, and the heterojunction battery includes:

[0071] Wafer 10;

[0072] Intrinsic amorphous silicon and doped amorphous silicon respectively arranged on the front and back of the silicon wafer 10;

[0073] A positive conductive film 41 disposed on the doped amorphous silicon on the front side, and a TCO disposed on the doped amorphous silicon on the back side 1 , M x and TCO 2 Composite laminate back conductive film 42;

[0074] Metal electrodes respectively arranged on the positive conductive film 41 and the composite laminate back conductive film 42;

[0075] Among them, TCO 1 and TCO 2 is aluminum-doped zinc oxide, tin-doped indium oxide, indium-doped zinc oxide, gallium-doped zinc oxide, indium-gallium-doped zinc oxide, tungsten-doped indium oxide, molybdenum-doped indium oxide ...

Embodiment 3

[0079] The third embodiment provides a solar cell module, including the heterojunction cell as described in the second embodiment. Since the optical properties of the back conductive film of the heterojunction battery are not as high as those of the front conductive film, an ultra-thin metal layer is introduced into the composite laminated back conductive film 42 to greatly improve the conductivity of the back film. The plasmonic enhancement effect improves the internal reflection of long-wavelength transmitted light, increases its absorption probability in the silicon wafer 10, and generates more photocurrent; in addition, because the insertion of an ultra-thin metal layer can greatly improve the conductivity of the back film, It can make the pattern on the back only keep the welding main grid, and no fine grid lines are needed, thereby greatly reducing the consumption of silver paste on the back and reducing the production cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com