Pigment type roller pen ink capable of avoiding blurring of handwriting and preparation method thereof

A pen ink and pigment technology, which is applied in the field of pigment-type ballpoint pen ink and its preparation, can solve the problems of limited application range of water-based ballpoint pens, inability to use water-based ballpoint pens, and uncoordinated appearance, so as to prevent feathering and inking Smooth, tightly connected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

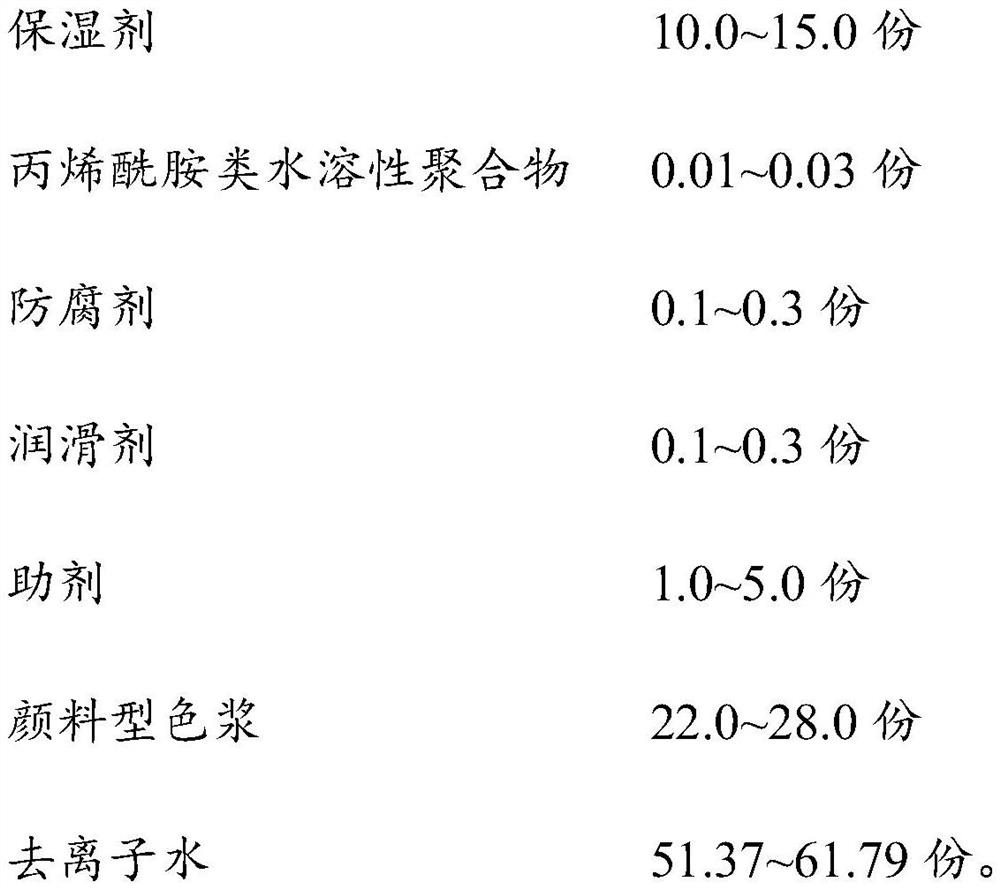

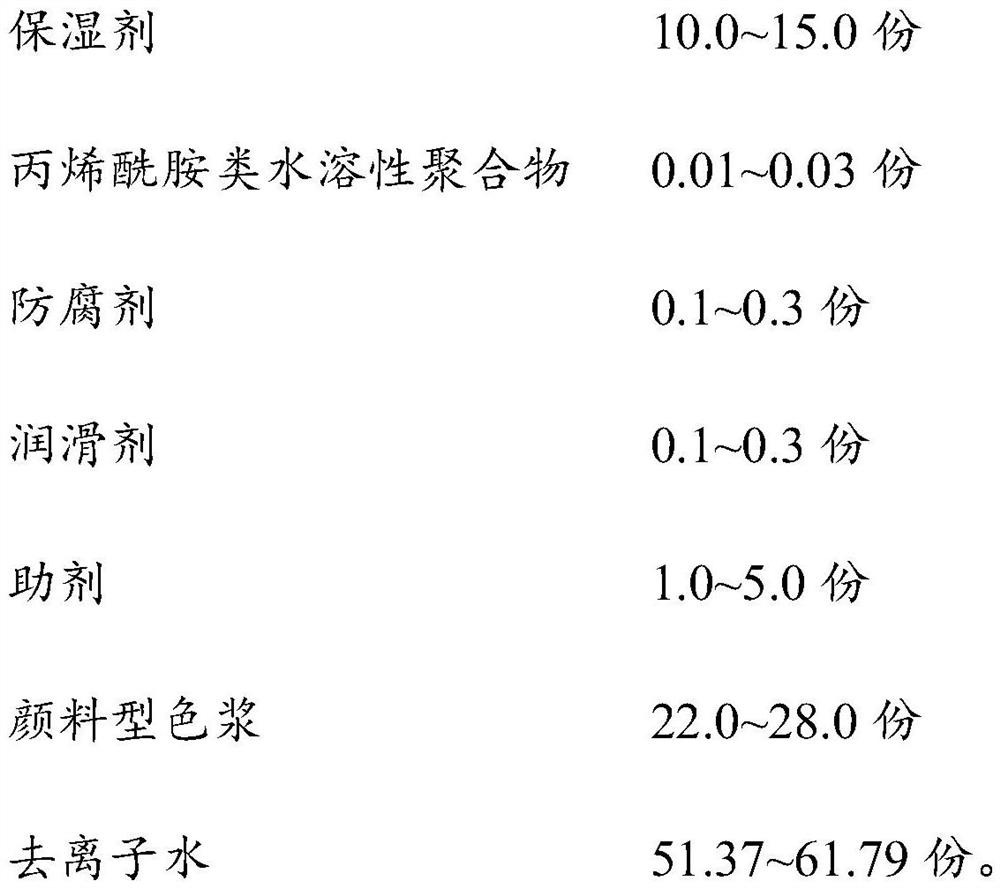

Method used

Image

Examples

Embodiment 1

[0029] Add 8.0 parts by weight of propylene glycol, 0.4 parts by weight of hydroxysulfonate, 0.3 parts by weight of polyoxyethylene polyoxypropylene monobutyl ether, 25.0 parts by weight of acrylic resin, and 1.0 parts by weight of triethanolamine to 65.0 parts by weight of deionized After uniform dispersion in water, add 25.0 parts by weight of high-pigment carbon black while stirring to fully wet the carbon black, and evenly disperse it in the above-mentioned mixed solution to make a color paste. Then emulsify the prepared color paste with an emulsifier for 10 minutes to obtain a color paste precursor; transfer the color paste precursor to a horizontal sand mill filled with 0.3mm diameter zirconium beads, and start circular grinding, During the grinding process, the temperature of the material is controlled at 25° C. until the particle size of the material is less than or equal to 88 nm, and the grinding is completed. After the material is discharged, the acrylic resin pigmen...

Embodiment 2

[0032] Add 7.0 parts by weight of propylene glycol, 0.3 parts by weight of hydroxysulfonate, 0.4 parts by weight of polyoxyethylene polyoxypropylene monobutyl ether, 20.0 parts by weight of acrylic resin, and 2.0 parts by weight of triethanolamine to 70.0 parts by weight of deionized After uniform dispersion in water, add 30.0 parts by weight of high-pigment carbon black while stirring to fully wet the carbon black, and evenly disperse it in the above-mentioned mixed solution to make a color paste. Then emulsify the prepared color paste with an emulsifier for 10 minutes to obtain a color paste precursor; transfer the color paste precursor to a horizontal sand mill filled with 0.4mm diameter zirconium beads, and start circular grinding, During the grinding process, the temperature of the material is controlled at 30°C until the particle size of the material is less than or equal to 90nm, and the grinding is completed, and the acrylic resin pigment paste is obtained after the mat...

Embodiment 3

[0035] (1) In parts by weight, 20.0 parts of deionized water was heated at a constant temperature of 65°C, and then 0.01 part of an acrylamide water-soluble polymer with a molecular weight of 3 million and a solid content of 88.5% was added under constant stirring. In deionized water, keep stirring until it is completely dissolved, and place it to cool to obtain a viscous aqueous solution of acrylamide water-soluble polymer;

[0036] (2) Add 10.0 parts of propylene glycol, 0.1 part of benzotriazole, 0.1 part of fatty acid polyoxyethylene ether, and 1.0 part of diethylene glycol into 10.0 parts of deionized water to obtain a mixture, and stir for 1.0 h to obtain an ink base liquid;

[0037] (3) Then, the acrylamide water-soluble polymer aqueous solution obtained by completely dissolving the step (1) is added into the ink base liquid of the step (2) under stirring state, and mixed and stirred for 1.0 h;

[0038] (4) Finally, add 22.0 parts of acrylic resin pigment paste with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com