Cast steel shot with low-carbon martensite structure and preparation process for cast steel shot

A technology of low-carbon martensite and cast steel shot, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of increased raw material cost and process cost, consumption of precious metal resources, poor fluidity of molten steel, etc., and achieve a reduction in broken rate , raw material cost control, and the effect of yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

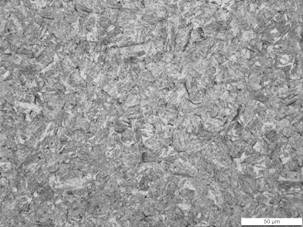

Embodiment 1

[0046] According to the cast steel shot of two middle carbon content of the present invention, its chemical composition is respectively:

[0047] ① 0.29%C, 2.05%Mn, 0.37%Si, 0.08%P, 0.039%S, the balance is Fe and unavoidable impurities and alloy elements brought in by raw materials during smelting;

[0048] ②0.28%C, 1.98%Mn, 0.37%Si, 0.02%Nb, 0.06%P, 0.037%S, the balance is Fe and unavoidable impurities and alloying elements brought in by raw materials during smelting.

[0049] Its preparation steps include:

[0050] S1. Put the raw materials into the medium-frequency induction furnace according to the weight ratio for smelting. The smelting temperature is 1650-1750°C. During the smelting process, the chemical composition is adjusted until the molten steel meets the chemical composition requirements;

[0051] S2. Continuously pour the smelted molten steel into a high-speed centrifugal forming machine, and throw it into a pool below 40°C under the action of centrifugal force t...

Embodiment 2

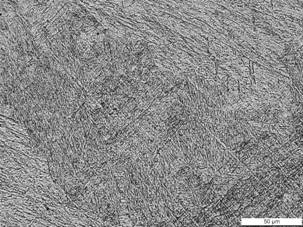

[0058] According to the chemical composition of the cast steel shot of two middle carbon content of the present invention is respectively:

[0059] ① 0.46%C, 1.63%Mn, 0.47%Si, 0.11%Ti, 0.07%P, 0.032%S, the balance is Fe and unavoidable impurities and alloy elements brought in by raw materials during smelting;

[0060] ②0.45%C, 1.59%Mn, 0.47%Si, 0.11%Ti, 0.05%Nb, 0.07%P, 0.031%S, the balance is Fe and unavoidable impurities and alloying elements brought in by raw materials during smelting.

[0061] Its preparation steps include:

[0062] S1. Put the raw materials into the medium-frequency induction furnace according to the weight ratio for smelting. The smelting temperature is 1650-1750°C. During the smelting process, the chemical composition is adjusted until the molten steel meets the chemical composition requirements;

[0063] S2. Continuously pour the smelted molten steel into a high-speed centrifugal forming machine, and throw it into a pool below 40°C under the action of...

Embodiment 3

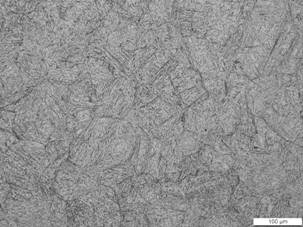

[0070] According to the cast steel shot of two high carbon contents of the present invention, its chemical composition is respectively:

[0071] ① 0.71%C, 1.25%Mn, 0.31%Si, 0.12%Ti, 0.07%P, 0.029%S, the balance is Fe and unavoidable impurities and alloy elements brought in by raw materials during smelting;

[0072] ②0.69%C, 1.22%Mn, 0.30%Si, 0.12%Ti, 0.08%Nb, 0.06%P, 0.029%S, the balance is Fe and unavoidable impurities and alloying elements brought in by raw materials during smelting.

[0073] Its preparation steps include:

[0074] S1. Put the raw materials into the medium-frequency induction furnace according to the weight ratio for smelting. The smelting temperature is 1650-1750°C. During the smelting process, the chemical composition is adjusted until the molten steel meets the chemical composition requirements;

[0075] S2. Continuously pour the smelted molten steel into a high-speed centrifugal forming machine, and throw it into a pool below 40°C under the action of ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com