Anti-sea snake venom serum nano-membrane filtering method

A filtration method, nano-membrane technology, applied in the preparation method of peptides, chemical instruments and methods, from serum immunoglobulin, etc., can solve the problems of high cost of nano-membranes, achieve accelerated industrialization, reduce costs, and increase protein content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 A nano-membrane filtration method for anti-sea snake venom

[0034] Proceed as follows:

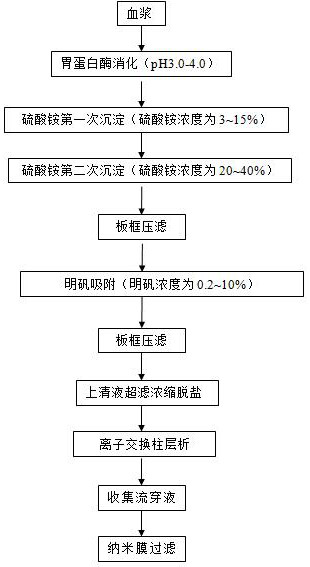

[0035] One, according to the present invention figure 1 In the technical process, the preparation of anti-sea snake venom chromatography flow-through solution specifically includes the following steps;

[0036] 1. Obtain plasma;

[0037] 2. Pepsin digestion (pH3.5);

[0038] 3. The first precipitation of ammonium sulfate (the concentration of ammonium sulfate is 7% (mass volume ratio w / v));

[0039] 4. The second precipitation of ammonium sulfate (the concentration of ammonium sulfate is 30% (w / v));

[0040] 5. Plate and frame filter press;

[0041] 6. Alum adsorption (alum concentration is 6% (w / v));

[0042] 7. Plate and frame filter press;

[0043] 8. Concentrate and desalt the supernatant by ultrafiltration; in this ultrafiltration step, the ultrafiltration solution is 9.5mM phosphate buffer, and the pH value is 7.1;

[0044] 9. Ion-exchange column chromatogra...

Embodiment 2

[0050] Example 2 A nano-membrane filtration method for anti-sea snake venom

[0051] Proceed as follows:

[0052] One, according to the present invention figure 1 In the technical process, the preparation of anti-sea snake venom chromatography flow-through solution specifically includes the following steps;

[0053] 1. Obtain plasma;

[0054] 2. Pepsin digestion (pH4.0);

[0055] 3. The first precipitation of ammonium sulfate (the concentration of ammonium sulfate is 15% (w / v));

[0056] 4. The second precipitation of ammonium sulfate (the concentration of ammonium sulfate is 40% (w / v));

[0057] 5. Plate and frame filter press;

[0058] 6. Alum adsorption (alum concentration is 10% (w / v));

[0059] 7. Plate and frame filter press;

[0060] 8. Concentrate and desalt the supernatant by ultrafiltration; in this ultrafiltration step, the ultrafiltration solution is 9.5mM phosphate buffer, and the pH value is 7.1;

[0061] 9. Ion-exchange column chromatography; in this chr...

Embodiment 3

[0067] Example 3 A nano-membrane filtration method for anti-sea snake venom

[0068] Proceed as follows:

[0069] One, according to the present invention figure 1 In the technical process, the preparation of anti-sea snake venom chromatography flow-through solution specifically includes the following steps;

[0070] 1. Obtain plasma;

[0071] 2. Pepsin digestion (pH3.0);

[0072] 3. The first precipitation of ammonium sulfate (the concentration of ammonium sulfate is 3% (w / v));

[0073] 4. The second precipitation of ammonium sulfate (the concentration of ammonium sulfate is 20% (w / v));

[0074] 5. Plate and frame filter press;

[0075] 6. Alum adsorption (alum concentration is 0.2% (w / v));

[0076] 7. Plate and frame filter press;

[0077] 8. Concentrate and desalt the supernatant by ultrafiltration; in this ultrafiltration step, the ultrafiltration solution is 9.5mM phosphate buffer, and the pH value is 7.1;

[0078] 9. Ion-exchange column chromatography; in this chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com