Composite heater assembly and preparation method thereof

A heater and component technology, which is applied in the field of composite heater assemblies and their preparation, can solve the problems of insufficient thermal efficiency, high working temperature of the heater, low heating efficiency, etc., achieves efficiency without magnetic field, increases resistivity, and improves thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

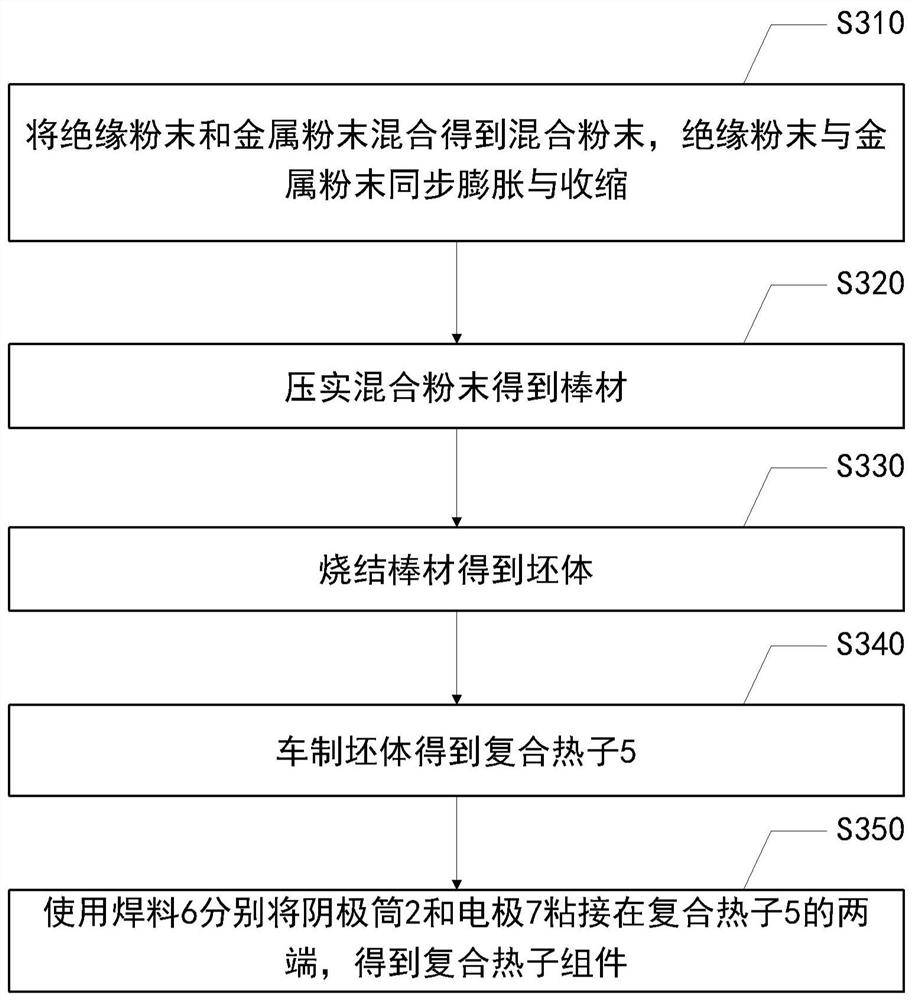

[0042] According to an embodiment of the present disclosure, such as image 3 As shown, the preparation method of composite thermal subassembly includes, for example:

[0043] S310, mixing the insulating powder and the metal powder to obtain a mixed powder, wherein the insulating powder and the metal powder expand and contract synchronously.

[0044] According to the embodiment of the present disclosure, the expansion coefficient of the insulating powder material is similar to that of the metal powder material. Therefore, during the preparation and use of the composite thermal subassembly, the structure of the composite thermal subassembly 5 is stable and will not be damaged due to thermal expansion and cooling contraction. Create defects within the material. The insulating material can be aluminum oxide, beryllium oxide, boron nitride or aluminum nitride, etc., and the metal material can be metal powder such as tungsten, rhenium or molybdenum or any mixed metal powder. Alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com