Foam carbon-based solid amine adsorbent as well as preparation method and application thereof

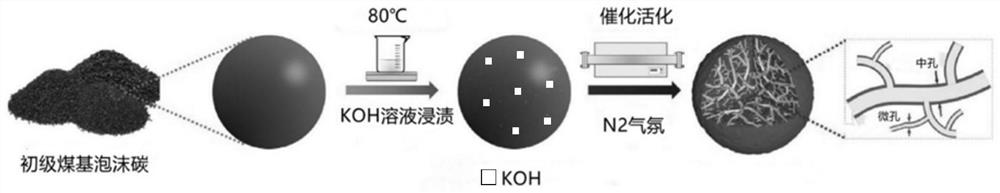

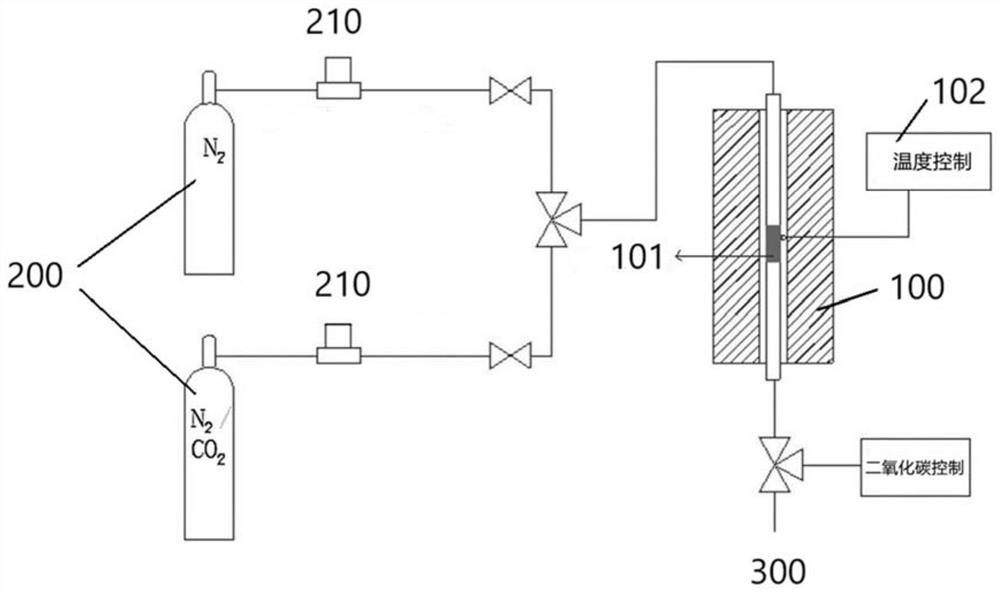

A foam carbon and solid amine technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of inability to capture carbon dioxide efficiently and cannot be effectively loaded, and achieve excellent carbon dioxide adsorption performance and regeneration capacity, increase Kinetic barrier, effect of mass transfer rate enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] A method of preparation of a foam-based solid anamine adsorbent, including the following steps:

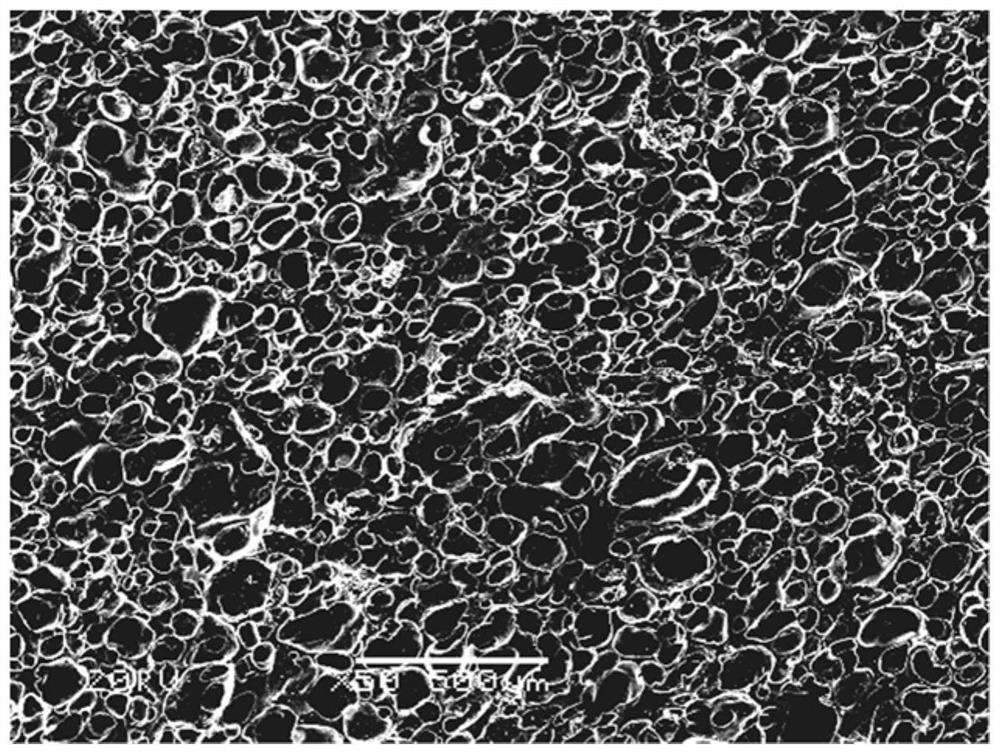

[0099] 1. Put 100 g of coal mirror enrichment (CV) in a metal mold, injected into 50 ml of toluene, and then place the metal mold in a high pressure reactor. Torn at 5 ° C / min to 480 ° C. Maintaining the final foaming pressure of 8 MPa is constant, and the constant temperature is 60 min under the supercritical conditions of toluene. After the constant temperature, it is discharged to normal pressure at a speed of 4 MPa / min, and the air valve is turned off, and the temperature is warmed to 550 ° C, temperature is 20 min, naturally cooling to room temperature to obtain primary coal base foam. The primary coal-based foam carbon is transferred to the tube furnace for carbonization treatment, under the protection of high purity nitrogen, temperature above 1000 ° C, constant temperature 120min, then naturally cooling to room temperature to obtain coal-based foam (CVCF) ), Porous ...

Embodiment 2

[0104] A method of preparation of a foam-based solid anamine adsorbent, including the following steps:

[0105] 1. Put 100 g of gas coal mirror enrichment (GV) into a metal mold, and 100 ml of toluene is injected, and then the metal mold is placed in a high pressure reactor. Torn at 5 ° C / min to 480 ° C. Maintaining the final foaming pressure of 8 MPa is constant, and the constant temperature is 60 min under the supercritical conditions of toluene. After the constant temperature, it is discharged to normal pressure at a speed of 4 MPa / min, and the air valve is turned off, and the temperature is warmed to 550 ° C, temperature is 20 min, naturally cooling to room temperature to obtain primary coal base foam. The primary coal-based foam carbon is transferred to the tube furnace for carbonization treatment, under the protection of high purity nitrogen, temperature above 1000 ° C, temperature temperature 120min, then naturally cooling to room temperature to obtain coal-based foam (...

Embodiment 3

[0110] A method of preparation of a foam-based solid anamine adsorbent, including the following steps:

[0111] 1. Mix 50 g of gas coal mirror enrichment (GV) and 50 g of coal mirror group enrichment (CV) is mixed into the metal mold, inject 100 ml of toluene, then place the metal mold in the high pressure reactor middle. Torn at 5 ° C / min to 480 ° C. Maintaining the final foaming pressure of 8 MPa is constant, and the constant temperature is 60 min under the supercritical conditions of toluene. After the constant temperature, it is discharged to normal pressure at a speed of 4 MPa / min, and the air valve is turned off, and the temperature is warmed to 550 ° C, temperature is 20 min, naturally cooling to room temperature to obtain primary coal base foam. The primary coal-based foam carbon is transferred to the tube furnace for carbonization treatment, under the protection of high purity nitrogen, temperature above 1000 ° C, temperature temperature 120min, then naturally cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com