Preparation method of modified biological calcium carbonate rubber outsole

A bio-calcium carbonate, modified technology, used in shoe soles, applications, clothing and other directions, can solve the problems of wear resistance and anti-skid performance can not meet high requirements, heavy weight and other problems, achieve good bonding performance, improve dispersibility, enhance phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

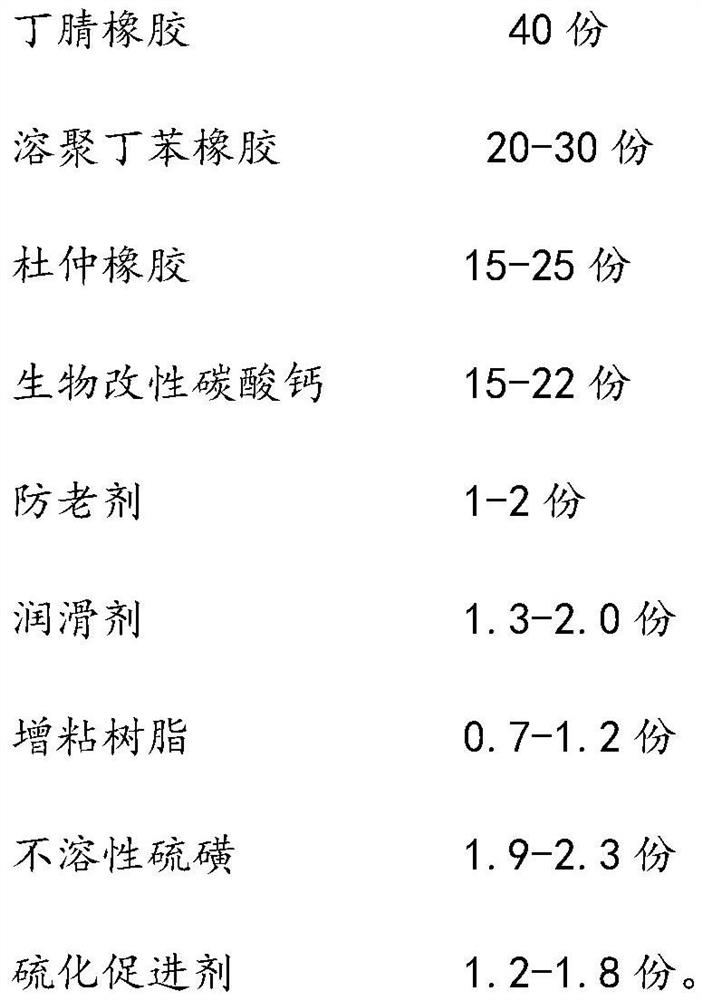

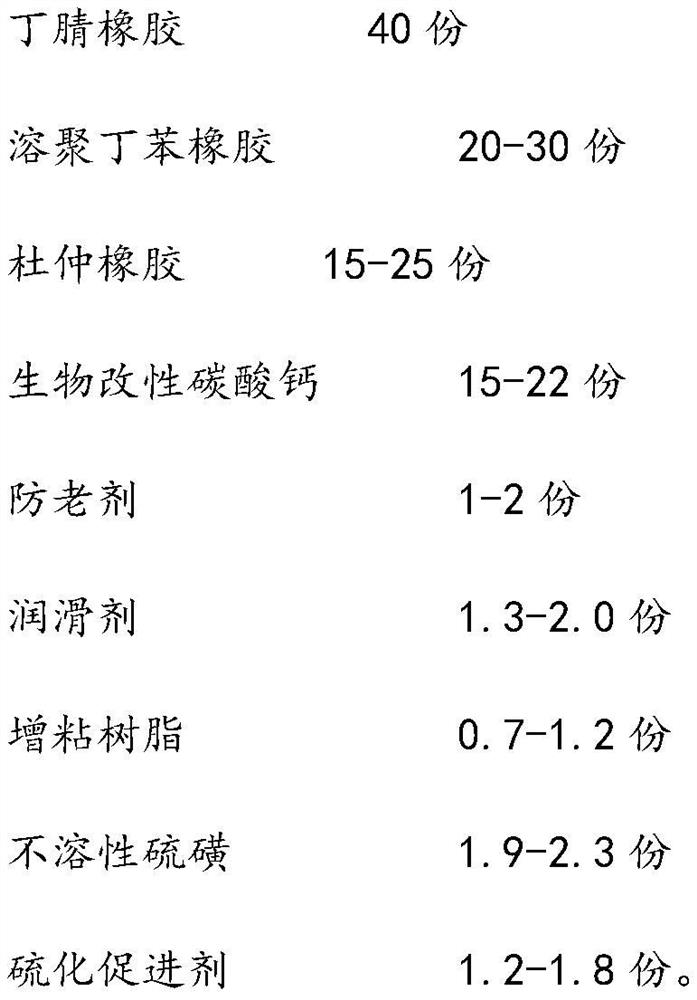

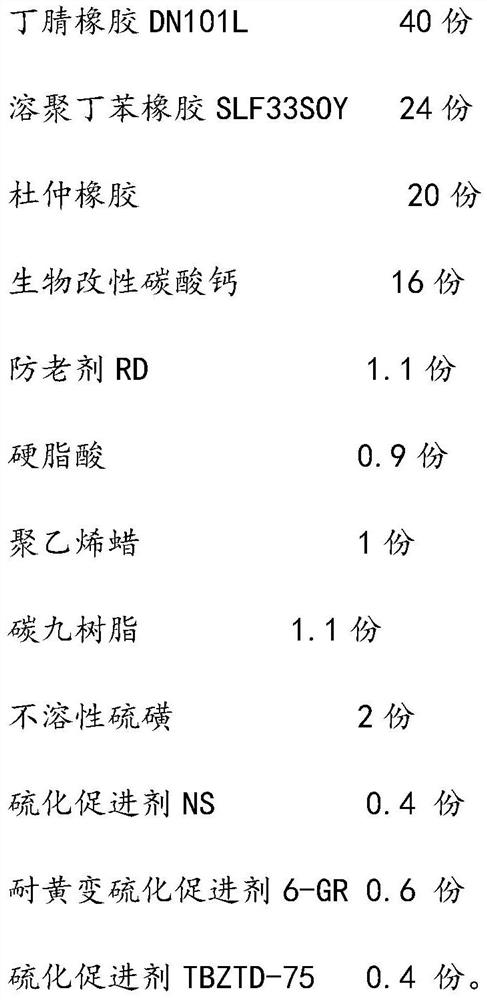

[0036] A modified bio-calcium carbonate rubber outsole in this embodiment consists of the following components in parts by mass:

[0037]

[0038] Wherein said solution polystyrene-butadiene rubber has Mooney viscosity ML (1+4) 60 (100 ℃); Comprise epoxy soybean oil 17%, styrene 33%; Vinyl 34%% (vinyl accounts for butadiene total The mass ratio of the amount); Nitrile rubber has a Mooney viscosity ML (1+4) 60 (100 ° C), and the combined acrylonitrile 42.5%; Eucommia rubber has a Mooney viscosity ML (1+4) of 40-75 at 100 ° C 4).

[0039] The modified biological calcium carbonate is biological calcium carbonate powder modified by mussel mucin extract, the particle size of the biological calcium carbonate powder is 100-300 μm, and mussel mucin is attached to the outside, and the preparation method is as follows:

[0040] ①Taking fresh mussels, kneading, cleaning, and extracting the shredded mussels to obtain the shredded mussels, and then separating the shell and meat to obta...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is: further extraction on the basis of step 1) crude extract solution to prepare fine extract solution;

[0047]Add twice the volume of acetone (-85°C) dropwise to the crude extract solution, let it stand for half an hour and then centrifuge, take the precipitate and dissolve it in 5% glacial acetic acid, and centrifuge again to get the supernatant, which is the fine extract solution .

Embodiment 3

[0049] The difference between embodiment 3 and embodiment 1 is:

[0050] A modified bio-calcium carbonate rubber outsole in this embodiment consists of the following components in parts by mass:

[0051] 40 parts of nitrile rubber DN3350, 20 parts of solution-polymerized styrene-butadiene rubber, 25 parts of Eucommia rubber, 22 parts of bio-modified calcium carbonate, 2 parts of anti-aging agent BHT, 1.2 parts of stearic acid, 0.8 parts of polyethylene wax, 1.2 parts of carbon nine resin parts, 2.3 parts of insoluble sulfur, 0.9 parts of vulcanization accelerator NS, and 0.9 parts of vulcanization accelerator TBZTD-75.

[0052] Described solution polystyrene-butadiene rubber has Mooney viscosity ML (1+4) 55 (100 ℃); Comprise epoxy soybean oil 30%, styrene 25%%; Vinyl 38% (vinyl accounts for butadiene total amount mass ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com