Preparation method of radiation refrigeration functional fabric

A functional fabric and radiant cooling technology, applied in fabrics, knitting, textiles, etc., can solve the problems of limited improvement effect and increased cost, and achieve the effect of reducing heat intake, improving reflectivity, and solving single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 15g PAN and 10g PVDF, add 100mL DMF solvent, dissolve the polymer under heating at 80°C, then add 2.5g Al 2 o 3 , with an average size of 300nm, stirred until the solution is uniform and stable;

[0036] (2) Put the polymer into a 100mL syringe, choose a 20G needle; choose a water bath with a length of 1.5 meters, a depth of 25 centimeters, and a temperature of 10°C. Adjust the moving speed of the syringe pump and the rotating speed of the coil to control the uniformity of the yarn. After the yarn is dried at 85°C, it is wound into rolls to complete the wet spinning.

[0037] (3) Using commercially available cotton thread as the weft thread and the yarn obtained by wet spinning as the warp thread, a unidirectional moisture-wicking fabric is prepared by knitting.

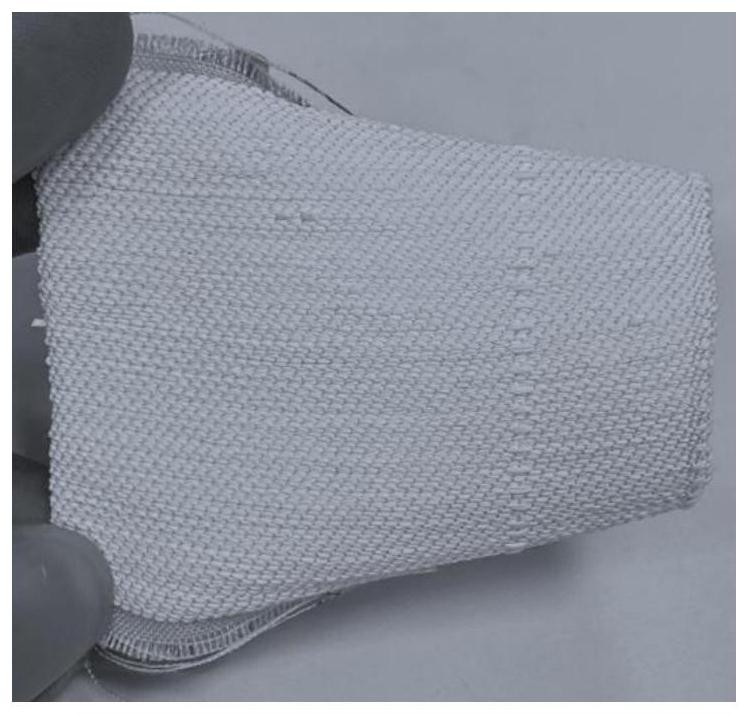

[0038] figure 1 is a frontal picture of a fabric with radiative cooling, figure 2 is its opposite picture. The front side shows white facing the external environment, and the back side has the ...

Embodiment 2

[0043] (1) Weigh 2.5g PAN and 45g PVDF, add 500mL DMSO solvent, dissolve the polymer under heating at 90°C, then add 2.5g TiO 2 , with an average size of 200nm, stirred until the solution is uniform and stable;

[0044] (2) Put the polymer into a 100mL syringe, select a 24G needle; select a coagulation bath with a length of 5 meters, a solvent of ethanol, a depth of 25 cm, and a coagulation bath temperature of 20°C. Adjust the moving speed of the syringe pump and the rotating speed of the coil to control the uniformity of the yarn. After the yarn is dried at 85°C, it is wound into rolls to complete the wet spinning.

[0045] (3) Using commercially available cotton thread as the weft thread and the yarn obtained by wet spinning as the warp thread, a unidirectional moisture-wicking fabric is prepared by knitting.

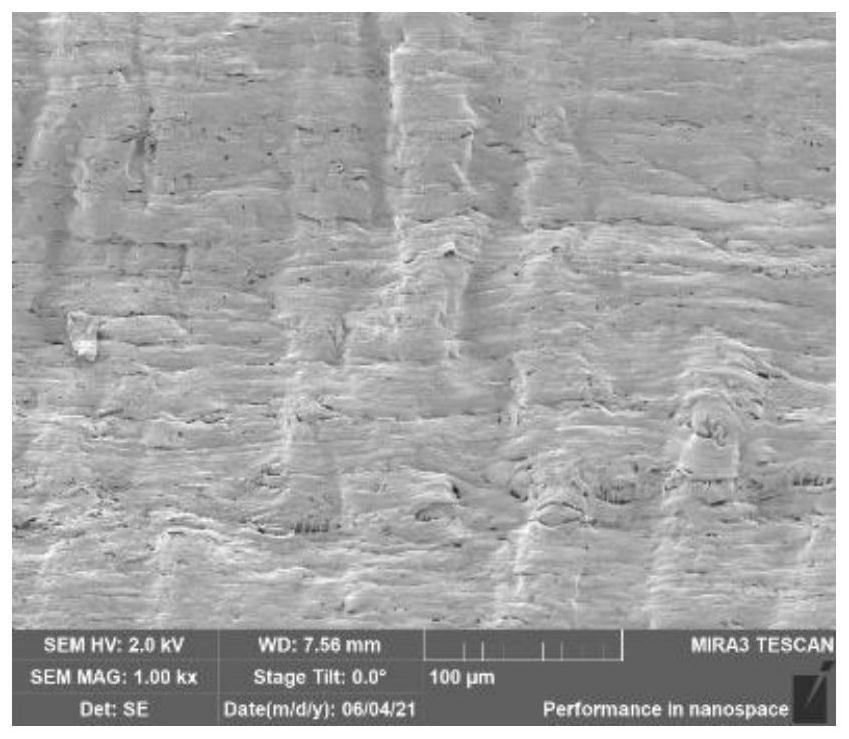

[0046] Figure 10 is a cross-sectional view of the yarn, which has pores of micro-nano structure size inside.

[0047] Figure 11 is the visible-near-infrared reg...

Embodiment 3

[0049] (1) Weigh 0.5g polystyrene and 45g PA (polyamide), add 500mL DMF solvent, dissolve the polymer under heating at 80°C, then add 3.5g TiO 2 , with an average size of 300nm and stirred until the solution is uniform and stable;

[0050] (2) Put the polymer into a 100mL syringe, choose a 24G needle; choose a coagulation bath with a length of 0.5 meters, choose isopropanol as a solvent, and use a temperature of 30° C. and a depth of 25 centimeters. Adjust the moving speed of the syringe pump and the rotating speed of the coil to control the uniformity of the yarn. After the yarn is dried at 85°C, it is wound into rolls to complete the wet spinning.

[0051] (3) Using commercially available cotton thread as the weft thread and the yarn obtained by wet spinning as the warp thread, a unidirectional moisture-wicking fabric is prepared by knitting.

[0052] Figure 12 is a cross-sectional view of the yarn, which has pores of micro-nano structure size inside.

[0053] Figure 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com