Implantable cyanoacrylate medical adhesive and application thereof

A technology of cyanoacrylate and n-butyl cyanoacrylate, which is applied in the field of implantable cyanoacrylate medical adhesives, can solve the problem of poor stability of α-butyl cyanoacrylate, safety of cracking additives, and flexibility Poor performance and other problems, to achieve the effect of controllable curing speed, prolonging the curing time, and curing and forming a soft film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Composition: 37g of n-butyl α-cyanoacrylate, 12g of plasticizer tributyl citrate, 226mg of hydroquinone as a polymerization inhibitor, 2g of polyethylene glycol 400 as a toughening agent, and 706mg of p-toluenesulfonic acid as a stabilizer. Accurately weigh the above-mentioned substances, mix and sterilize evenly by stirring to obtain the medical glue of the present invention. Existing commercially available medical adhesive A combination: the main component is n-butyl α-cyanoacrylate, the plasticizer is dioctyl phthalate, the polymerization inhibitor is sulfur dioxide, and the stabilizer is p-toluenesulfonic acid.

experiment example

[0043] Cure speed test:

[0044] Method: Add 80ml of 0.3g / L sodium bicarbonate solution to a plate with a diameter of 140mm, absorb the medical glue with a dropper, drop a drop at a place 5cm above the liquid surface, and record the curing time of the glue.

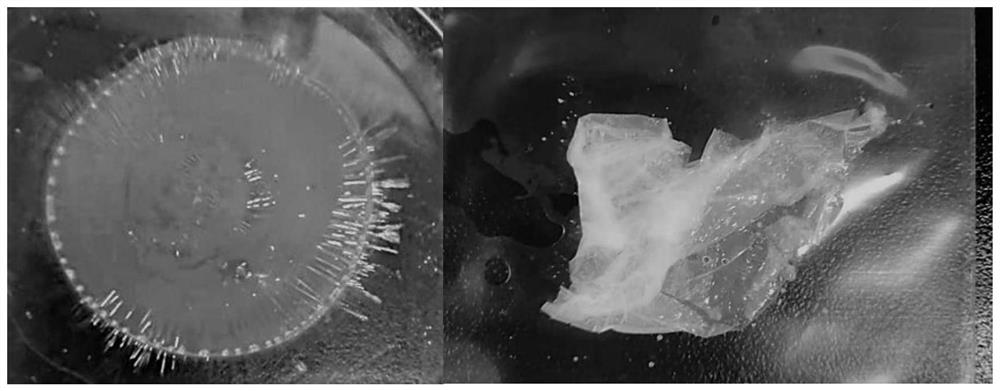

[0045] Data: The curing time of the medical adhesive in this case is 15s, and the cured film is soft and not easy to break ( figure 1 ), there is no foreign body when it is lifted and bent, indicating that the patient's foreign body sensation is weakened after implantation. In the comparison experiment, the polymerization inhibitor used in the existing commercially available A medical adhesive is sulfur dioxide, and its curing time is 6-8s, and the cured film is easy to break ( figure 2 ), the bending part is hard and has a foreign body feeling.

[0046] Curing Exotherm Test:

[0047] Method: α-cyanoacrylate medical glue should release heat while curing. When the heat release is the highest, the local tissue will feel...

Embodiment 2 Embodiment 6

[0060] The following table 2 is used to prepare according to the method of Example 1, wherein the plasticizers used in Examples 2 to 6 are tributyl citrate, acetyl tributyl citrate, triethyl citrate, and acetyl tributyl citrate , triethyl citrate, the polymerization inhibitor glacial acetic acid used in embodiment three, all the other material types are identical with embodiment 1.

[0061] Table 2: Components and performance test results of Embodiment 2 to Embodiment 6

[0062]

[0063]

[0064] performance test results

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com