Method for preparing membrane material by using activated aluminum oxide

A technology of activated alumina and membrane materials, applied in the field of membrane materials, can solve the problems of affecting the application, difficult to process and form, and the inorganic membrane is inelastic, and achieve the effects of improving wettability, lowering melting point, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

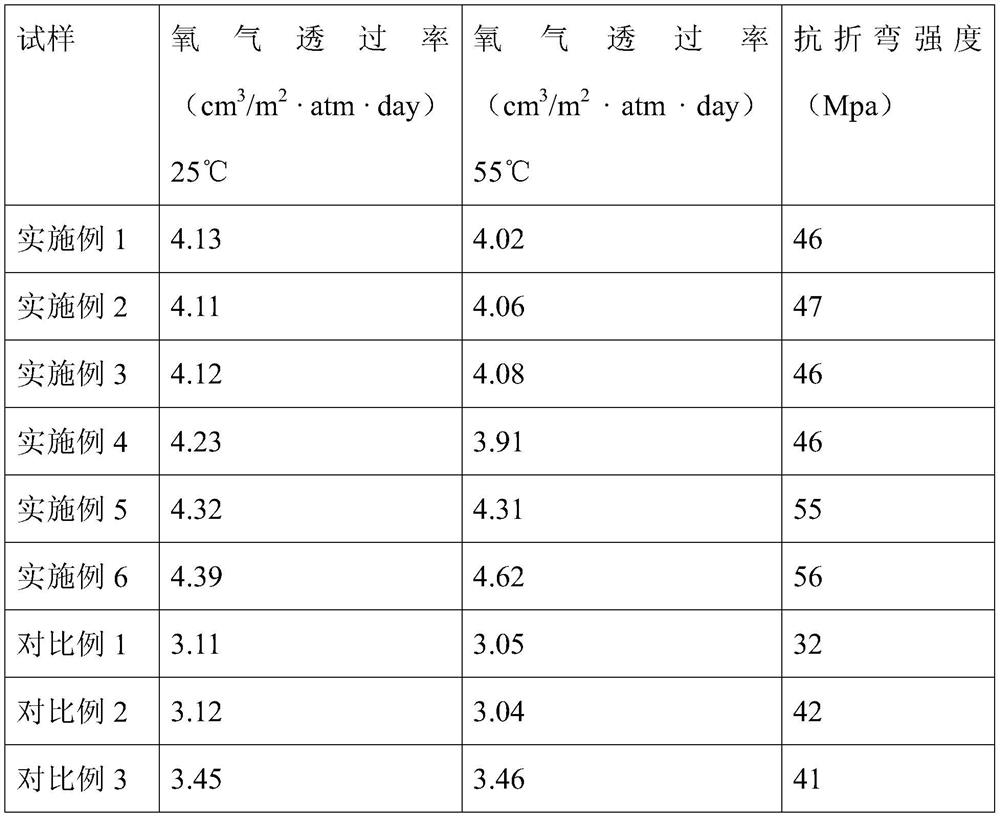

Examples

Embodiment 1

[0022] Mix 80 parts of pseudoboehmite, 7 parts of titanium oxide micropowder, 2 parts of tourmaline powder, part of nano-magnesia and 9 parts of kaolin according to parts by weight, wherein the powder particles are all controlled between 0.1-0.5 μm, add water Make a slurry, add 4% rare earth material (yttrium oxide) accounting for the mass of the slurry, mix evenly, continue to add organic additives accounting for 5% of the mass of the slurry, and fully stir for 24 hours to prepare a mixed slurry, and coat the mixed slurry covered on the support body and sintered to obtain an inorganic membrane.

[0023] The sintering conditions are as follows: in a vacuum and nitrogen atmosphere, heat up to 900°C at a rate of 0.5°C / min, and keep it warm for 5h; , kept at 350°C for 5h, and then cooled with the furnace.

[0024] The organic additive includes a mixture of vermiculite and water-absorbing resin in a mass ratio of 1:0.5.

Embodiment 2

[0026] According to parts by weight, 85 parts of pseudoboehmite, 4 parts of titanium oxide micropowder, 3 parts of tourmaline powder, 1 part of nano-magnesia and 11 parts of kaolin were mixed evenly, and the powder particles were all controlled between 0.1-0.5 μm. Add water to make a slurry, add 3% rare earth material (yttrium oxide) accounting for the mass of the slurry, mix evenly, continue to add organic additives accounting for 6% of the mass of the slurry, and fully stir for 24 hours to prepare a mixed slurry. The mixed slurry It is coated on a support body and sintered to obtain an inorganic membrane.

[0027] The sintering conditions are as follows: in a vacuum and nitrogen atmosphere, heat up to 850°C at a rate of 0.6°C / min, and keep warm for 5h; , kept at 350°C for 5h, then cooled with the furnace;

[0028] The organic additive includes a mixture of vermiculite and water-absorbing resin in a mass ratio of 3:1.

Embodiment 3

[0030] According to parts by weight, 87 parts of pseudoboehmite, 8 parts of titanium oxide micropowder, 3 parts of tourmaline powder, 5 parts of nano-magnesia and 5 parts of kaolin were uniformly mixed, and the powder particles were all controlled between 0.1-0.5 μm. Add water to make a slurry, add 3% rare earth material (yttrium oxide) accounting for the mass of the slurry, mix evenly, continue to add organic additives accounting for 4% of the mass of the slurry, and fully stir for 24 hours to prepare a mixed slurry. It is coated on a support body and sintered to obtain an inorganic membrane.

[0031] The sintering conditions are as follows: in a vacuum and nitrogen atmosphere, heat up to 900°C at a rate of 1°C / min, and keep warm for 4h; , kept at 350°C for 5h, and then cooled with the furnace.

[0032] The organic additive includes a mixture of vermiculite and water-absorbing resin in a mass ratio of 1:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com