Gradient concrete material with small bending deformation and preparation method thereof

A technology of concrete and cement concrete, applied in the field of cement-based materials, can solve the problems of increasing the risk of shrinkage cracking, increasing the load-bearing pressure of the structure, increasing the carbon emission, etc., to increase flexibility, improve the ability of tensile deformation, and improve the integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

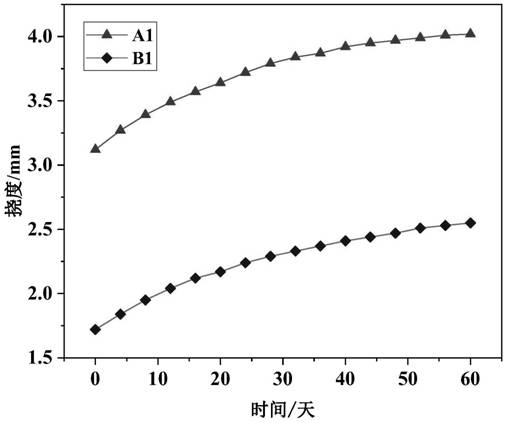

[0024] First, two groups of C30 strength concrete beams with a length of 1200 mm, a width of 120 mm, and a height of 250 mm were fabricated. The first group was a beam without performance-adjusting materials, which was recorded as group A1. The other group is prepared according to the method proposed by the present invention, and is denoted as group B1. The amount of required materials is: Group A1: selected according to "Ordinary Concrete Mix Proportion Design Regulations" JGJ552011; Group B1: In addition to conventional raw materials selected according to "Ordinary Concrete Mix Proportion Design Regulations" JGJ552011, performance adjustment materials are selected within the diameter range 0.036kg of titanium dioxide nanotubes with a diameter of 10-20nm and a length of 0.8-2μm, 0.1kg of nano-silicon dioxide particles with a particle size range of 20-30nm, a cobalt / carbon nanofiber composite material with a diameter of 25-40nm and a length of 10-20μm 0.0324 kg, 0.019 kg of ca...

Embodiment 2

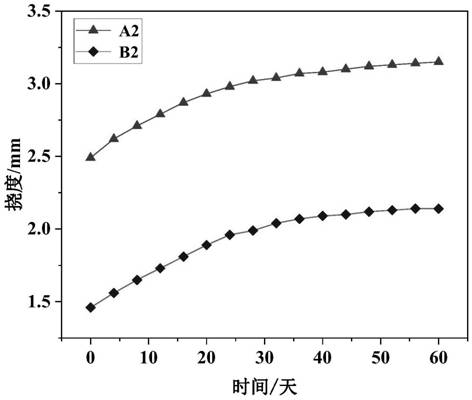

[0027] First, two groups of C50 strength concrete beams with a length of 1600 mm, a width of 150 mm, and a height of 300 mm are made. The first group is a beam without performance-adjusting materials, which is recorded as group A2. Another group prepared according to the method proposed by the present invention is denoted as group B2. The amount of required materials is: Group A2: selected according to "Ordinary Concrete Mix Proportion Design Regulations" JGJ552011; Group B2: In addition to conventional raw materials selected according to "Ordinary Concrete Mix Proportion Design Regulations" JGJ552011, the diameter range is 10-20nm , 0.072kg of titanium dioxide nanotubes with a length of 0.8-2μm, 0.216kg of nano-silica particles with a particle size range of 20-30nm, 0.068kg of cobalt / carbon nanofiber composites with a diameter of 25-40nm, and a length of 10-20μm. 0.043kg of carbon nanofibers with a length of 150-200nm and a length of 10-15μm, 0.252kg of neoprene rubber, 0.52k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com