Complex-phase sodium storage positive electrode material as well as preparation method and application thereof

A cathode material and layered technology, applied in the field of composite cathode materials and their preparation, can solve the problems of unsatisfactory stability, low capacity and high phase capacity, improve structural stability and cycle performance, reduce reaction temperature, improve The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

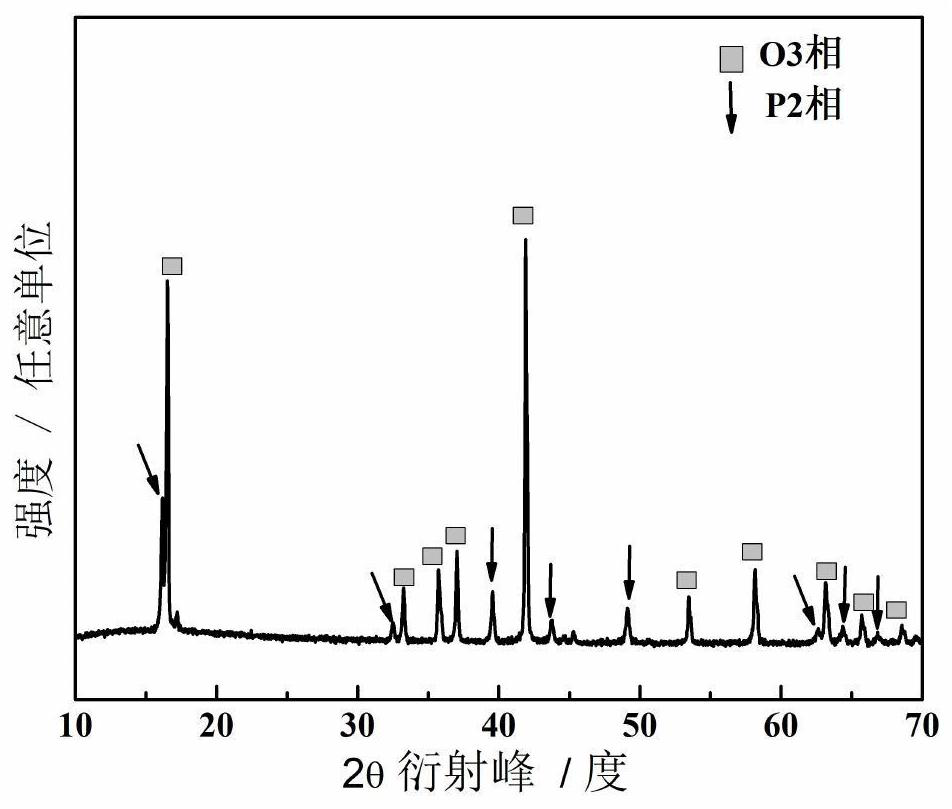

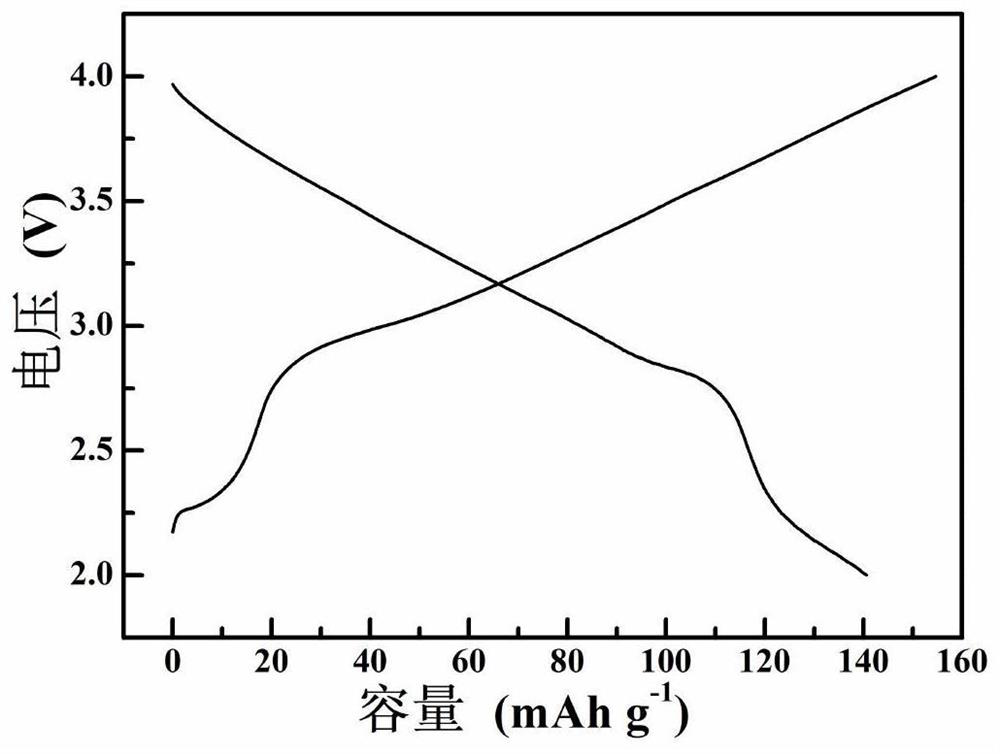

[0030] Press Na[Li 0.05 (Ni 0.25 Fe 0.25 mn 0.5 ) 0.95 ]O 2 Stoichiometric ratio, weighed Na 2 CO 3 , Li 2 CO 3 , NiO, Fe 2 o 3 , Mn 2 o 3 Mix evenly by ball milling, press into tablets at 1MPa; then pre-fire at 400°C in air atmosphere for 3 hours, cool to room temperature and then grind and pulverize; then press at 1MPa, and then bake at 850°C in air atmosphere for 15 hours , and then naturally cooled to room temperature. The product is analyzed by XRD and has P2 and O3 composite phases, see figure 1 . The material prepared in this embodiment is used as the positive electrode, the sodium metal is used as the negative electrode, the glass fiber is used as the separator, and NaPF 6 The propylene carbonate (PC) / ethyl methyl carbonate (EMC) solution is the electrolyte, and the fluorinated ethylene carbonate (FEC) that the weight of the above electrolyte is 3% is added, the button battery is assembled, and the charge and discharge test is carried out. The current de...

Embodiment 2

[0040] Press Na[Li 0.03(Ni 0.20 Fe 0.35 mn 0.45 ) 0.97 ]O 2 Stoichiometric ratio, weighed Na 2 CO 3 , Li 2 CO 3 , NiO, Fe 2 o 3 , Mn 2 o 3 Mix evenly by ball milling, press into tablets at 1MPa; then pre-calcine in air at 400°C for 3 hours, cool down to room temperature, grind and pulverize, then press at 1MPa; then bake in air at 830°C for 15 hours , and then naturally cooled to room temperature. According to XRD analysis, the product has a composite phase of P2 and O3. The above product was electrochemically tested according to the method of Example 1, and the initial discharge capacity of the product could reach 143mAh / g.

Embodiment 3

[0042] Press Na[Li 0.04 (Ni 0.35 Fe 0.25 mn 0.4 ) 0.96 ]O 2 The stoichiometric ratio, weighed Na 2 CO 3 , Li 2 CO 3 , NiO, Fe 2 o 3 , Mn 2 o 3 Mix evenly through ball milling, press into tablets at 1MPa; then pre-calcine in air at 400°C for 3 hours, cool to room temperature, grind and pulverize, then press at 1MPa; then bake in air at 860°C for 15 hours , and then naturally cooled to room temperature. According to XRD analysis, the product has a composite phase of P2 and O3. The above product was electrochemically tested according to the method of Example 1, and the initial discharge capacity of the product could reach 140mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge capacity | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com