Process method suitable for low-carbon-nitrogen-ratio sewage treatment

A process method and technology for sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc., which can solve the problems of inconvenient operation, substandard effluent, and poor denitrification effect. , to achieve the effect of reducing the number of structures and the land area of the sewage treatment plant, reducing the consumption of organic matter, and reducing the cost of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

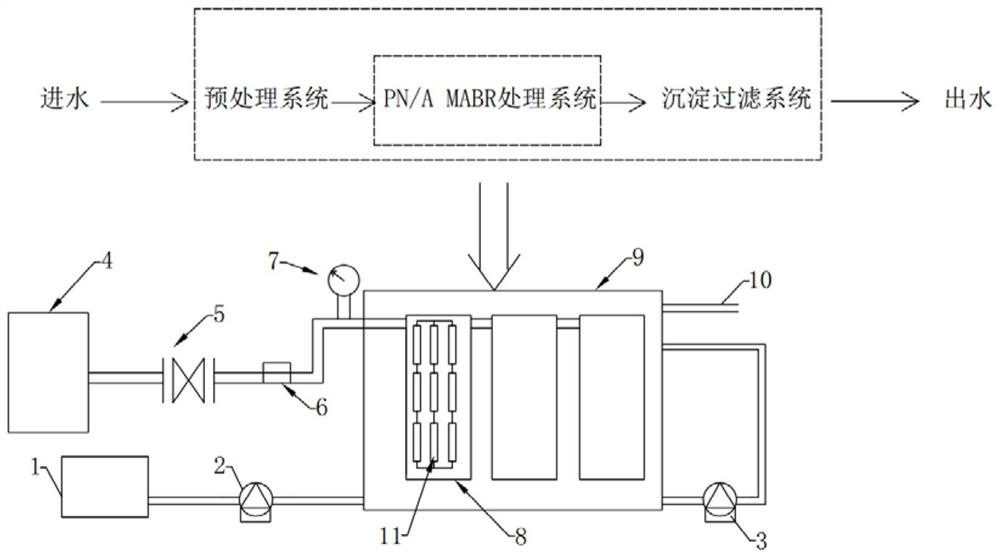

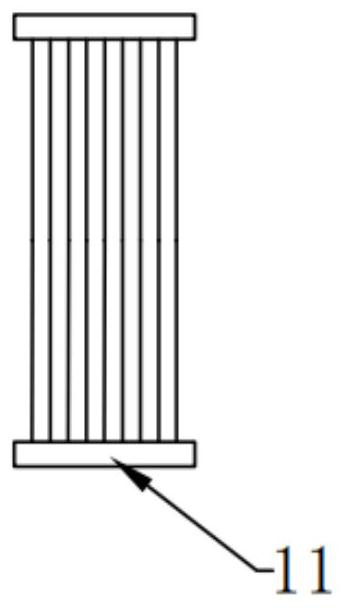

[0042] Example 1: The test device system includes water inlet tank 1, water inlet pump 2, circulation pump 3, air supply equipment 4, regulating valve 5, flow meter 6, pressure gauge 7, integrated membrane block 8, MABR membrane system 9 and outlet pipe 10. A group of integrated membrane blocks 8 are installed in the MABR membrane system 9. The integrated membrane blocks 8 contain MABR membrane components 11 and exhaust valves. The integrated membrane blocks 8 are connected to the gas supply equipment 4 and its auxiliary facilities, and the gas supply equipment 4 is turned on; Take the activated sludge from the aeration tank of the urban sewage treatment plant, add it to the MABR membrane system 9, and use the method of regularly adding ammonia nitrogen and COD to continue the operation, so that the microorganisms are loaded on the surface of the MABR membrane; Nitrate accumulation rate and dissolved oxygen were inoculated with anammox activated sludge, and the circulation pump...

Embodiment 2

[0043] Example 2: 5 MABR modules are implanted in a sewage treatment pool with a low nitrogen removal ratio; according to the above steps, the influent is gradually adjusted to be sewage, the carbon-nitrogen ratio of the influent is less than 1, and the ammonia nitrogen removal efficiency can reach more than 90.81%. The treatment load was 247.15mg N / (L·d).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com