Aluminum alloy surface protection method based on visible light laser absorption and application

A technology of aluminum alloy surface and laser absorption, which is applied in the field of metallurgy, can solve the problems of insufficient bonding force, coating peeling off, low efficiency, etc., and achieve the effects of reducing reflection, increasing service life, and reducing burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

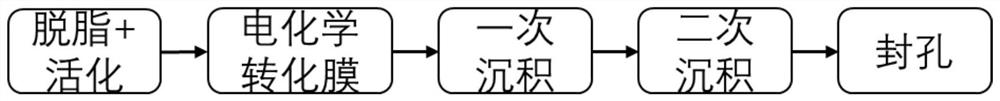

[0047] Such as figure 1 As shown in the flow chart, the method for protecting the surface of aluminum alloy based on visible light laser absorption described in this embodiment includes the following steps:

[0048] (1) Soak the processed aluminum alloy parts in the degreasing solution with an ultrasonic cleaning device, take them out and put them in an alkali etching tank to remove the oxide film, and finally remove the "ash" produced in the alkali etching step through a neutralization tank to remove the test material. parts surface grease and natural oxide film; the bath composition and operating parameters of each step of the pretreatment are shown in Table 2 below:

[0049] Table 2 pretreatment process parameters

[0050]

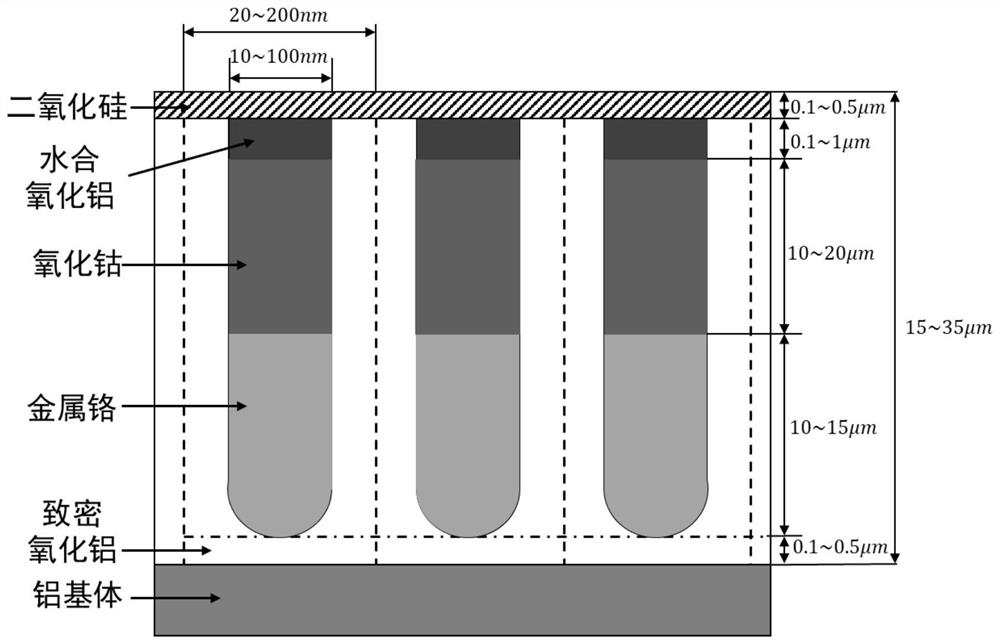

[0051] (2) In a 12wt% sulfuric acid solution, the aluminum alloy workpiece is anodized in the form of direct current, the temperature of the solution is controlled at 5°C, and the control voltage is gradually increased from 12V to 20V for about 1 hour...

Embodiment 2

[0059] Such as figure 1 As shown in the flow chart, the method for protecting the surface of aluminum alloy based on visible light laser absorption described in this embodiment includes the following steps:

[0060] (1) Soak the processed aluminum alloy parts in the degreasing solution with an ultrasonic cleaning device, take them out and put them in an alkali etching tank to remove the oxide film, and finally remove the "ash" produced in the alkali etching step through a neutralization tank to remove the test material. parts surface grease and natural oxide film; the bath composition and operating parameters of each step of the pretreatment are the same as in Example 1;

[0061] (2) In a 12wt% sulfuric acid solution, the aluminum alloy workpiece is anodized in the form of direct current, the temperature of the solution is controlled at 5°C, and the control voltage is gradually increased from 12V to 20V for about 1 hour. Form a regular porous aluminum oxide layer (the pore st...

Embodiment 3

[0067] Such as figure 1 As shown in the flow chart, the method for protecting the surface of aluminum alloy based on visible light laser absorption described in this embodiment includes the following steps:

[0068] (1) Soak the processed aluminum alloy parts in the degreasing solution with an ultrasonic cleaning device, take them out and put them in an alkali etching tank to remove the oxide film, and finally remove the "ash" produced in the alkali etching step through a neutralization tank to remove the test material. parts surface grease and natural oxide film; the bath composition and operating parameters of each step of the pretreatment are the same as in Example 1;

[0069] (2) In 10wt% sulfuric acid solution, the aluminum alloy workpiece is anodized in the form of direct current, the temperature of the solution is controlled at 6°C, and the control voltage is gradually increased from 12V to 20V for about 1 hour. Form a regular porous alumina layer;

[0070] (3) Place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com