Method for determining light stabilizer UV119 in leather material

A UV119 and light stabilizer technology, applied in the testing field, can solve problems such as low solubility of organic solvents, affecting test results, complex molecular structure, etc., and achieve the effects of improving solvent permeability, improving extraction efficiency, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Instrument and reagents

[0072] Agilent 1290 super high performance liquid chromatograph, including four-dimensional pump, online vacuum degasser, column temperature box, autosampler, and diode array detector (DAD); Milli-Q type pure water system; frozen pulverizer, KQ3200DE ultrasonic cleaner.

[0073] Methanol, dichloromethane, tetrahydrofuran, dimethyl sulfoxide is HPLC stage; test water is ultrapure water. The sample solution was filtered with a 0.22 μm filter.

[0074] Comparative extract: tetrahydrofuran, dimethyl sulfoxide, dichloromethane ratio of 6: 1: 3.

[0075] 2. Chromatographic conditions

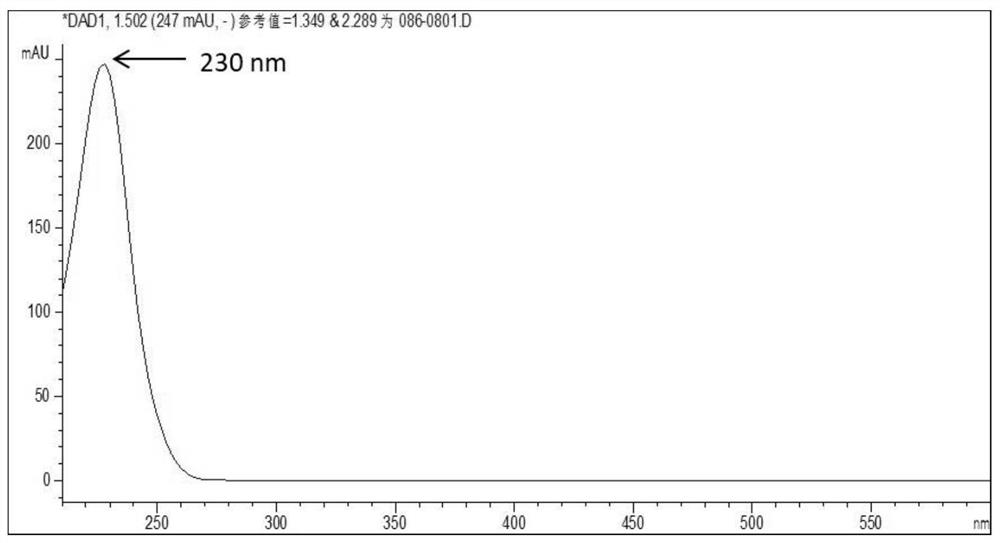

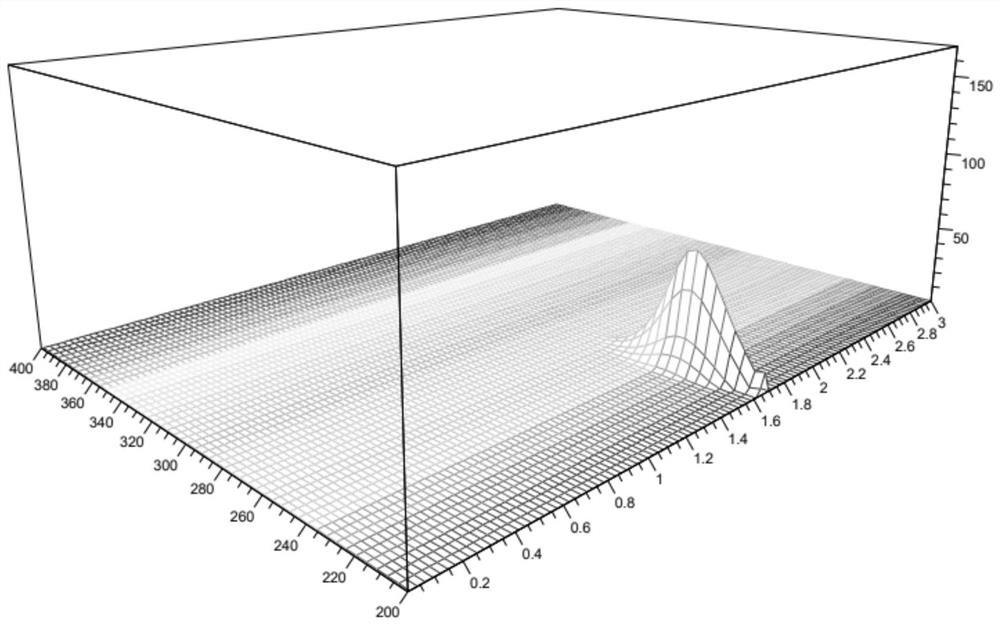

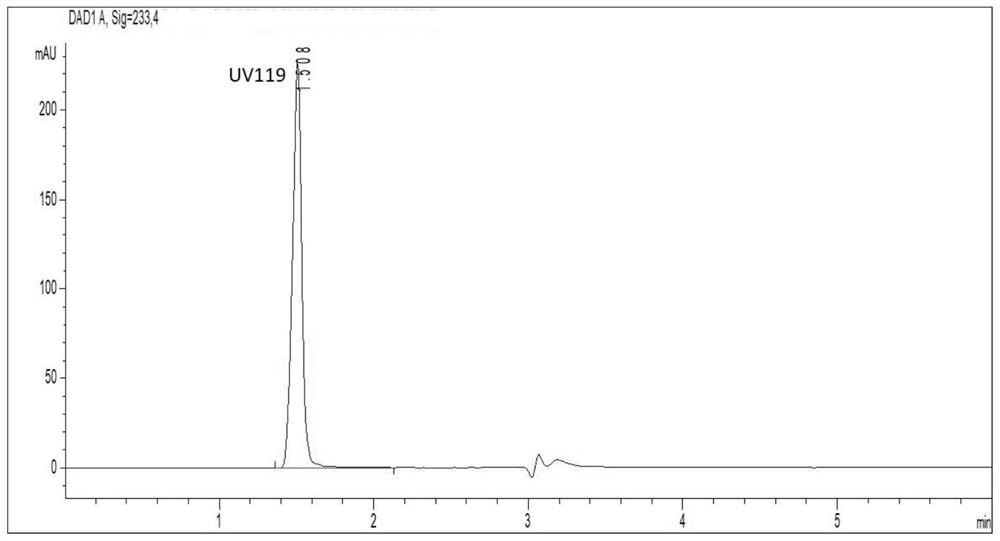

[0076] Liquid chromatography: Syncronis Amino column (100mm × 2.1mm × 1.7 μm); column temperature 35 ° C; flow rate of 0.4 ml / min; water intake is 5 μL; flow phase methanol-aqueous ammonium aqueous solution (10 mmol / L) (7) : 3 Equality); DAD detection wavelength range 180 nm-400 nm, quantitative wavelength is 230 nm.

[0077] 3. Establishment of standard working curve ...

Embodiment 2

[0088] Instrument and reagents

[0089] Agilent 1290 super high performance liquid chromatograph, including four-dimensional pump, online vacuum degasser, column temperature box, autosampler, and diode array detector (DAD); Milli-Q type pure water system; frozen pulverizer, KQ3200DE ultrasonic cleaner.

[0090] Methanol, dichloromethane, tetrahydrofuran, dimethyl sulfoxide is HPLC stage; test water is ultrapure water. The sample solution was filtered with a 0.22 μm filter.

[0091] Comparative extract: tetrahydrofuran, dimethyl sulfoxide, dichloromethane ratio of 6: 1: 3.

[0092] 2. Chromatographic conditions

[0093] Liquid chromatography: SYNCronis Amino column (100mm × 2.1mm × 1.7 μm); column temperature 35 ° C; flow rate of 0.4 ml / min; water intake is 5 μL; flow phase methanol-aqueous ammonium aqueous solution (10M mol / L) 7:3 Equality); DAD detection wavelength range 180 nm-400 nm, quantitative wavelength is 230 nm.

[0094] 3. Establishment of standard working curve

[0...

Embodiment 3

[0102] Instrument and reagents

[0103] Agilent 1290 super high performance liquid chromatograph, including four-dimensional pump, online vacuum degasser, column temperature box, autosampler, and diode array detector (DAD); Milli-Q type pure water system; frozen pulverizer, KQ3200DE ultrasonic cleaner.

[0104] Methanol, dichloromethane, tetrahydrofuran, dimethyl sulfoxide is HPLC stage; test water is ultrapure water. The sample solution was filtered with a 0.22 μm filter.

[0105] Comparative extract: tetrahydrofuran, dimethyl sulfoxide, dichloromethane ratio of 6: 1: 3.

[0106] 2. Chromatographic conditions

[0107] Liquid chromatography: SYNCronis Amino column (100mm × 2.1mm × 1.7 μm); column temperature 35 ° C; flow rate of 0.4 ml / min; water intake is 5 μL; flow phase methanol-aqueous ammonium aqueous solution (10M mol / L) 7:3 Equality); DAD detection wavelength range 180 nm-400 nm, quantitative wavelength is 230 nm.

[0108] 3. Establishment of standard working curve

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com