Flue gas desulfurization and denitrification two-phase continuous absorption system and method

A desulfurization and denitrification, two-phase continuous technology, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve the problems of slow hydrolysis rate, difficult removal, oxidant absorption, etc., achieving simple device structure, low equipment investment, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

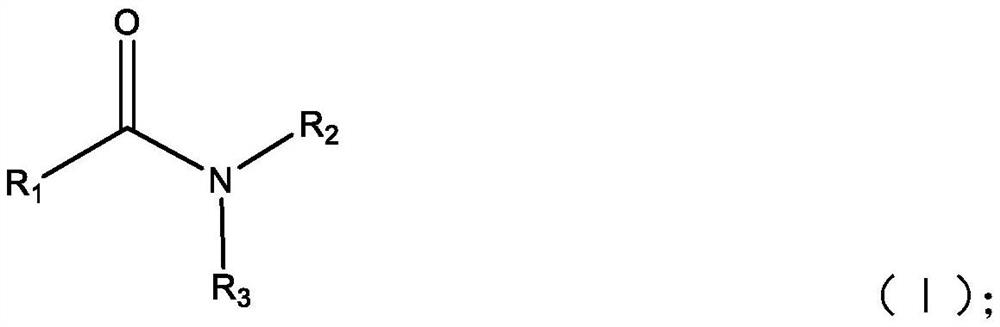

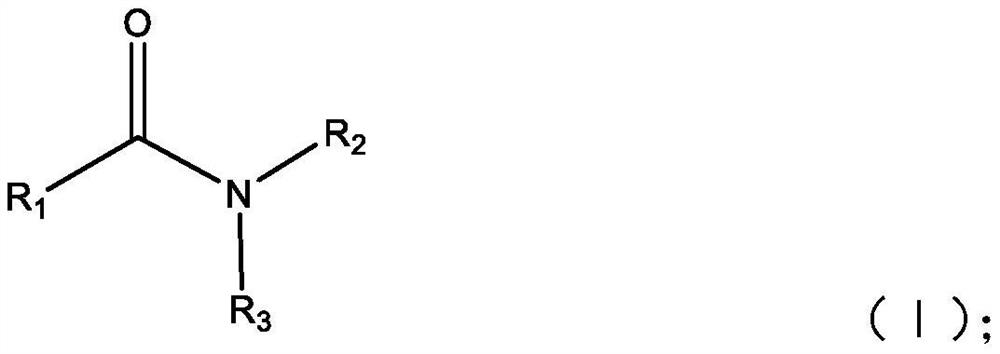

[0032] In this implementation, the flue gas desulfurization and denitrification two-phase continuous absorption system is an emulsion composed of an aqueous phase oxidant and an organic phase absorbent; the volume ratio of the aqueous phase oxidant to the organic phase absorbent is 6:3; the aqueous phase oxidant is sodium hypochlorite solution The preparation method of water-phase oxidant is: adopt metering pump to carry seawater desalination intercepted liquid to carry out reaction in the sodium hypochlorite generator, the working temperature of sodium hypochlorite generator is 20 ℃, and the sodium hypochlorite solution that reaction makes available chlorine is 10wt%; Will effectively Chlorine is that the sodium hypochlorite solution of 10wt% is diluted into available chlorine and is the sodium hypochlorite solution of 0.5wt%, and adjusts its pH to 6, promptly makes aqueous phase oxidant; Show.

[0033]

[0034] Use the above flue gas desulfurization and denitrification tw...

Embodiment 2

[0036] In this implementation, the flue gas desulfurization and denitrification two-phase continuous absorption system is an emulsion composed of an aqueous phase oxidant and an organic phase absorbent; the volume ratio of the aqueous phase oxidant to the organic phase absorbent is 8:4; the aqueous phase oxidant is sodium hypochlorite solution The preparation method of water-phase oxidant is: adopt metering pump to carry seawater desalination intercepted liquid to carry out reaction in the sodium hypochlorite generator, the working temperature of sodium hypochlorite generator is 40 ℃, and the sodium hypochlorite solution that reaction makes available chlorine is 5wt%; Will effectively The sodium hypochlorite solution that chlorine is 5wt% is diluted into the sodium hypochlorite solution that available chlorine is 1wt%, and adjusts its pH to 8, promptly makes aqueous phase oxidant; Organic phase absorbent is N, N-diphenylacetamide, and its structural formula is as follows: Shown...

Embodiment 3

[0040] In this implementation, the flue gas desulfurization and denitrification two-phase continuous absorption system is an emulsion composed of an aqueous phase oxidant and an organic phase absorbent; the volume ratio of the aqueous phase oxidant to the organic phase absorbent is 4:2; the aqueous phase oxidant is sodium hypochlorite solution The preparation method of water phase oxidant is: adopt metering pump to carry seawater desalination intercepted liquid to carry out reaction in the sodium hypochlorite generator, the working temperature of sodium hypochlorite generator is 25 ℃, and the sodium hypochlorite solution that reaction makes available chlorine is 10wt%; Will effectively Chlorine is that the sodium hypochlorite solution of 10wt% is diluted into available chlorine and is the sodium hypochlorite solution of 2wt%, and adjusts its pH to 7, promptly makes aqueous phase oxidant; Organic phase absorbent is tributylamine, and its structural formula is as shown in structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com