Laser welding method for dissimilar materials of titanium alloy and aluminum alloy

A technology of laser welding and dissimilar materials, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., it can solve the problems of complex assembly, difficult to form effective connection, laser power limitation, etc., to prevent mixing and reaction , good quality, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

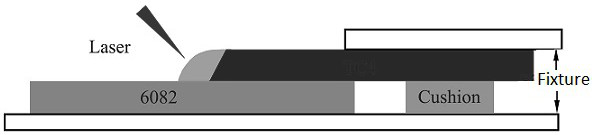

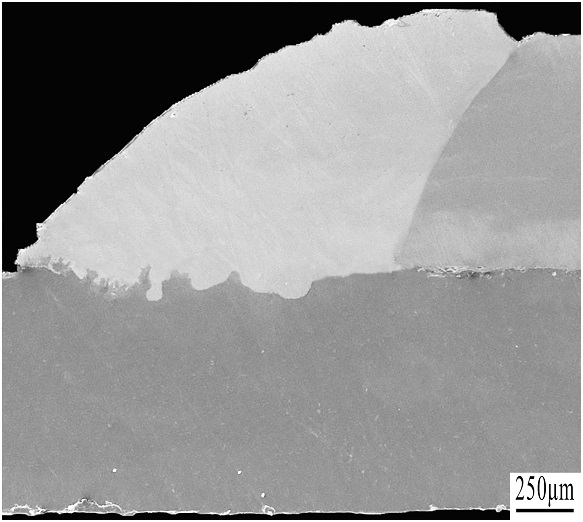

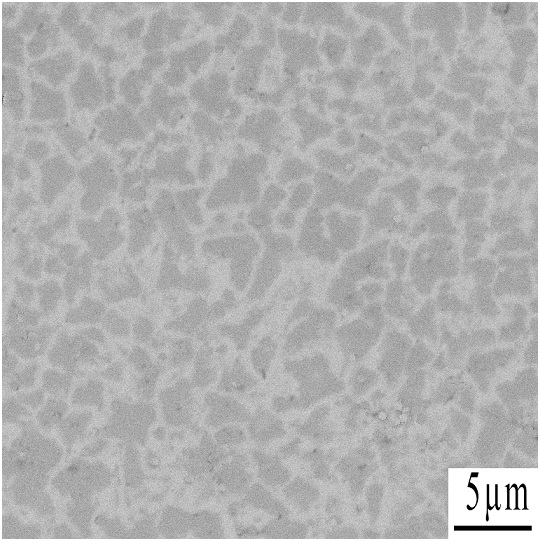

[0032] see Figure 1 to Figure 3 Shown, the laser welding method of TC4 titanium alloy of the present invention and 6082 aluminum alloy dissimilar materials comprises the steps:

[0033] Step 1. Cleaning: Before welding the workpiece to be welded, perform a cleaning operation on the workpiece to be welded to obtain the cleaned workpiece to be welded;

[0034] Step 2. Assembly: Use the welding fixture to apply clamping force on the TC4 titanium alloy metal plate and 6082 aluminum alloy plate to be welded to fix the position of the laser;

[0035] Step 3. Set welding parameters: place the assembled workpiece in the fiber laser welding room, and adjust the laser welding process parameters;

[0036]Step 4. Welding: After adjusting the welding parameters, laser welding is performed on the workpiece to be welded. After the welding is completed, the workpiece is cooled naturally, and then the workpiece is taken out.

[0037] The purpose of the present invention is to break through ...

Embodiment 2

[0043] combine figure 2 To illustrate this embodiment, the thicknesses of the TC4 titanium alloy plate and the 6082 aluminum alloy plate to be welded in step 1 of this embodiment are both 1mm. The undisclosed technical features in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0045] combine figure 2 To illustrate this embodiment, the spot diameter in step 1 of this embodiment is 1.5mm, and the laser incident angle is 40 degrees. The undisclosed technical features in this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com