Method for removing trace micromolecular organic matters in reclaimed water

A technology of reclaimed water and small molecules, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as removal rate and complex process that easily cause other problems, achieve effective removal, simple process, and overcome generation low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

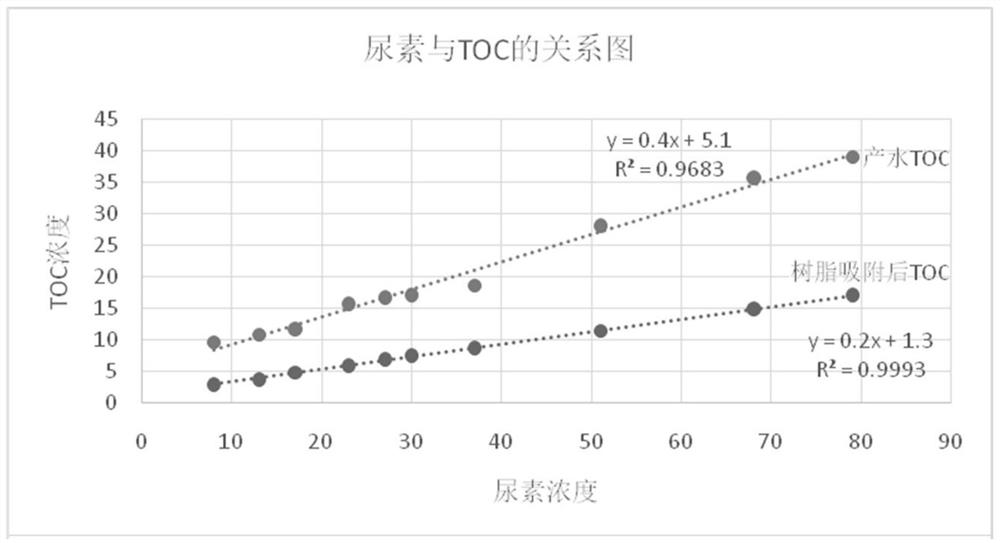

Image

Examples

Embodiment 1

[0016] The regenerated water obtained after UF+RO treatment is added with an oxidant and then passed into the ultraviolet oxidation device. The ultraviolet lamp is installed in the ultraviolet oxidation device, and the regenerated water with the oxidant is irradiated through the ultraviolet lamp. The oxidant includes the following mass fractions: Divide: 6.0% hydrogen peroxide, 42.0% peroxodisulfate, 2.0% chloramine and 50.0% water.

[0017] The concentration of urea in reclaimed water is 123ppb;

[0018] The addition amount of oxidizing agent is Y=5.1ln(123)+2.9=27.4ppm, gets 30ppm (30ppm refers to the total concentration of three active components-hydrogen peroxide, peroxodisulfate and chloramine in oxidizing agent);

[0019] The hydraulic retention time in the UV oxidation device is 120s;

[0020] The irradiation dose is Z=3.4(123) 0.8 =159.7mJ / cm 2 , take 160mJ / cm 2 ;

[0021] After testing, the TOC concentration of the product water was 16.8ppb.

[0022] Pass the pr...

Embodiment 2

[0024] The regenerated water obtained after UF+RO treatment is added with an oxidant and then passed into the ultraviolet oxidation device. The ultraviolet lamp is installed in the ultraviolet oxidation device, and the regenerated water with the oxidant is irradiated through the ultraviolet lamp. The oxidant includes the following mass fractions: Divide: 6.0% hydrogen peroxide, 42.0% peroxodisulfate, 2.0% chloramine and 50.0% water.

[0025] The concentration of urea in reclaimed water is 83ppb;

[0026] The addition of oxidizing agent is Y=5.1ln(83)+2.9=25.4ppm, gets 25ppm;

[0027] The hydraulic retention time in the UV oxidation device is 120s;

[0028] The irradiation dose is Z=3.4(83) 0.8 =116.6mJ / cm 2 , take 119mJ / cm 2 ;

[0029] After testing, the TOC concentration of the product water was 10.9ppb.

[0030] Pass the product water into the resin column. After testing, the TOC concentration of the resin column effluent is 3.7ppb, and the urea concentration is 13ppb;...

Embodiment 3

[0032] The regenerated water obtained after UF+RO treatment is added with an oxidant and then passed into the ultraviolet oxidation device. The ultraviolet lamp is installed in the ultraviolet oxidation device, and the regenerated water with the oxidant is irradiated through the ultraviolet lamp. The oxidant includes the following mass fractions: Divide: 6.0% hydrogen peroxide, 42.0% peroxodisulfate, 2.0% chloramine and 50.0% water.

[0033] The concentration of urea in reclaimed water is 68ppb;

[0034] The addition of oxidizing agent is Y=5.1ln(68)+2.9=24.4ppm, gets 25ppm;

[0035] The hydraulic retention time in the UV oxidation device is 120s;

[0036] The irradiation dose is Z=3.4(68) 0.8 =99.4mJ / cm 2 , take 100mJ / cm 2 ;

[0037] After testing, the TOC concentration of the product water was 9.7ppb.

[0038] Pass the product water into the resin column. After testing, the TOC concentration of the resin column effluent is 2.9ppb, and the urea concentration is 8ppb; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com