Modified lignin particle emulsion as well as preparation method and application thereof

A technology of lignin and kraft lignin, applied in the field of modified lignin particle emulsion and its preparation, and preparation of surface sizing agent suitable for surface enhancement of medical dialysis paper and favorable for sealing, which can solve the problem of high cost and achieve improvement Air permeability, good sizing effect, good air permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of modified lignin particle emulsion of the present embodiment, described method specifically comprises the following steps:

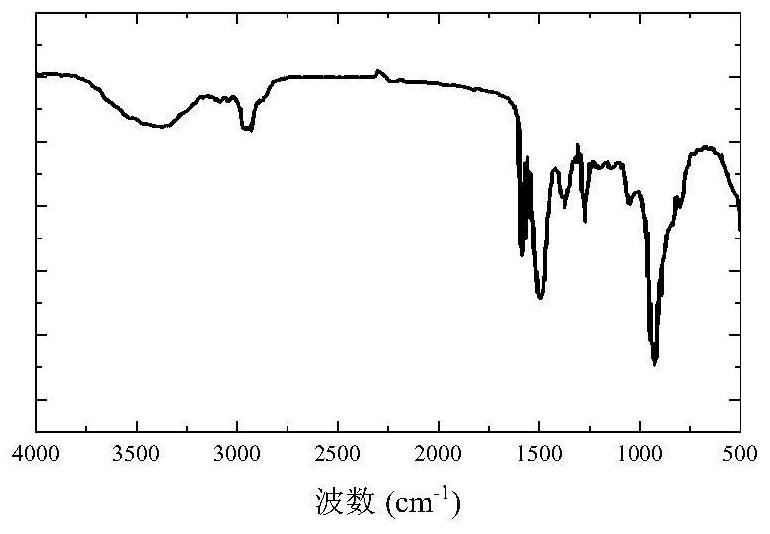

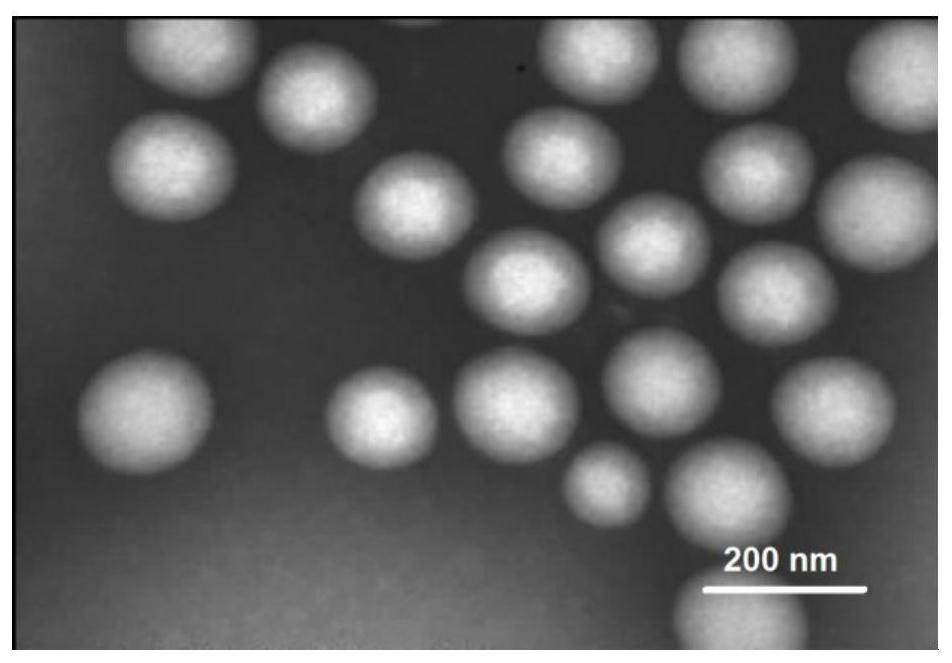

[0043] Dissolve 10g of kraft lignin in 200mL of deionized water, adjust the pH value of the resulting mixture to 10, make it fully dissolved and filter to obtain a kraft lignin solution; pour the kraft lignin solution into an electric Stirrer, serpentine reflux condenser, thermometer, and a four-necked flask with high-purity nitrogen inlet and outlet, heat up to 70°C, add mixed modified monomers (3g of butyl acrylate, methacryloyloxyethyl trimethyl chloride Ammonium chloride 1g, stearyl acrylate 4g, styrene 4g), stirred and emulsified for 30min; Potassium sulfate initiator, the dropping time is 30 minutes; after the dropping, continue to react the reaction system at 70°C for 1.5h, the total reaction time is 2h; then raise the temperature of the system to 80°C and keep it warm for 2h to obtain the modified The lignin...

Embodiment 2

[0046] A kind of preparation method of modified lignin particle emulsion of the present embodiment, described method specifically comprises the following steps:

[0047] Dissolve 10g of kraft lignin in 200mL deionized water, adjust the pH value of the resulting mixture to 9, make it fully dissolved and filter to obtain a kraft lignin solution; pour the kraft lignin solution into an electric Stirrer, serpentine reflux condenser, thermometer, and a four-necked flask with high-purity nitrogen inlet and outlet, heat up to 80°C, add mixed modified monomers (2g of butyl acrylate, methacryloyloxyethyl trimethyl chloride Ammonium chloride 1g, stearyl acrylate 2g, styrene 5g), stir and emulsify for 40min; Add 1.5% potassium persulfate initiator dropwise, and the dropping time is not less than 1h; after the dropping, continue to react the reaction system at 80°C, the total time between the dropping time and the continued reaction is 6h; then continue the system After 4 hours of heat pr...

Embodiment 3

[0050] A kind of preparation method of modified lignin particle emulsion of the present embodiment, described method specifically comprises the following steps:

[0051] Dissolve 10g of kraft lignin in 200mL of deionized water, adjust the pH value of the resulting mixture to 11, fully dissolve and filter to obtain a kraft lignin solution; pour the kraft lignin solution into an electric Stirrer, serpentine reflux condenser, thermometer, and a four-necked flask with high-purity nitrogen inlet and outlet, heat up to 60°C, add mixed modified monomers (2g of butyl acrylate, methacryloyloxyethyl trimethyl chloride After ammonium chloride 1g, stearyl acrylate 3g, styrene 3g), stir and emulsify for 50min; Slowly add 2% potassium persulfate initiator dropwise, and the dropping time is not less than 1h. After the dropping, the reaction system is continued to react at 70°C. The total time between the dropping time and the continued reaction is 4h, and then the system is Raise the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com