Method for rapidly preparing hydrogen bond organic framework material based on electric field, and application thereof

An organic framework and hydrogen preparation technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of tight dialysate supply, low efficiency of removing toxins, and more waste liquid, and achieve short removal time and high chemical and chemical efficiency. Thermal stability, improve removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

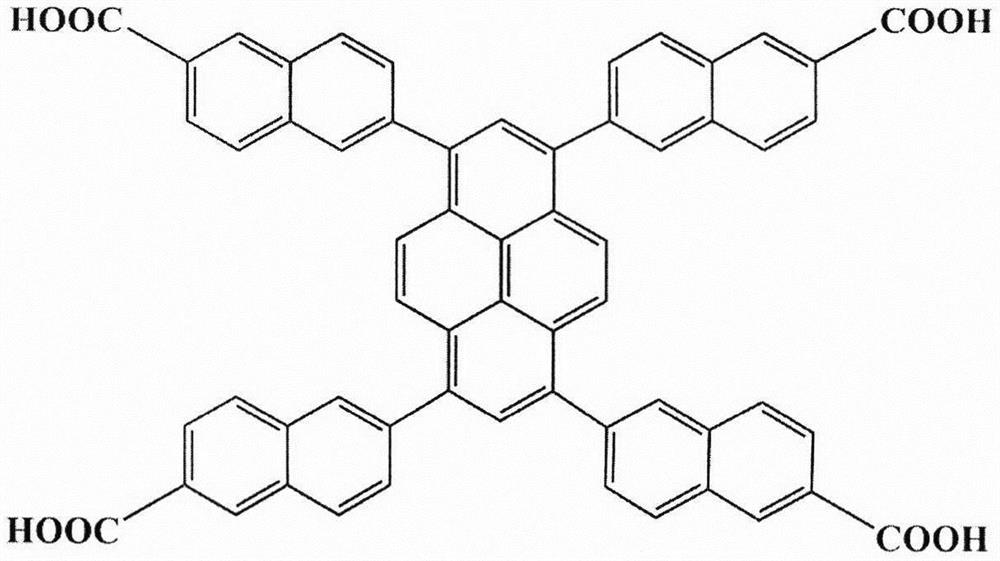

[0030] (1) Weigh 50mg of 1,3,6,8-tetrakis(6-carboxynaphthalene)pyrene and add it to a beaker, measure 15mL N,N'-dimethylformamide and add it to a beaker In a beaker of the organic ligand, ultrasonically disperse until the organic ligand is completely dissolved.

[0031] (2) Under the condition of stirring at 300 rpm, add 80 mL of acetone measured into the above beaker. Adjust the rotational speed to 50 rpm, and use a DC power supply to feed 25V DC into the beaker for 4 hours.

[0032] (3) The product was separated by centrifugation, the rotation speed was 8000 rpm, and the centrifugation time was 7 minutes, and the product was washed with 30 mL of acetone, centrifuged again, and repeated three times. The obtained hydrogen-bonded organic framework material was vacuum-dried at 60° C., and the yield was 82.8%.

Embodiment 2

[0034] (1) Weigh 200mg of 1,3,6,8-tetrakis(6-carboxynaphthalene)pyrene and add it to a beaker, and add the measured 50mLN,N'-dimethylformamide into the organic Ligand in a beaker and ultrasonically disperse until the organic ligand is completely dissolved.

[0035] (2) Under the condition of stirring at 400 rpm, add 240 mL of acetone measured into the above beaker. Adjust the rotation speed to 50 rpm, and use a DC power supply to pass 70V direct current into the beaker for 2 hours.

[0036] (3) The product was separated by centrifugation, the rotating speed was 8000 rpm, and the centrifugation time was 7 minutes, and the product was washed with 50 mL of acetone, centrifuged again, and repeated three times. The obtained hydrogen-bonded organic framework material was vacuum-dried at 60° C., and the yield was 85.4%.

Embodiment 3

[0038] (1) Weigh 100mg of 1,3,6,8-tetrakis(6-carboxynaphthalene)pyrene and add it to a beaker, and add the measured 20mL dimethyl sulfoxide to the beaker containing the organic ligand , ultrasonically dispersed until the organic ligands were completely dissolved.

[0039] (2) Under the condition of stirring at 400 rpm, add 60 mL of tetrahydrofuran measured into the above beaker. Adjust the rotation speed to 50 rpm, and use a DC power supply to feed a 50V DC power into the beaker for 3 hours.

[0040] (3) The product was separated by centrifugation, the rotation speed was 8000 rpm, and the centrifugation time was 7 minutes, and the product was washed with 40 mL of acetone, centrifuged again, and repeated three times. The obtained hydrogen-bonded organic framework material was vacuum-dried at 60° C., and the yield was 79.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com