Preparation method of anisotropic structural color film for myocardial mechanical sensing

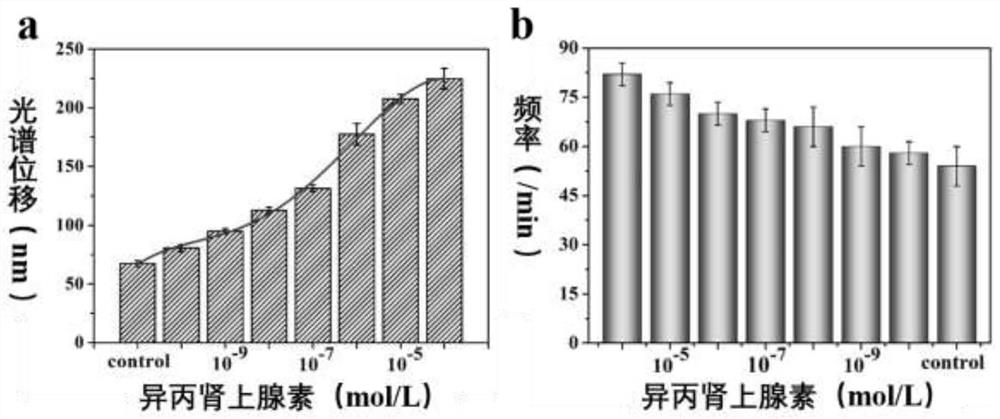

An anisotropic and structural color technology, applied in the field of preparation of anisotropic structural color films, can solve the problems of decreased reliability of results, mechanical damage of cells, high cost requirements, etc., to promote the transmission of intercellular signals and induce orientation Results with high growth, precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

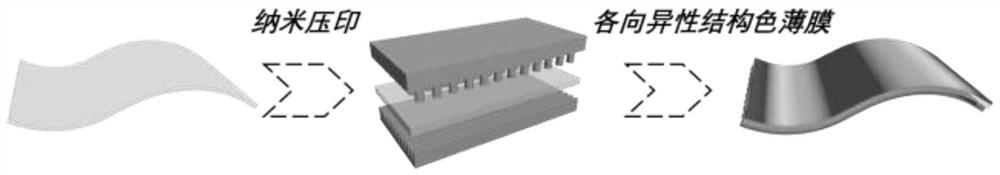

[0028] The invention provides a method for preparing an anisotropic structural color thin film for myocardial mechanical sensing, comprising the following steps:

[0029] 1) Preparation of flexible film substrate: select thermoplastic materials with good biocompatibility and strong tensile properties, such as polyurethane, nitrocellulose, etc., use organic solvents to prepare a solution with a certain concentration, and then spin coat the solution evenly by spin coating On a plasma-treated glass sheet, and then heated on a hot stage to evaporate the solvent to obtain a cured flexible film substrate;

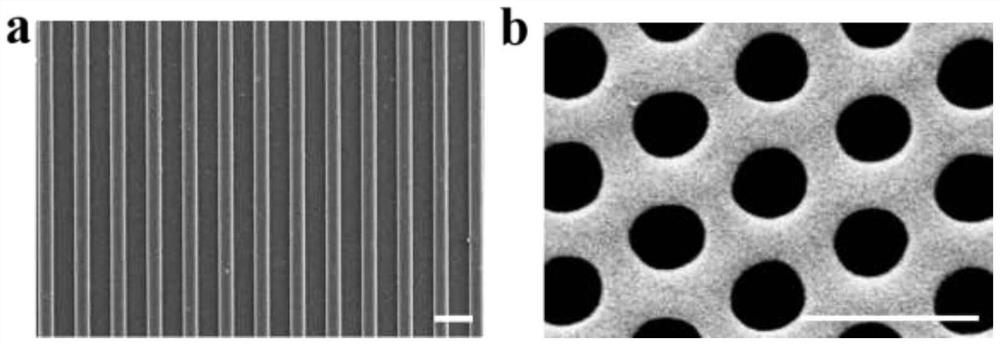

[0030] 2) Preparation of anisotropic structural color film for myocardial mechanical sensing: use step 1 to prepare a flexible film substrate and two precision-processed templates, one is a micron-scale groove structure, and the other is an orderly array of nano-scale Cylindrical structure, the flexible film substrate is sandwiched between two templates (the groove template is on...

Embodiment 1

[0041] An anisotropic structural color film for myocardial mechanical sensing with polyurethane as a skeleton material is prepared according to the following method:

[0042] (1) Preparation of polyurethane pregel solution

[0043] Dissolve solid or semi-solid polyurethane in N,N-dimethylformamide solvent with a final concentration of 6wt%, place the mixed solution on a magnetic stirrer, and mix and stir at 65°C until the polyurethane is completely dissolved to obtain a uniform Polyurethane pregel solution.

[0044] (2) Preparation of flexible film substrate

[0045] Treat the clean glass sheet with plasma for 5 minutes, then prepare a thin film on the surface of the glass sheet with the prepared polyurethane solution by spin coating method, place the film on a hot stage at 65°C for 2 hours, and cure the film by solvent evaporation , to obtain a flexible film substrate.

[0046] (3) Preparation of anisotropic structural color thin film

[0047] The flexible film substrate pr...

Embodiment 2

[0051] An anisotropic structural color thin film for myocardial mechanical sensing with nitrocellulose as a skeleton material is prepared according to the following method:

[0052] (1) Preparation of nitrocellulose gel solution

[0053] Solid nitrocellulose was dissolved in acetone and N,N-dimethylformamide mixed solvent (1:1, v / v), the final concentration was 7% (wt%), and the mixed solution was placed under magnetic stirring Mix and stir until the nitrocellulose is completely dissolved to obtain a uniform nitrocellulose pregel solution.

[0054] (2) Preparation of flexible film substrate

[0055] Treat the clean glass sheet with plasma for 5 minutes, and then spin-coat the prepared nitrocellulose solution to form a film on the surface of the glass sheet. Put the film on a hot stage at 65°C and heat it for 2 hours. The film is cured to obtain a flexible film substrate.

[0056] (3) Preparation of anisotropic structural color thin film

[0057] The flexible film substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com