Preparation method of photocatalytic magnesium cementing material, and product thereof

A magnesia cementitious material and a technology for the cementitious material, which are applied in the field of photocatalytic magnesia cementitious material preparation and its products, can solve the problem of air pollutants not having the ability to purify, and are beneficial to photocatalytic decomposition and improve durability. , high photogenerated carrier separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

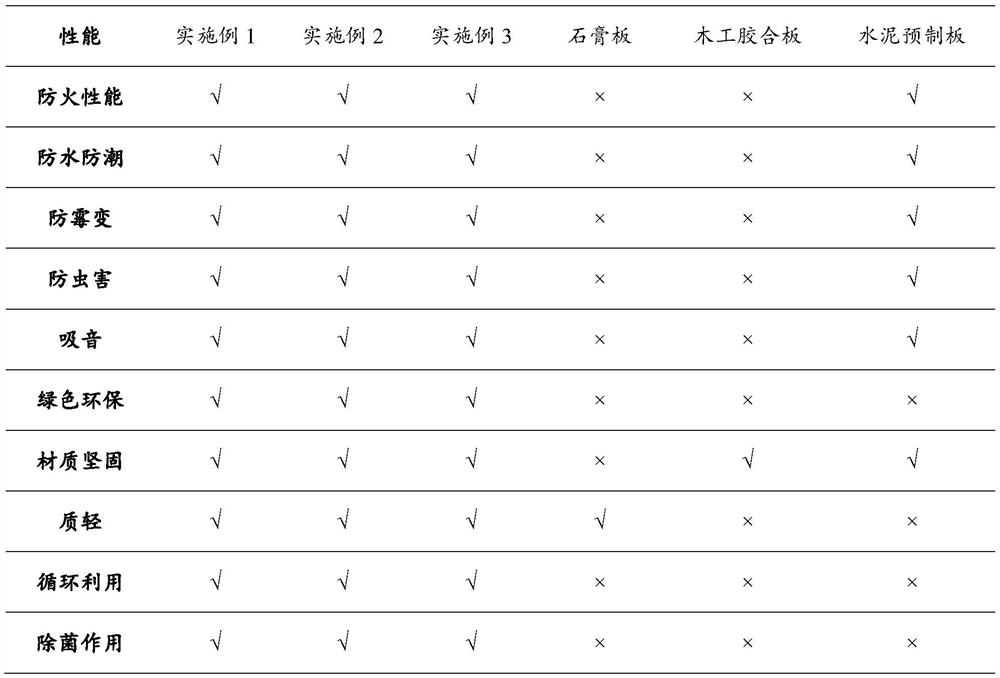

Embodiment 1

[0038] Take 100 parts by weight of magnesium oxide powder, 120 parts of magnesium sulfate solution, 12 parts of aluminum oxide powder, 6 parts of hemp fiber, 5 parts of perlite, 2.6 parts of titanium dioxide, 3 parts of foaming agent, titanium dioxide-boron modified carbon nitride 12 parts of photocatalyst. First add magnesium oxide powder to water, then add alumina powder and titanium dioxide and stir at a high speed of 2000rpm for 15 minutes, then add magnesium sulfate solution, hemp fiber and perlite and continue stirring for 5 minutes, and finally add AC foaming liquid with a concentration of 10%. Stir at a low speed of 600 rpm for 10 minutes to obtain a magnesia gelled slurry. Then pour the magnesia gelling slurry into the mold, comb it flat, lay non-woven fabric on the surface of the slurry, and then roll it to make the slurry compact; then put it into the curing room, under the condition of 35 ° C ~ 37 ° C Stand still and gel; after it is solidified and demoulded, the ...

Embodiment 2

[0040] Take 100 parts by weight of magnesium oxide powder, 123 parts of magnesium chloride solution, 10 parts of aluminum oxide powder, 8 parts of bamboo fiber, 6 parts of perlite, 2.8 parts of titanium dioxide, 5 parts of 10% AC foaming liquid, and phosphoric acid bridging composite TiO 2 -BiVO 420 parts of nano photocatalyst. First add magnesium oxide powder to water, then add alumina powder and titanium dioxide and stir at a high speed of 2000 rpm for 10 minutes, then add magnesium chloride solution, bamboo fiber and perlite and continue stirring for 6 minutes, and finally add AC foaming liquid with a concentration of 10% and 5 TiO 2 -BiVO 4 The nano photocatalyst was stirred at a low speed of 600 rpm for 8 minutes to obtain a magnesia gelled slurry. Then pour the magnesia gelling slurry into the mold, comb it flat, lay non-woven fabric on the surface of the slurry, and then roll it to make the slurry compact; then put it into the curing room, under the condition of 35 ...

Embodiment 3

[0042] Take 100 parts by weight of magnesium oxide powder, 125 parts of magnesium chloride solution, 8 parts of aluminum oxide powder, 10 parts of coconut fiber, 7 parts of perlite, 2.9 parts of titanium dioxide, 4 parts of 10% AC foaming liquid, phosphoric acid functional carbon 32 parts of nanotube-titanium dioxide composite nano photocatalyst. First add magnesium oxide powder to water, then add alumina powder and titanium dioxide and stir at a high speed of 2000rpm for 20 minutes, then add magnesium chloride solution, bamboo fiber and perlite and continue stirring for 5 minutes, and finally add AC foaming liquid with a concentration of 10%. Stir at a low speed of 600 rpm for 5 minutes to obtain a magnesia gelled slurry. Then pour the magnesia gelling slurry into the mold, comb it flat, lay non-woven fabric on the surface of the slurry, and then roll it to make the slurry compact; then put it into the curing room, under the condition of 35 ° C ~ 37 ° C Stand still and gel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com