A kind of titanium alloy self-lubricating composite film and preparation method thereof

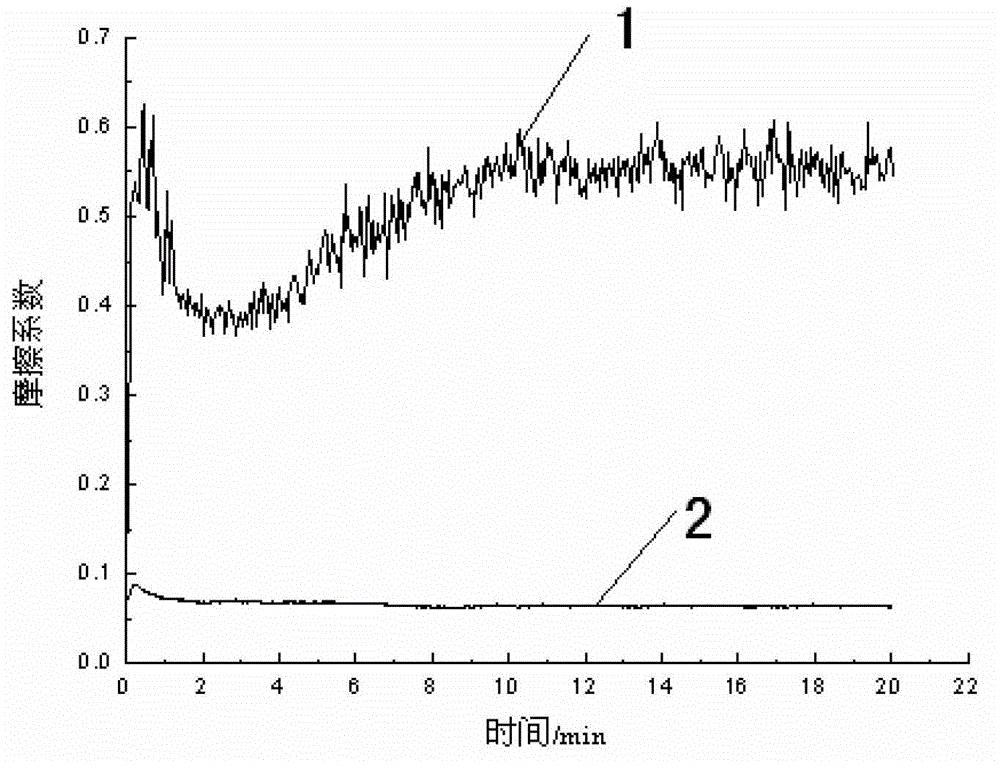

A technology of titanium alloy and composite film, which is applied in the field of titanium alloy antifriction and wear resistance, can solve the problems of complex preparation process, large friction coefficient, and unsuitability for industrialized large-scale production, and achieve simple equipment, good lubrication and antifriction performance, and reduce Effect of Coefficient of Friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

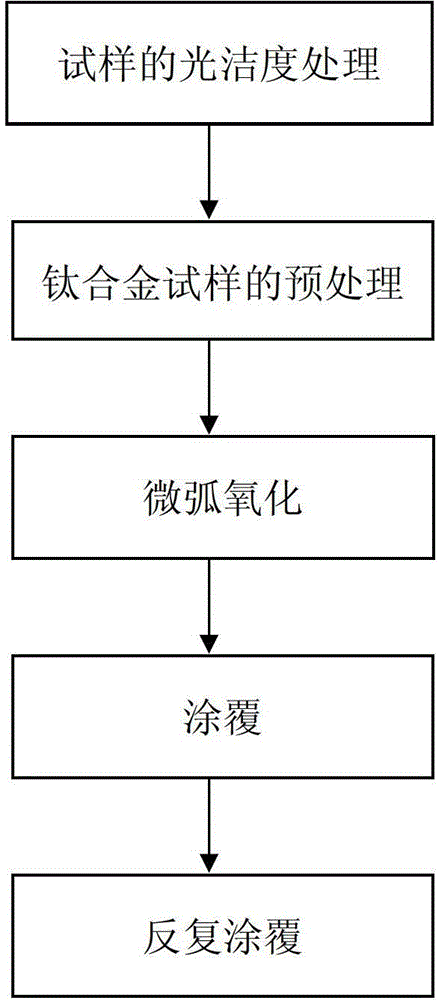

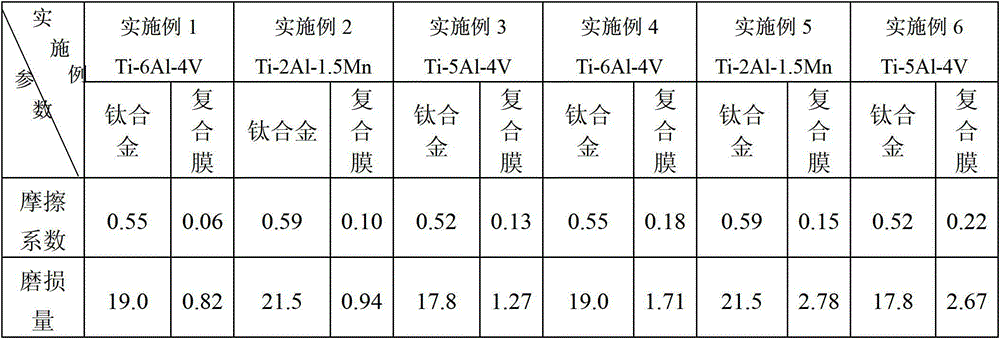

[0038] This embodiment is a Ti6Al4V titanium alloy self-lubricating composite film, and the external dimensions of the sample are 25mm×20mm×2.5mm.

[0039] The self-lubricating composite film is composed of a ceramic oxide film and an epoxy resin-based composite material coating, and the ceramic oxide film is prepared on the surface of the titanium alloy sample, and the epoxy resin-based composite material coating is prepared on the surface of the ceramic oxide film .

[0040] The ceramic oxide film contains 19.20-24.59% of Ti, 50.16-55.38% of O, 6.63-8.24% of P, 6.98-9.53% of Si and 7.74-9.46% of Al. In this embodiment, the ceramic oxide film contains 21.59% Ti, 53.38% O, 7.64% P, 7.53% Si, and 8.86% Al.

[0041] The Ti in the ceramic oxide film is mainly derived from the matrix, P and Si are respectively derived from sodium silicate and sodium hexametaphosphate in the electrolyte components, and the content of O in the film layer is relatively high, indicating that micro-ar...

Embodiment 2

[0058] This embodiment is a Ti-2Al-1.5Mn titanium alloy self-lubricating composite film, and the external dimensions of the sample are 25mm×20mm×2.5mm.

[0059] The self-lubricating composite film is composed of a ceramic oxide film and an epoxy resin-based composite material coating, and the ceramic oxide film is prepared on the surface of the titanium alloy sample, and the epoxy resin-based composite material coating is prepared on the surface of the ceramic oxide film .

[0060] The ceramic oxide film contains 19.0-24.59% of Ti, 50.16-55.38% of O, 6.6-8.24% of P, 6.98-9.53% of Si and 7.74-9.46% of Al. In this embodiment, the ceramic oxide film contains 24.12% Ti, 50.16% O, 6.98% P, 9.53% Si, and 8.21% Al.

[0061] The Ti in the ceramic oxide film is mainly derived from the matrix, P and Si are respectively derived from sodium silicate and sodium hexametaphosphate in the electrolyte components, and the content of O in the film layer is relatively high, indicating that micro-a...

Embodiment 3

[0077] This embodiment is a Ti-5Al-4V titanium alloy self-lubricating composite film, and the external dimensions of the sample are 25mm×20mm×2.5mm.

[0078] The self-lubricating composite film is composed of a ceramic oxide film and an epoxy resin-based composite material coating, and the ceramic oxide film is prepared on the surface of the titanium alloy sample, and the epoxy resin-based composite material coating is prepared on the surface of the ceramic oxide film .

[0079] The ceramic oxide film contains 19.0-24.59% of Ti, 50.16-55.38% of O, 6.6-8.24% of P, 6.98-9.53% of Si and 7.74-9.46% of Al. In this embodiment, the ceramic oxide film contains 19.20% Ti, 53.43% O, 8.24% P, 9.18% Si, and 8.95% Al.

[0080] The Ti in the ceramic oxide film is mainly derived from the matrix, P and Si are respectively derived from sodium silicate and sodium hexametaphosphate in the electrolyte components, and the content of O in the film layer is relatively high, indicating that micro-ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com