Experimental device for reducing nano bubbles on coal surface and improving biological gas production and working method thereof

A technology of nanobubbles and experimental devices, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of low rate, difficult product removal, etc., to promote the elimination of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

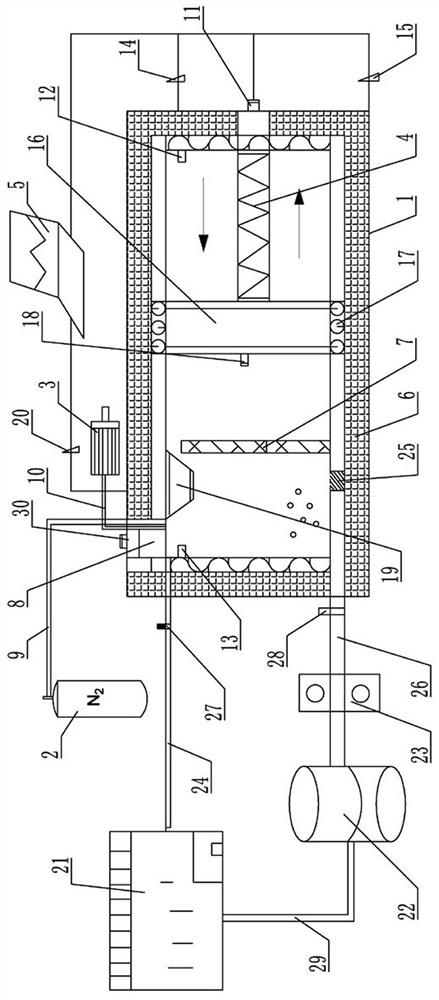

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the experimental device for reducing nano-bubbles on the coal surface and improving biogas production includes biogas production box 1, nitrogen cylinder 2, vacuum pump 3, mobile barrier assembly, telescopic mechanical arm 4, bubble monitoring system, and gas-liquid collection test system and computer 5, the biogas generation box 1 is a cuboid box with a sandwich structure, the sandwich structure is an electric heating interlayer 6 (electric heating rods are arranged inside the interlayer), and the left side of the middle part of the biogas generation box 1 is fixed with a partition The baffle 7, the partition baffle 7 is parallel to the left side plate of the biogas generation box 1, the partition baffle 7 divides the inside of the biogas generation box 1 into an anaerobic fermentation zone and a pressure regulation zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com